Tensile flexible pipe

A tension and hose technology, applied in the direction of hoses, hose connection devices, pipes, etc., can solve the problems of harsh supply operation environment, discount of hose performance and service life, and mutual dragging of supply ships and receiving ships, etc. The effect of saving replenishment operation time, improving cargo transmission capacity, and avoiding ship collision accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

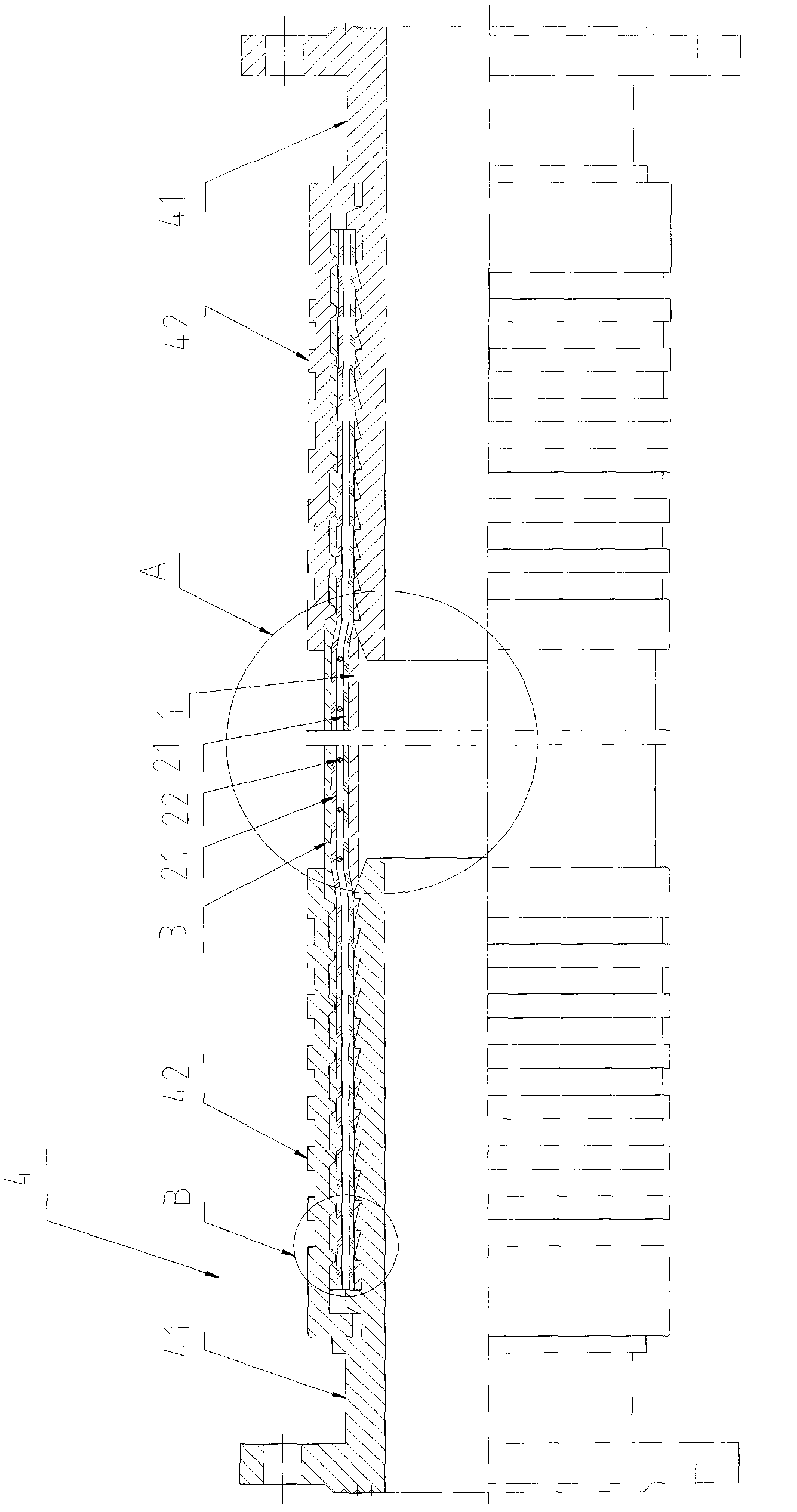

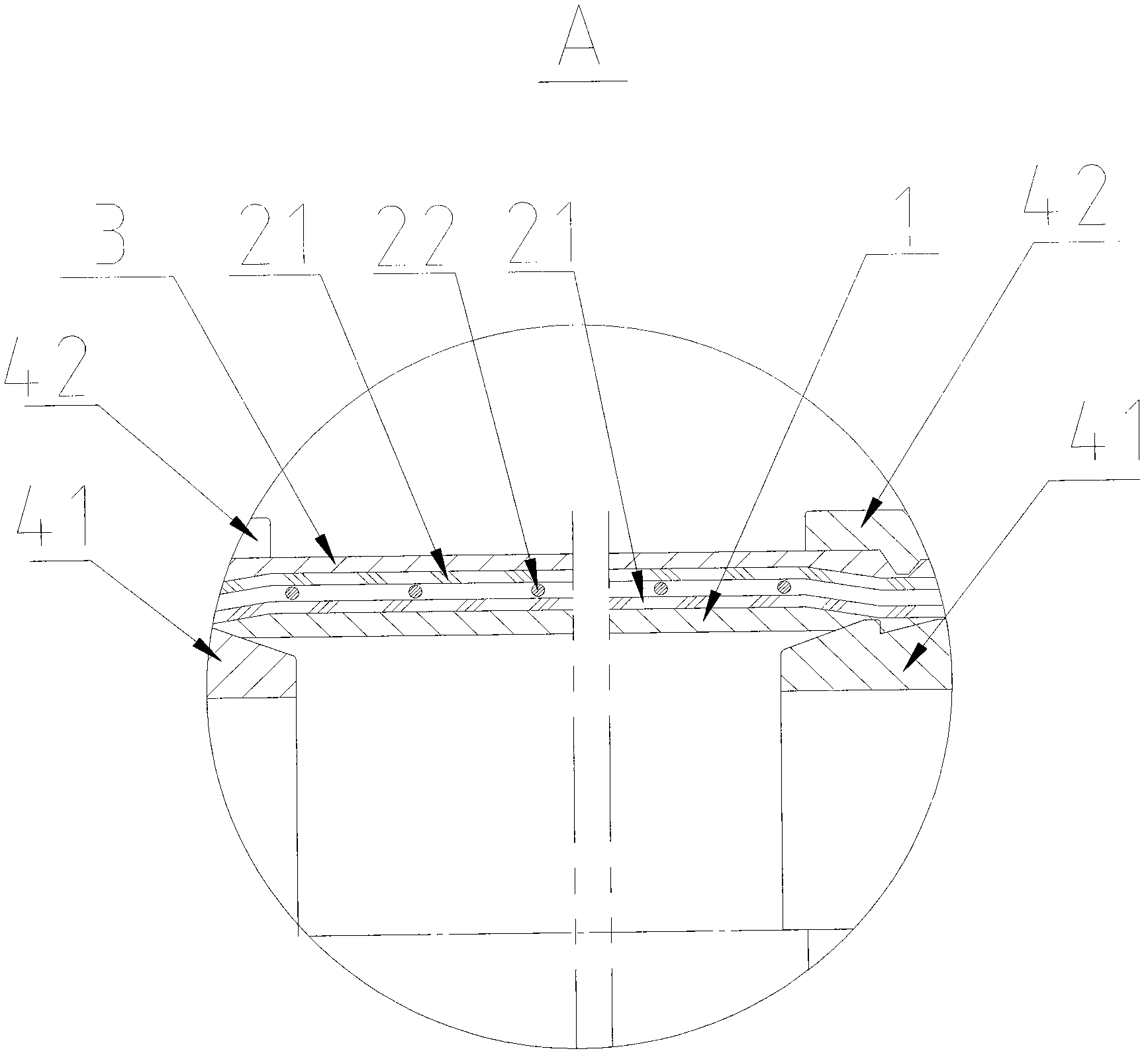

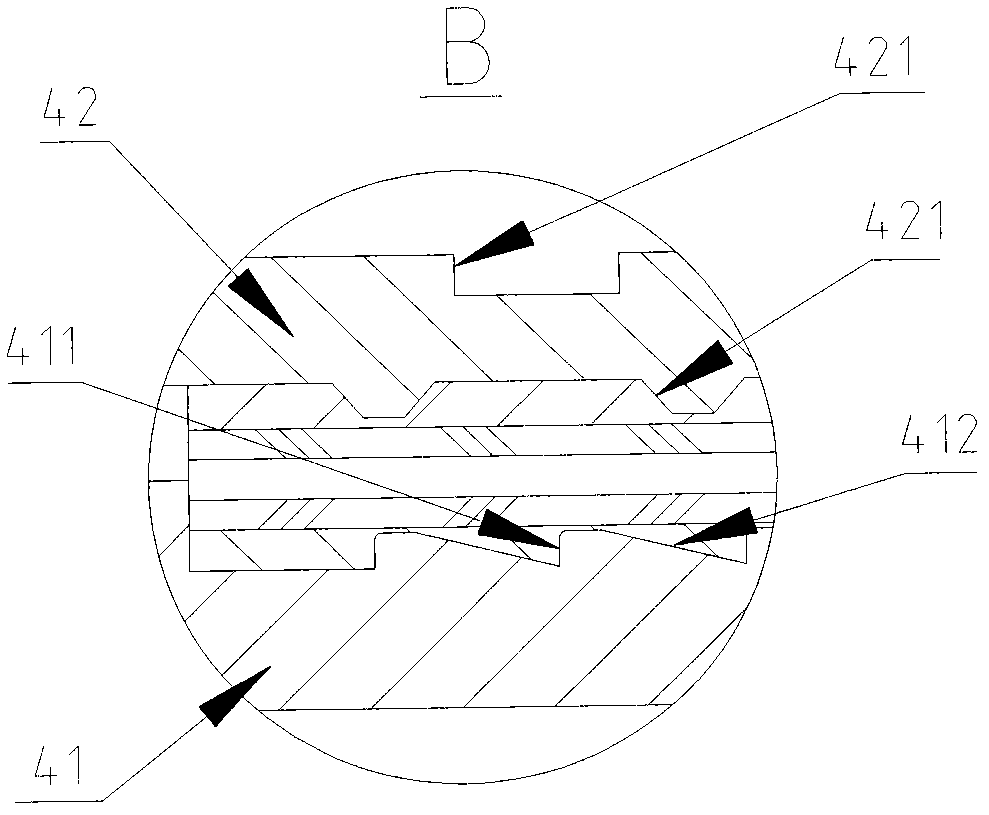

[0038] figure 1 It is a structural schematic diagram of an embodiment of the tension hose according to the present invention; figure 2 Yes figure 1 The enlarged schematic diagram of part A shown; image 3 Yes figure 1 An enlarged schematic view of part B is shown.

[0039] like Figure 1 to Figure 3 As shown, the present invention provides a tension hose, which sequentially includes an inner rubber layer 1, a skeleton layer and an outer rubber layer 3 from inside to outside, and is characterized in that the skeleton layer includes a fiber layer 21 and is sandwiched between the fiber layers The metal spiral layer 22 in the middle of 21, the inner rubber layer 1 is used to transport the liquid medium, and has resistance and tightness to the transported liquid medium; the skeleton layer 2 is the supporting structure of the tension hose , to withstand ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com