Reciprocating material feeding type high-concentration dust producer

A reciprocating feeding and high-concentration technology, which is applied in the fields of instruments, scientific instruments, suspensions and porous materials analysis, etc., can solve the problem of small amount of dust generated by the dust generator, which cannot truly reflect the performance of the equipment, and cannot scientifically judge the performance of the dust removal equipment, etc. problems, to achieve the effect of scientific and reasonable dust suppression efficiency inspection and detection, compact structure and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

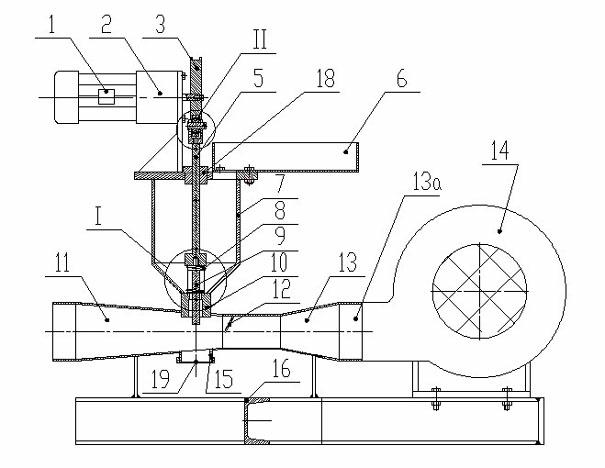

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

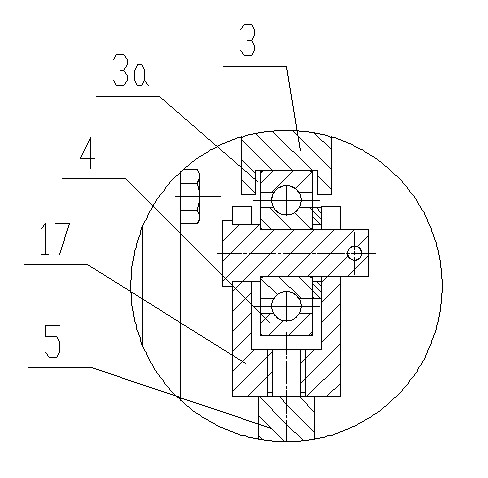

[0027] Such as figure 1 , figure 2 and image 3 As shown, a reciprocating feed type high-concentration dust generator includes a launch tube 11 and an air-inducing tube 13, the air inlet 13a of the air-inducing tube 13 is connected to the blower 14, and the launch tube 11, the air-inducing tube 13 and the blower are connected to the frame 16 fixed connections.

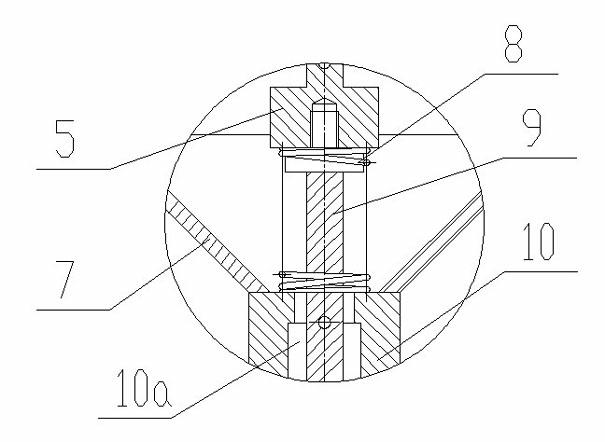

[0028] A shaft sleeve 10 is arranged radially above the emitting tube 11 , and a dust generating rod 9 is arranged inside the shaft sleeve 10 . The inner hole 10a of the shaft sleeve 10 is a stepped hole, and the diameter of the lower end of the stepped hole is larger than that of the upper end. The diameter of the dust generating rod 9 is smaller than the minimum diameter of the inner hole 10a of the shaft sleeve 10 . The size of the dust-generating rod can be selected according to the air volu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com