Planetary cycloid pin wheel balance wheel throw-in type barring device

A technology of cycloidal pinwheel and turning device, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of tooth top and tooth top collision, and achieve the effect of solving the problem of tooth top collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

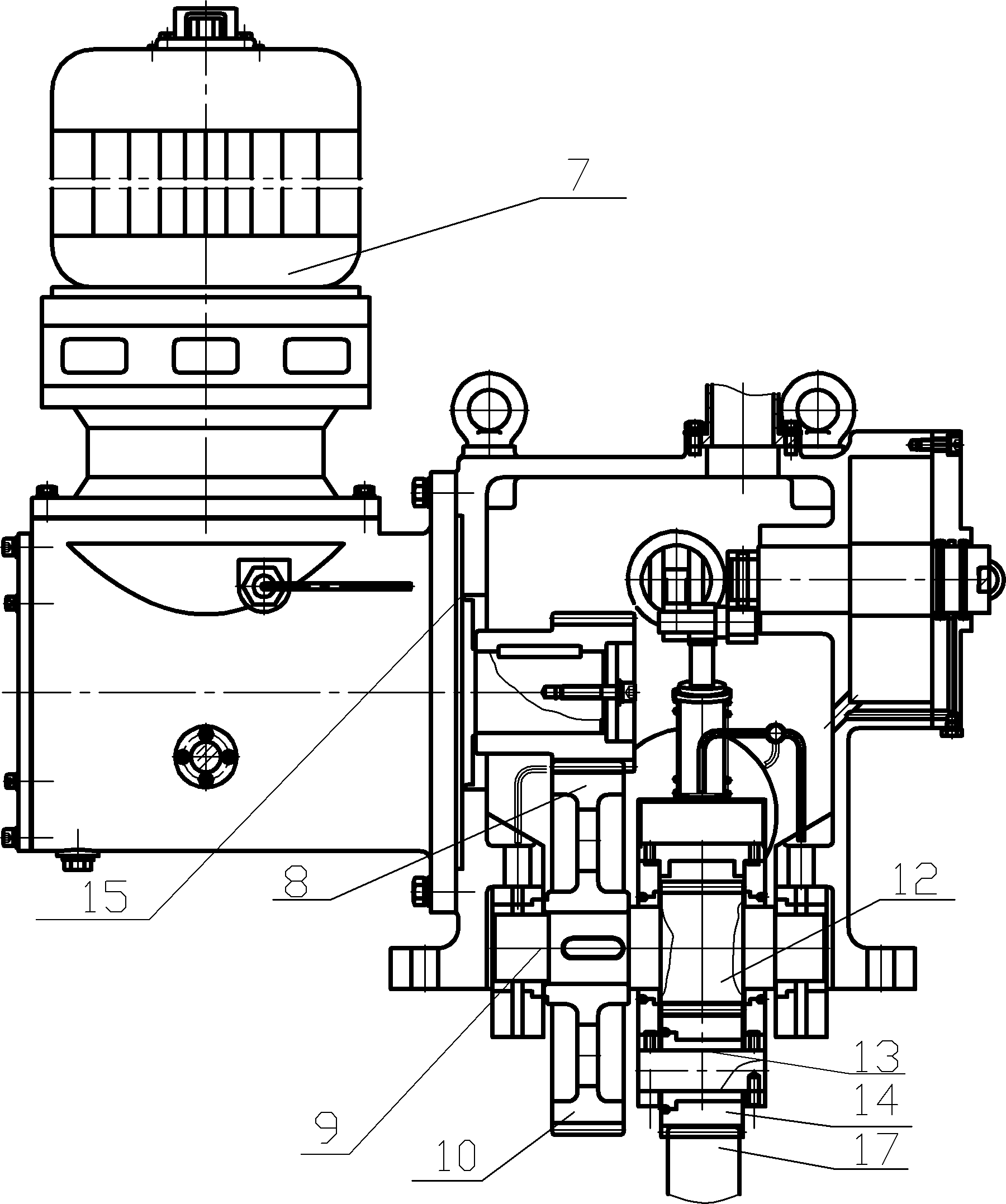

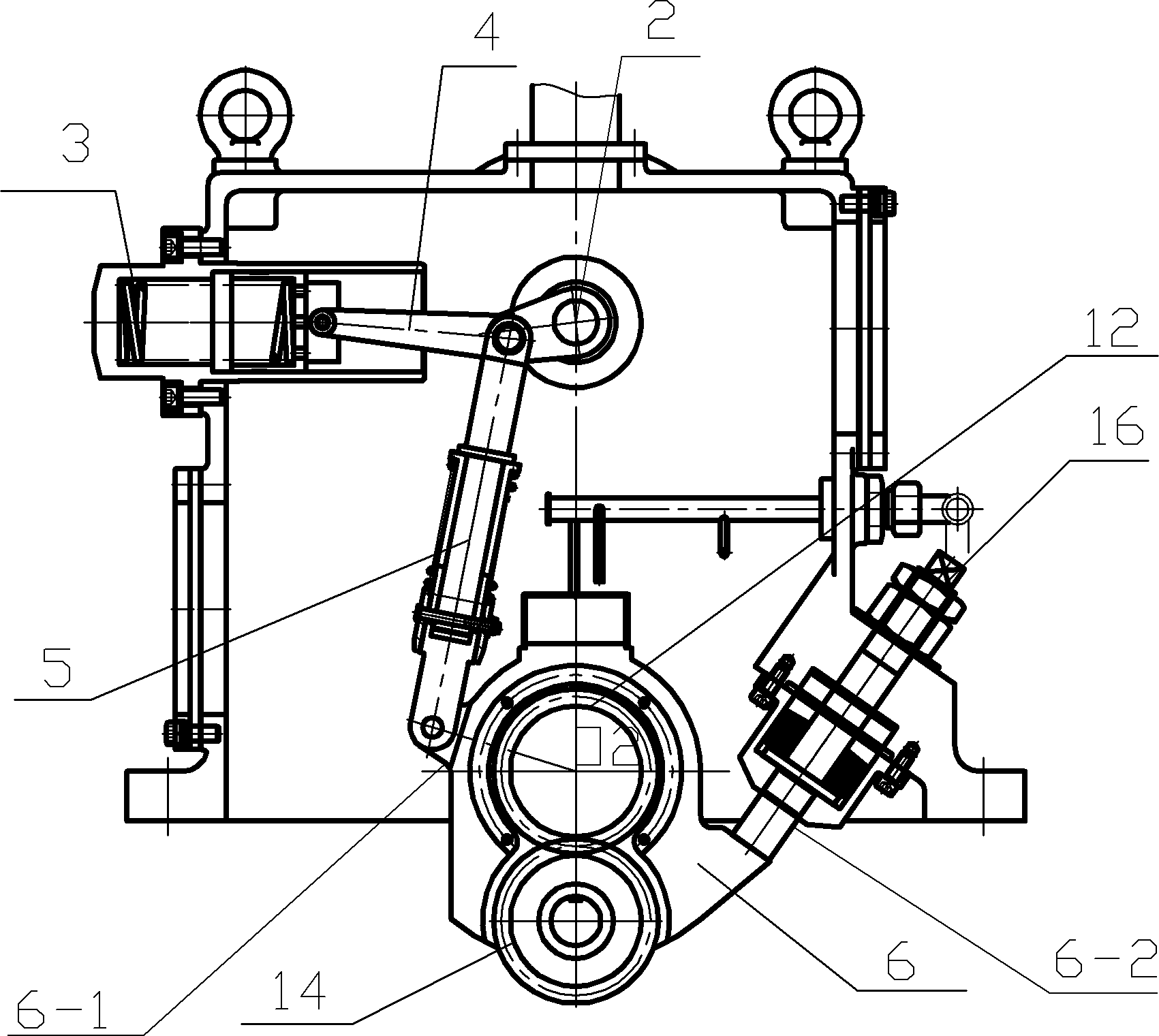

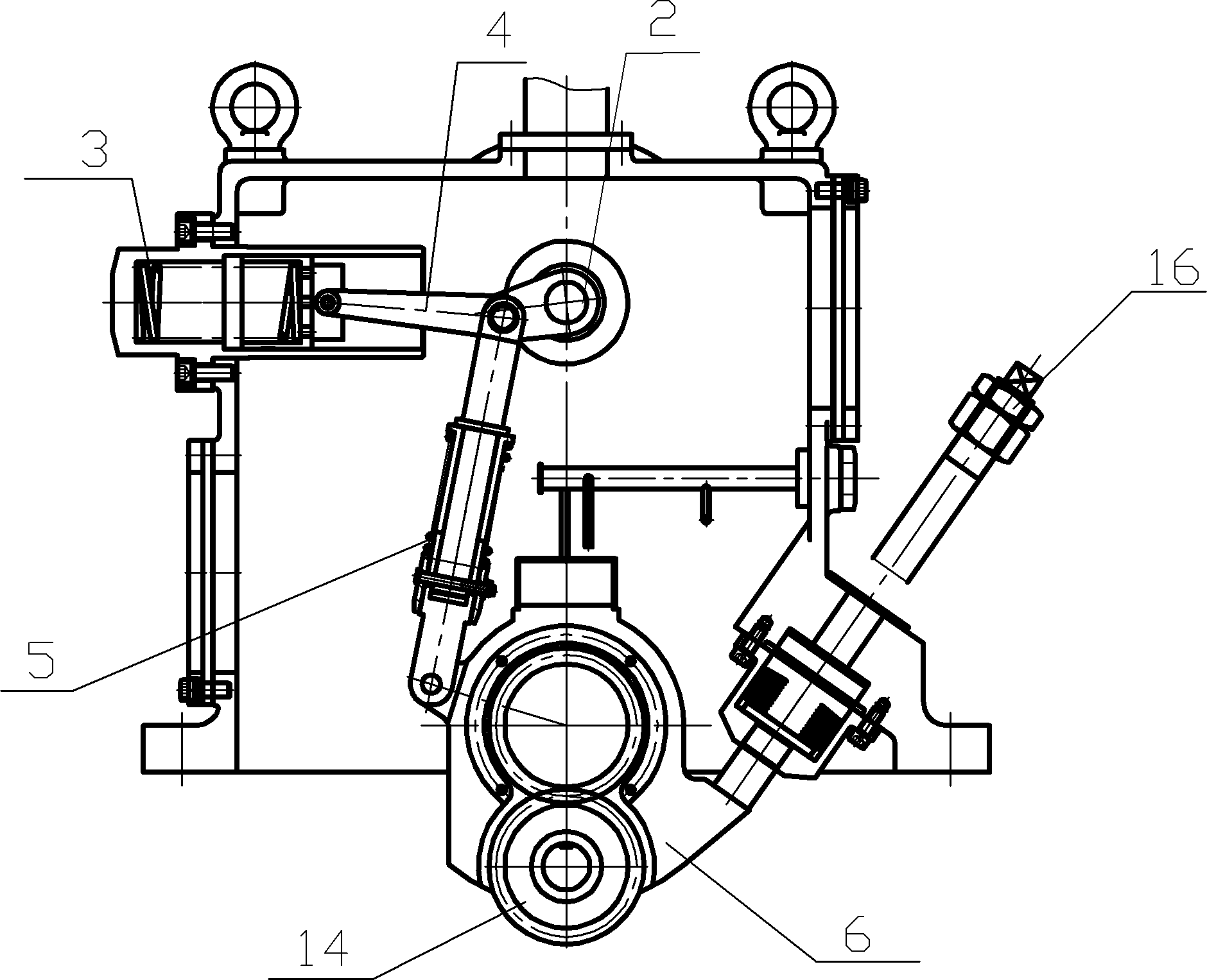

[0008] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, the turning device of this embodiment includes a hand wheel 1, a crank 2, a spring 3, a connecting rod 4, a pull rod 5, a U-shaped swing housing 6, a speed reducer 7, a first gear 8, and a first intermediate shaft 9 , the second gear 10, the third gear 12, the second intermediate shaft 13, the fourth gear 14, the frame 15 and the push rod 16, and the side wall of the U-shaped swing shell 6 near the bottom is provided with a connecting ring 6-1, A sleeve 6-2 is provided on the other side wall of the U-shaped oscillating shell 6, and the handwheel 1 is connected to one end of the crank 2 in transmission, and the other end of the crank 2 is connected to the spring 3 and the upper end of the connecting rod 4 respectively, and the spring 3 installed above the frame 15, the lower end of the connecting rod 4 is connected with the upper end of the tie rod 5, and the lower end of the tie ...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 The present embodiment will be described. The swing angle of the U-shaped swing case 6 of the present embodiment is 120°. Other implementation manners are the same as the specific implementation manner 1.

[0011] Working principle: when the turning device is working, the reducer 7 drives the fifth gear 17 to rotate through the first gear 8, the second gear 10, the third gear 12 and the fourth gear 14, and the fifth gear 17 is set outside the coupling of the steam turbine edge, thus driving the rotor to rotate, the third gear 12 can only bear the driving of the motor, and rotate around the central axis of the U-shaped swing shell 6. Regardless of whether the third gear 12 rotates or not, the U-shaped swing housing 6 can rotate around its central axis. The fourth gear 14 can not only rotate around its own center, but also can swing under the action of external force. The input or withdrawal of the barring device de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com