Patents

Literature

32results about How to "Large amount of dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

NOx emission reduction system based on ignition and sintering of dry mixture

ActiveCN107314677AFully warm upFull drying effectFurnace typesWaste heat treatmentFluidized bedFlue gas

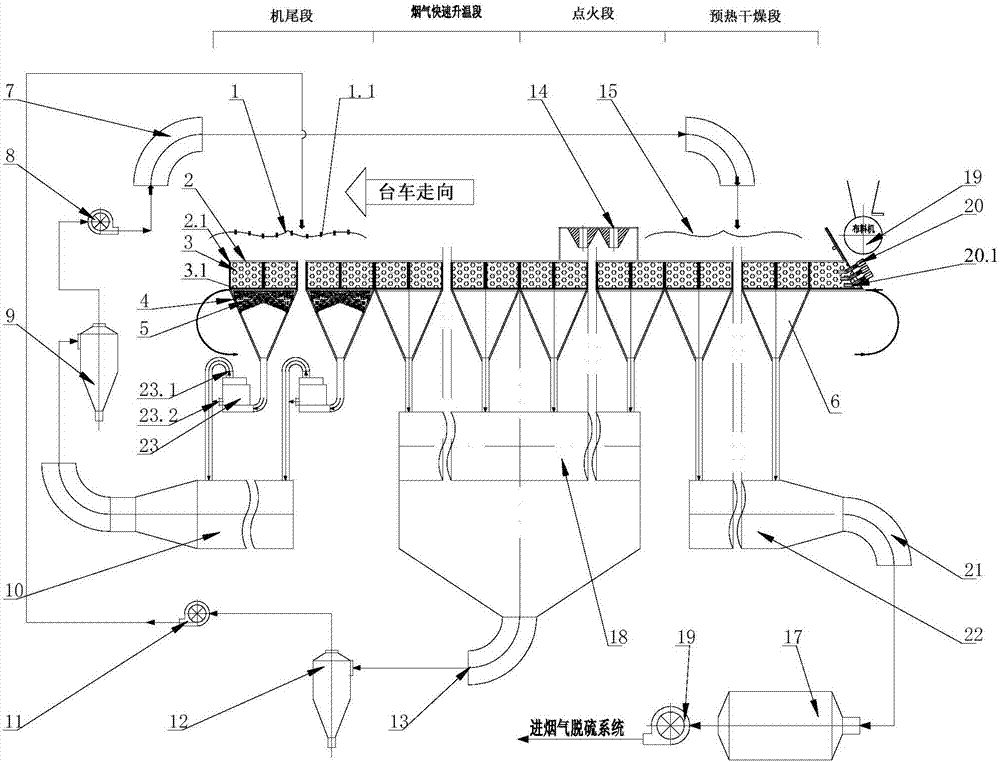

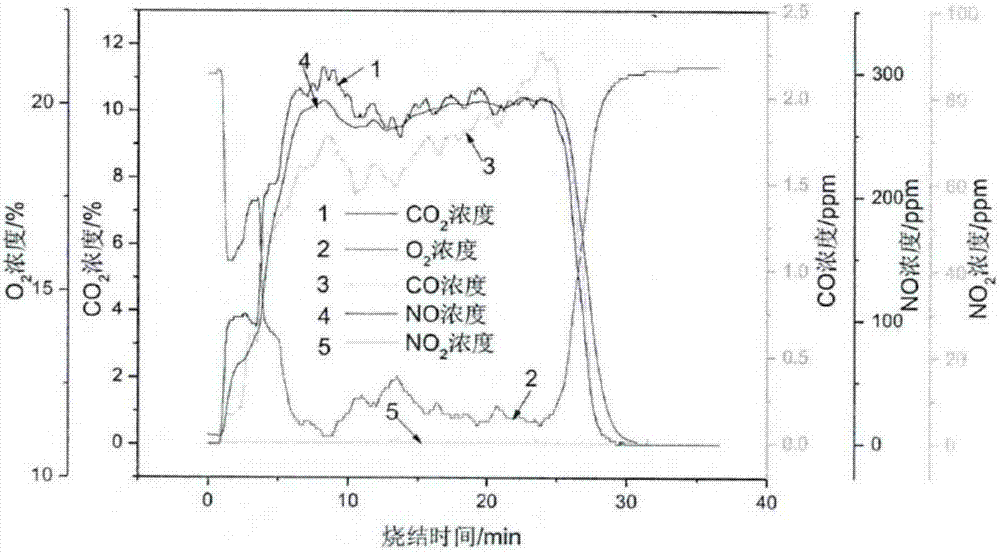

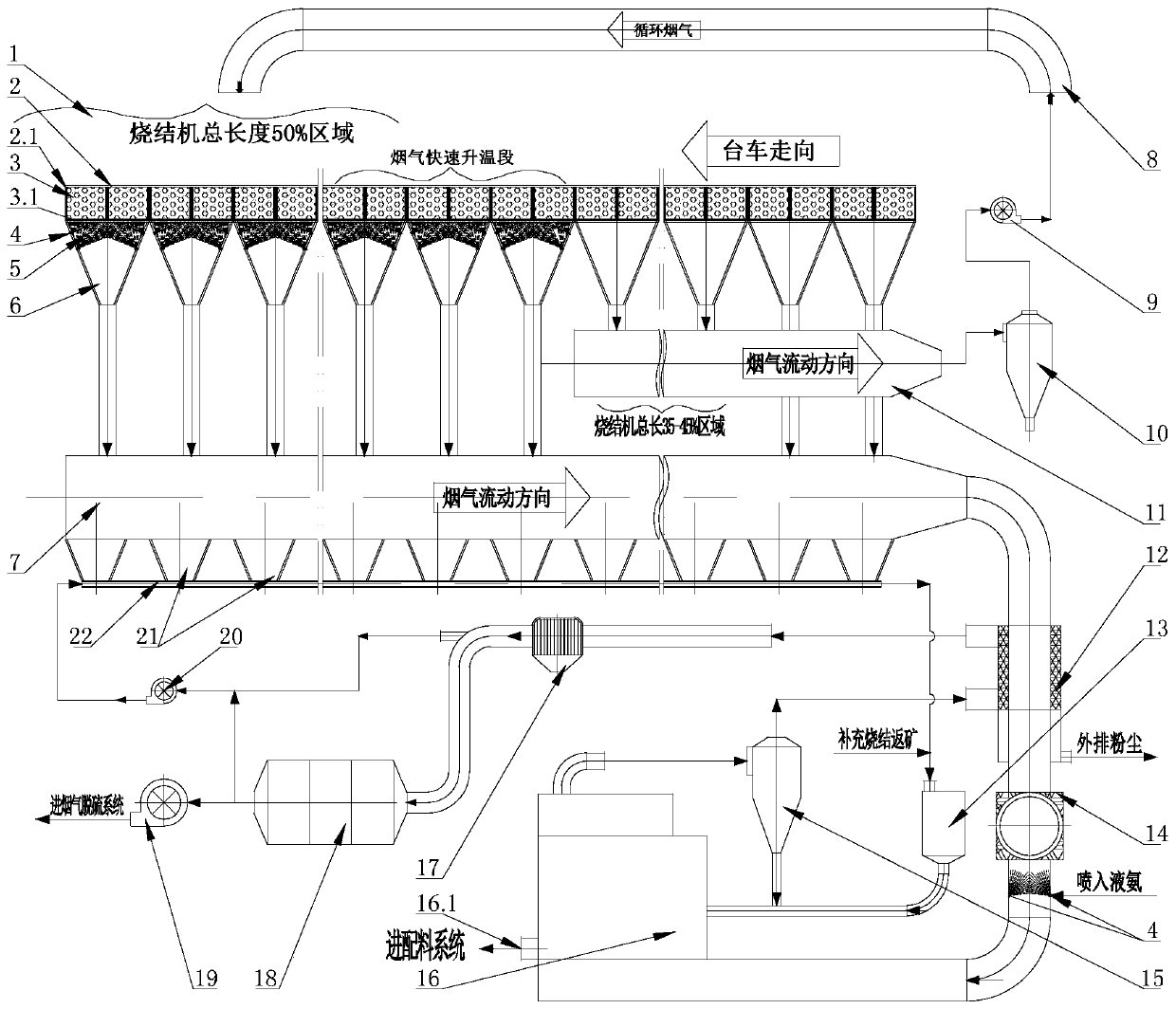

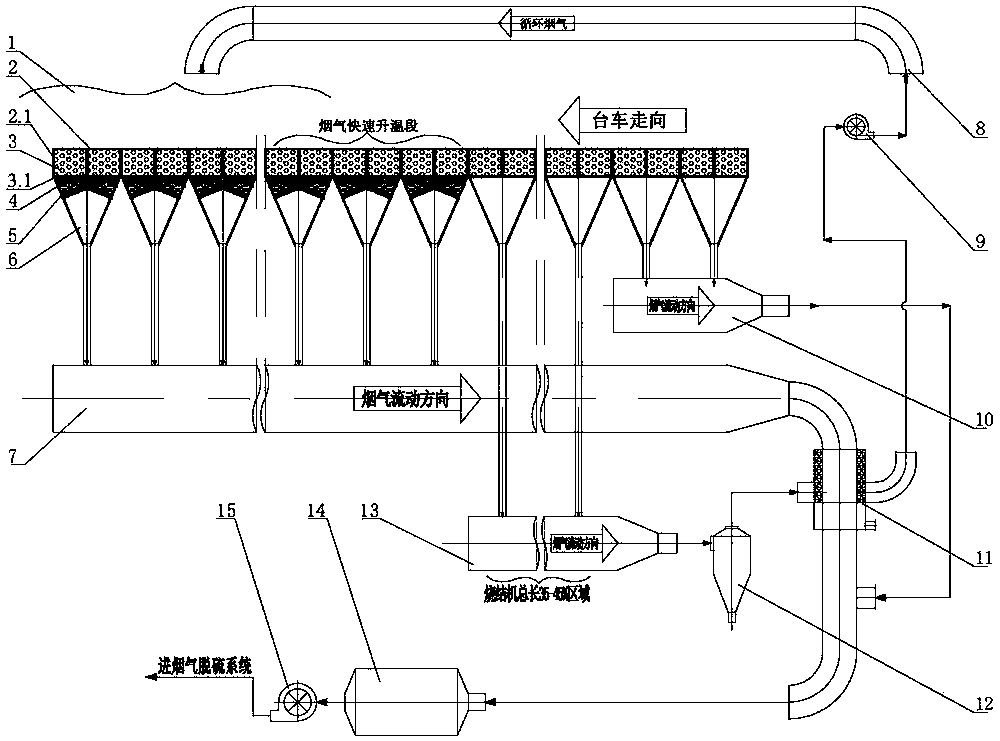

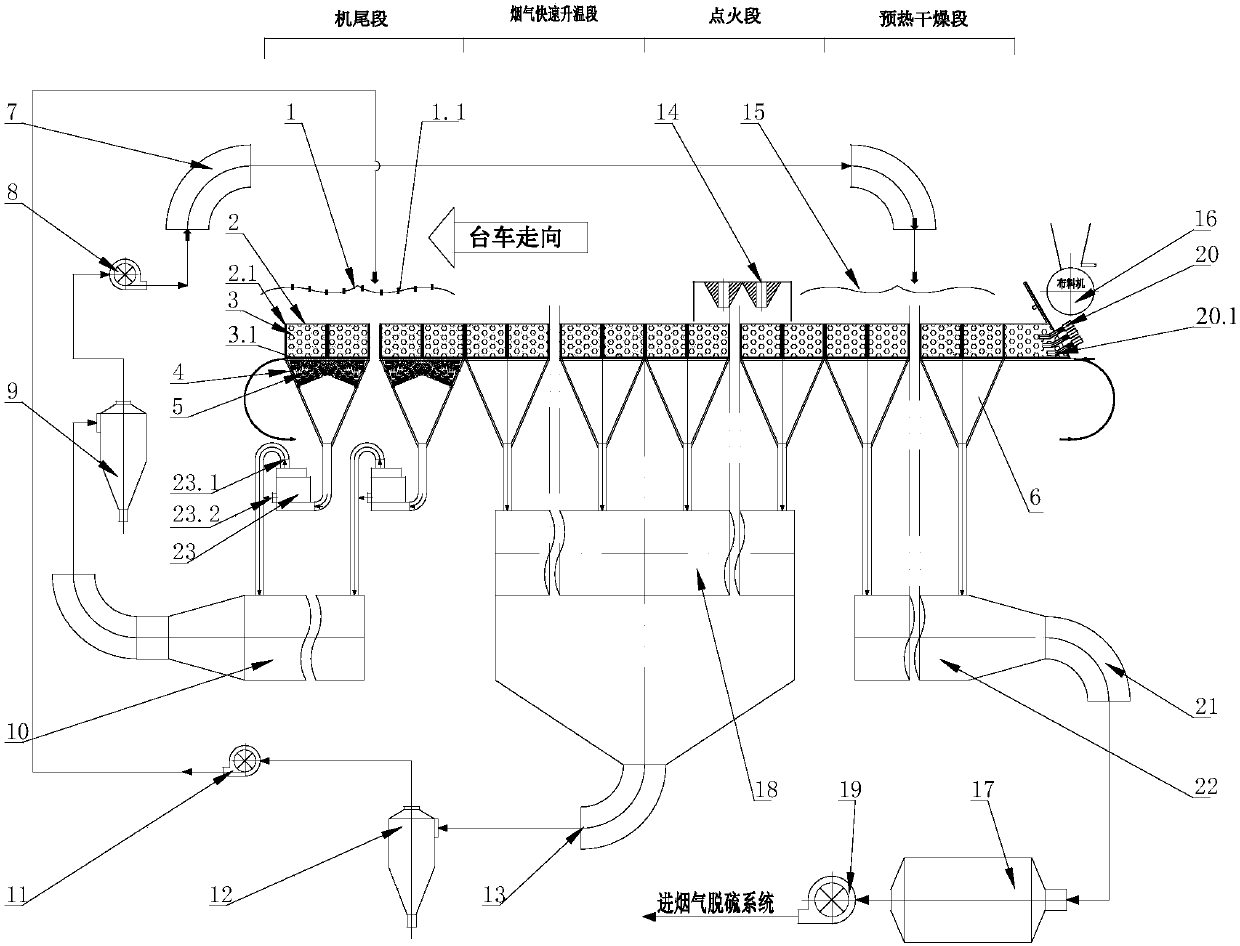

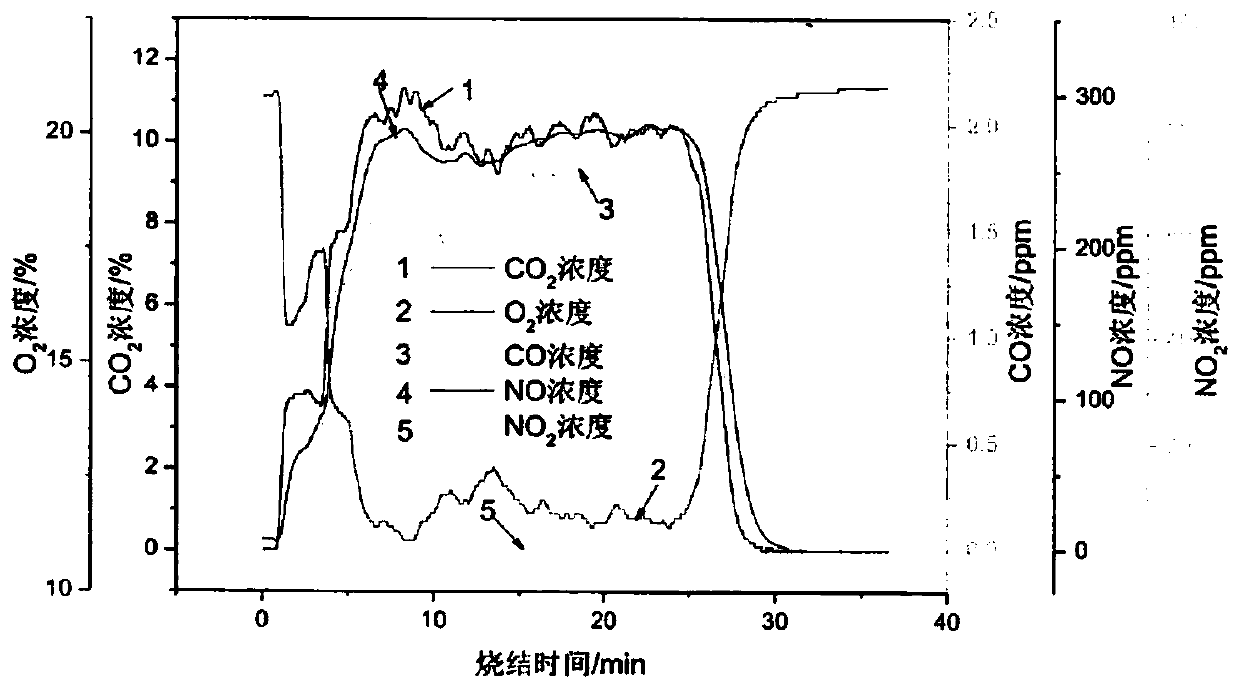

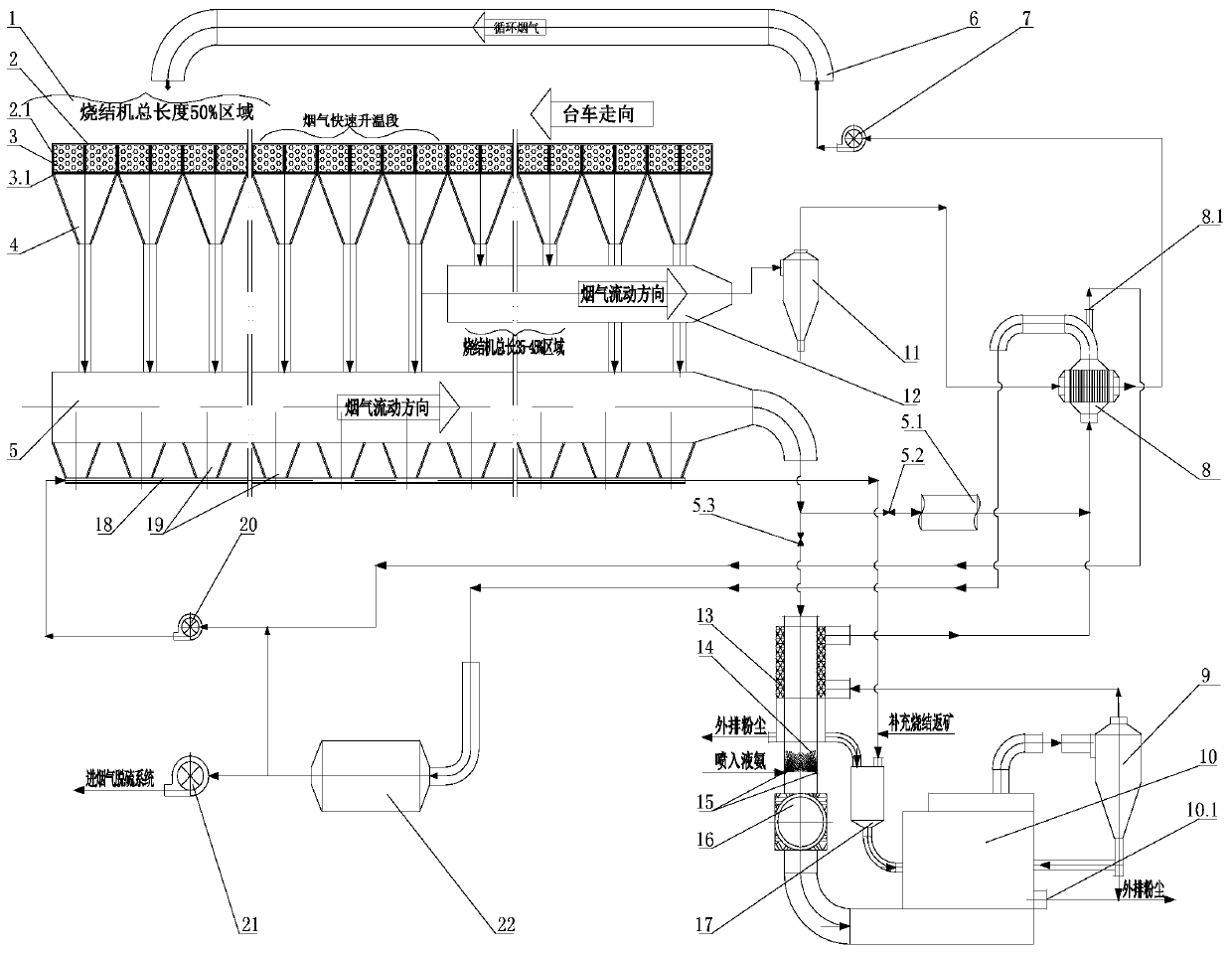

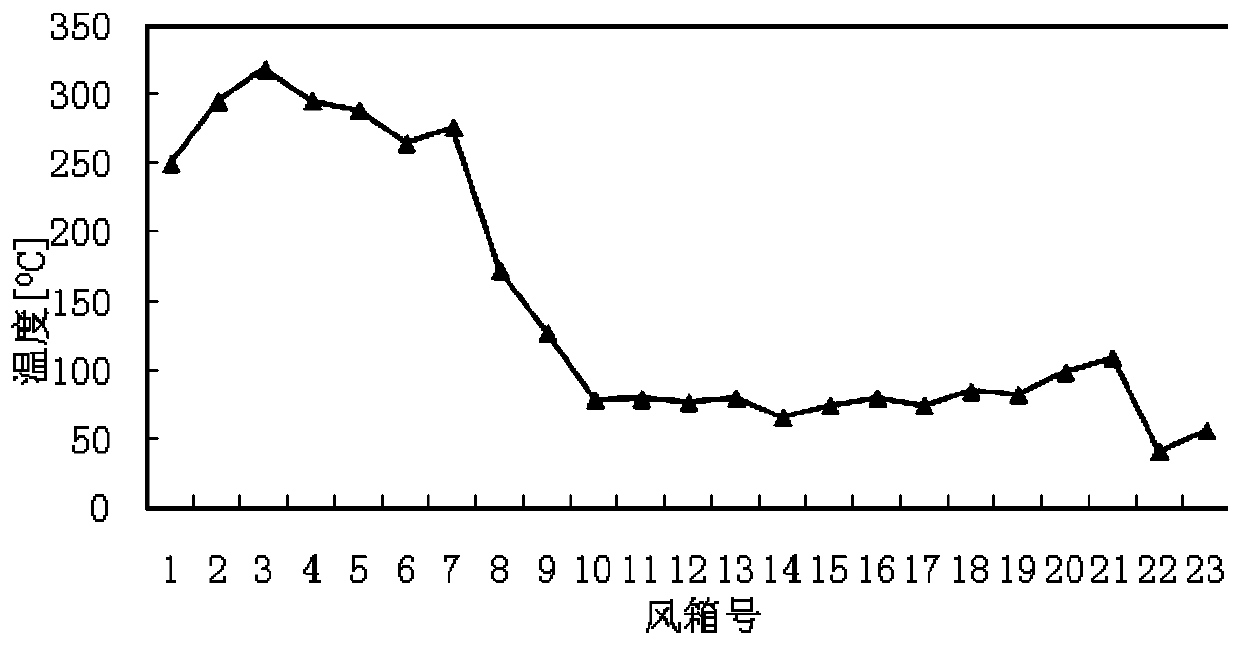

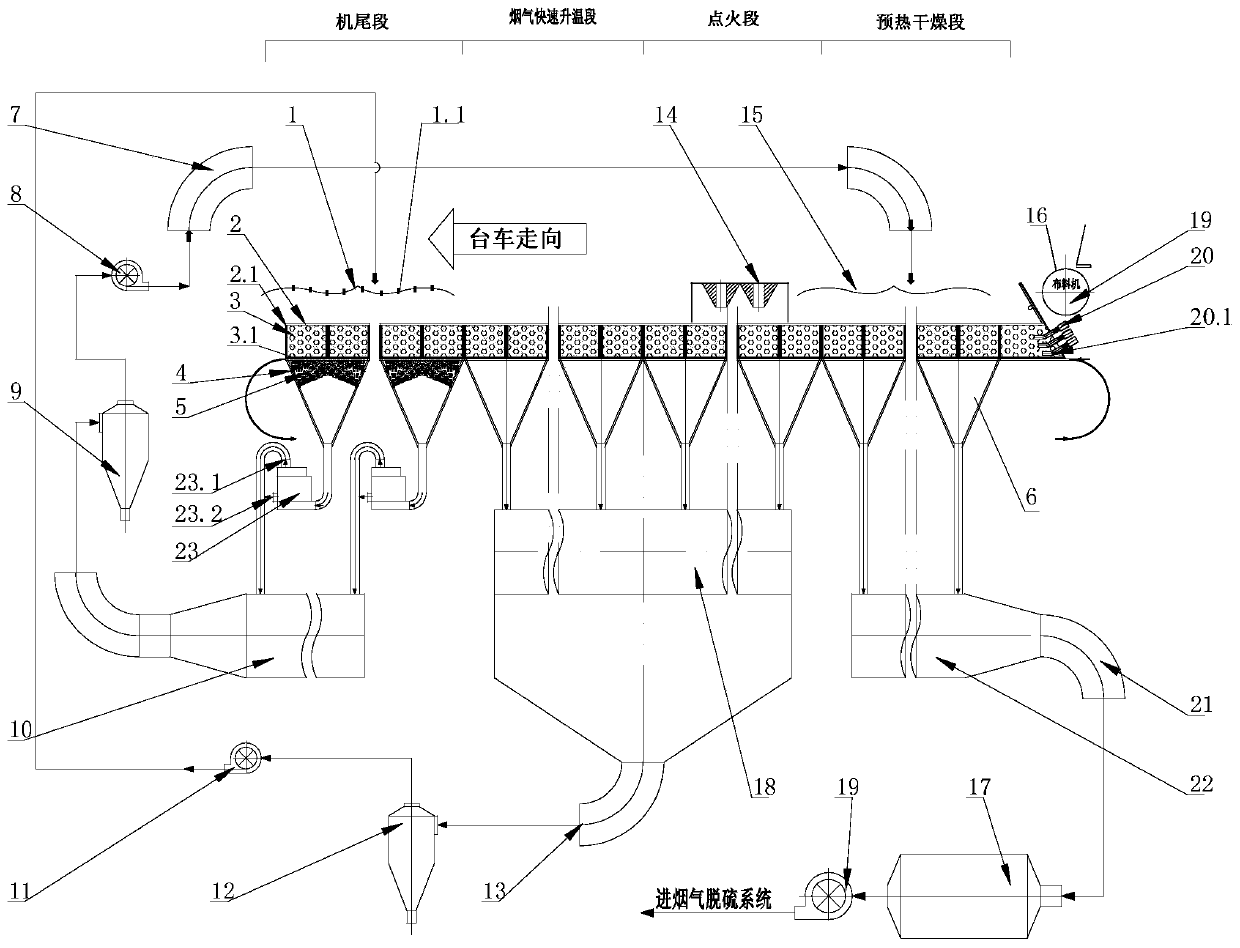

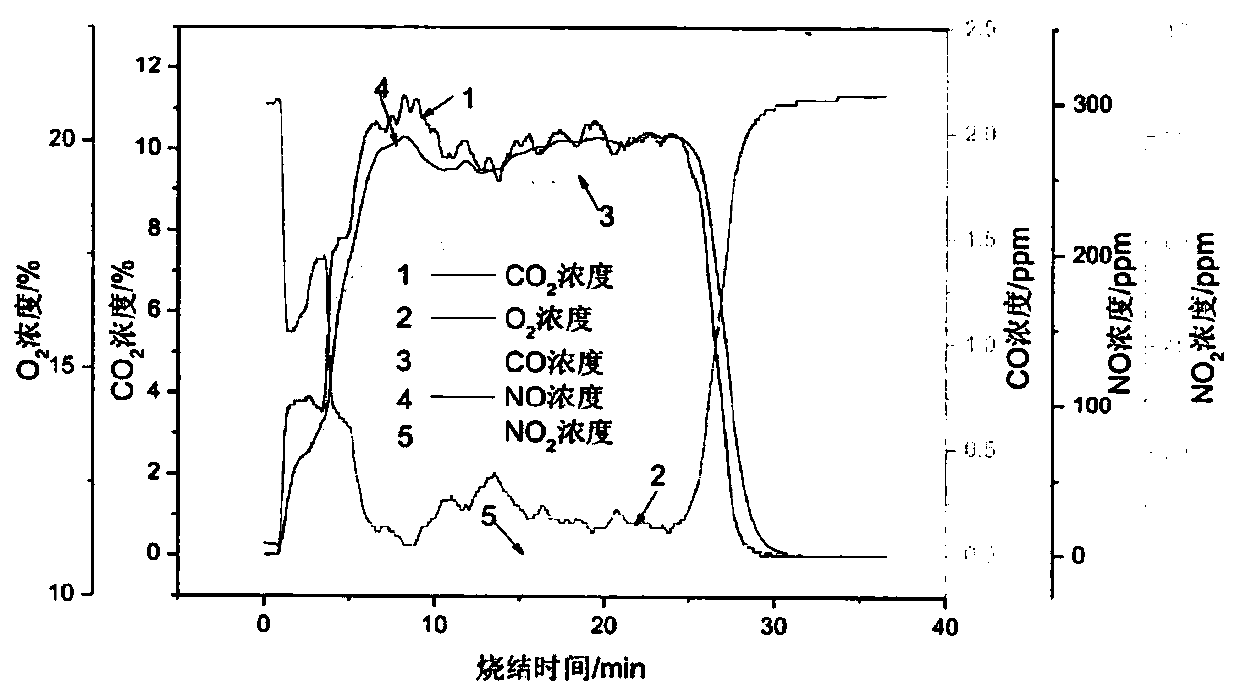

The invention discloses a NOx emission reduction system based on ignition and sintering of a dry mixture. According to the technical scheme, the system comprises a sintering machine; bellows are arranged below trolleys of the sintering machine; the sintering is sequentially divided into four areas including a preheating and drying section, an ignition section, a flue gas quick-heating section and a tail section in the advancing direction of the trolleys; the bellows below the tail section are connected through fluidized bed reactors, a high-temperature flue gas main flue, a high-temperature flue gas dust remover, a high-temperature flue gas circulating fan and a high-temperature flue gas circulating pipe sequentially with a high-temperature circulating flue gas cover located above the preheating and drying section. With the system, the pollution emission amount is small, the recovery rate of waste heat of sintering flue gas is high, no outsourced denitration catalyst is used, and generation of NOx in the flue gas is effectively reduced.

Owner:武汉钢铁有限公司 +2

Paper pouring gate pipe component for casting cast steel

InactiveCN106747522AReduce carbon contentImprove waterproof and moisture-proof performanceFoundry mouldsFoundry coresFiberMullite

The invention discloses a paper pouring gate pipe component for casting cast steel. The paper pouring gate pipe component is prepared from the following raw material in weight percentage: 1 to 70% of inorganic sintered powder material, 1 to 40% of organic fiber, 1 to 20% of inorganic fiber, 1 to 25% of thermocuring material, 1 to 10% of binding agent, 1 to 5% of waterproof and dampproof agent, 1 to 5% of enhancer and filter aid, 1 to 5% of fluxing agent and 0 to 5% of flame retardant, wherein the inorganic sintered powder material is combination of any several kinds of mullite, high-aluminum clay, attapulgite, montmorillonite, bentonite, high-aluminum powder, quartz, volcanic rock and graphite. The paper pouring gate pipe component has no effects of recarburization, decarbonization, carburization and the like on iron, so that chemical ingredients and material performance of cast steel raw materials are prevented from being changed. The paper pouring gate pipe component has the advantages of light weight, easiness to operate, small waste after cast pouring, labor saving, time saving, energy conservation, environmental friendliness, no environmental pollution, environmental protection and the like; in addition, the waste is easy to treat.

Owner:BAOJI HUAGUANG CASTING MATERIAL TECH

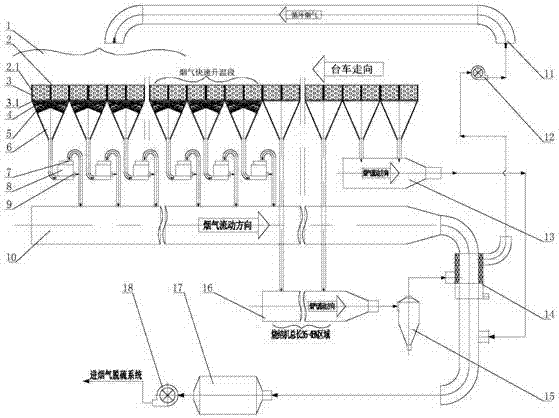

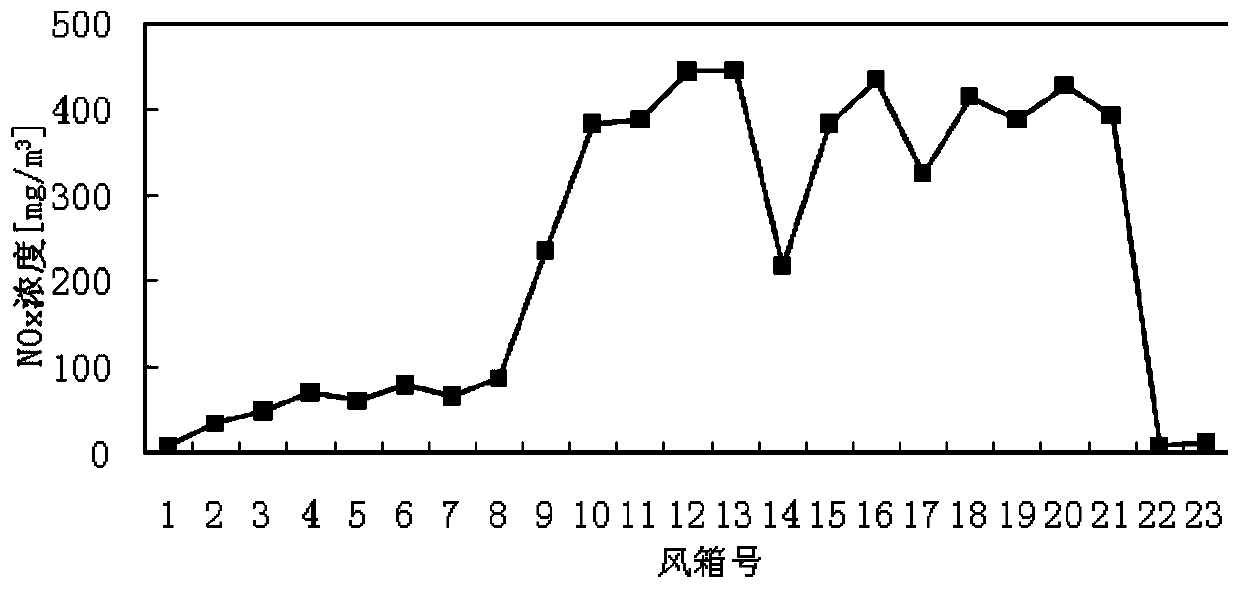

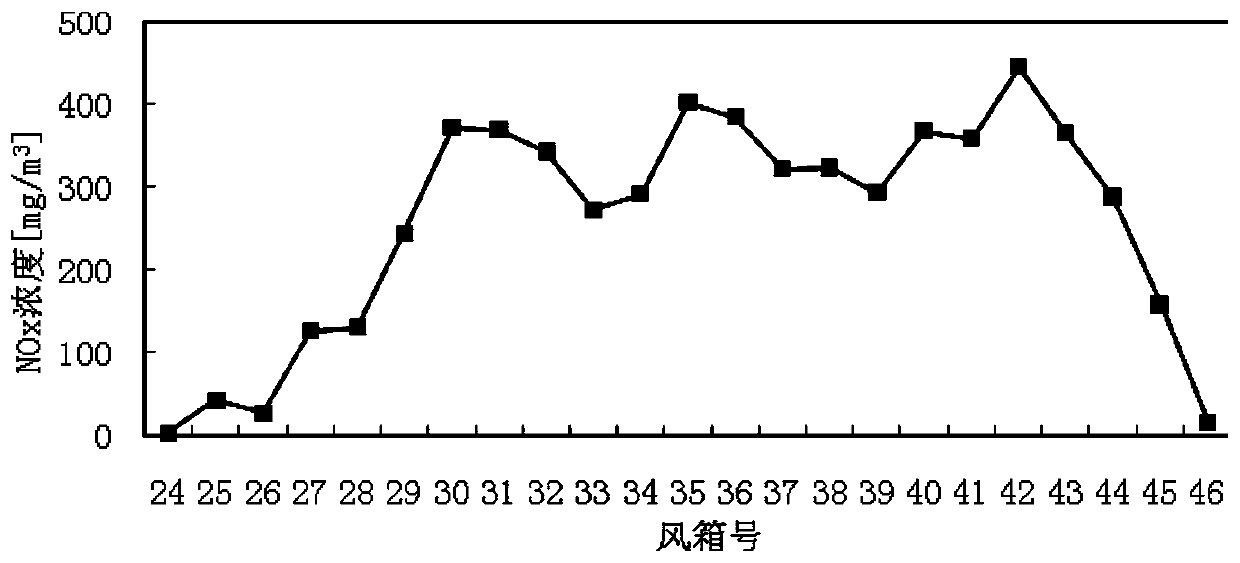

Sectional circulating soot catalytic denitration process for sintering flue gas

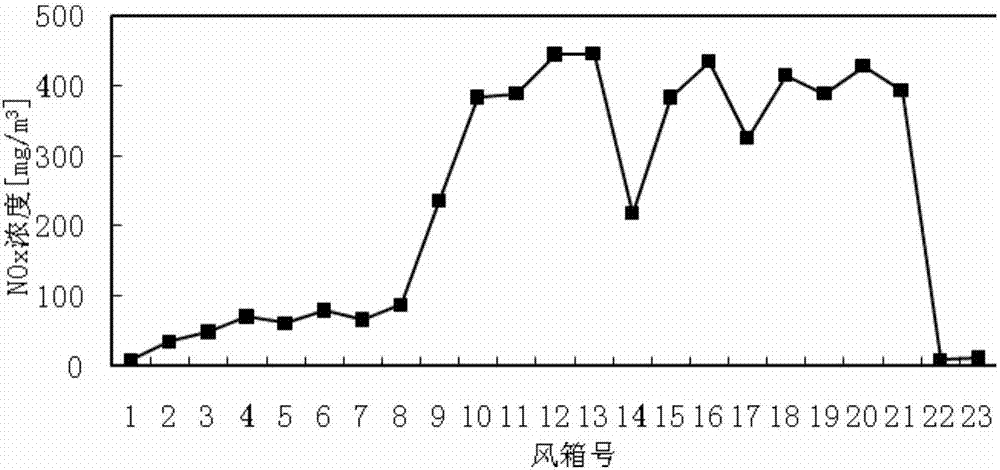

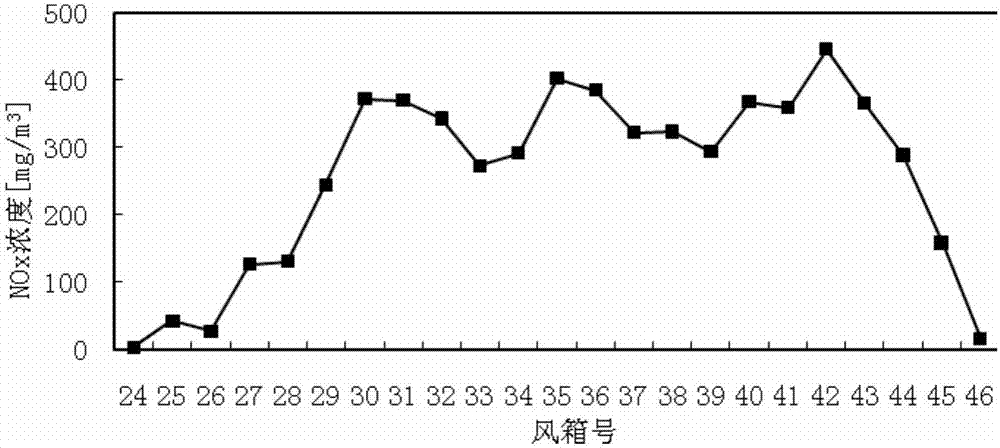

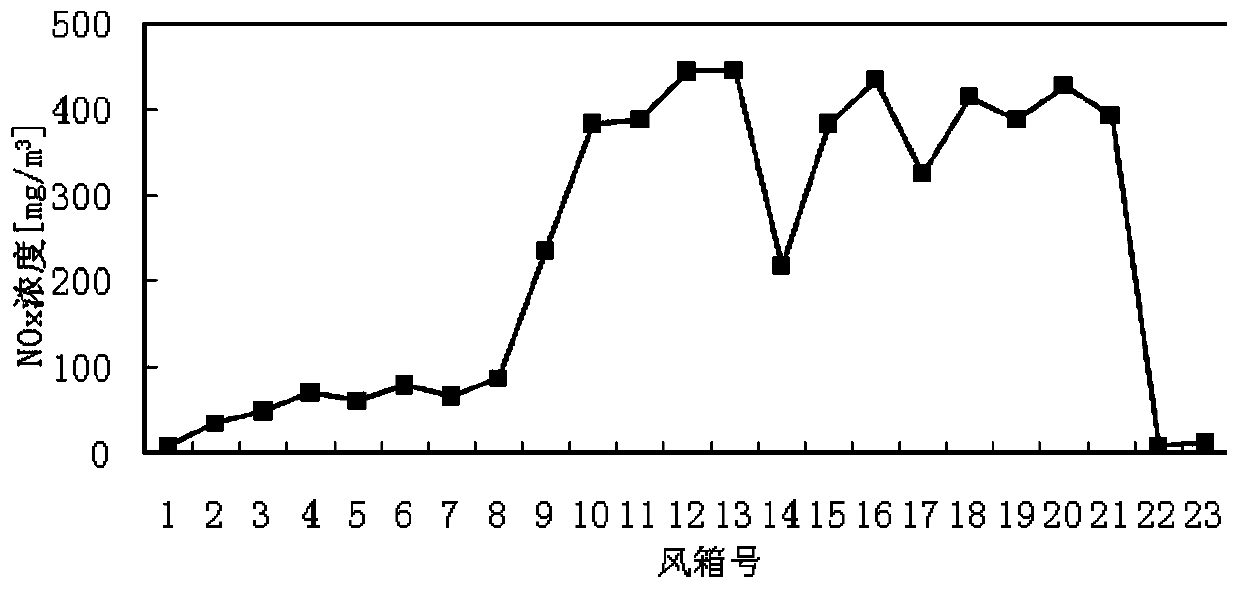

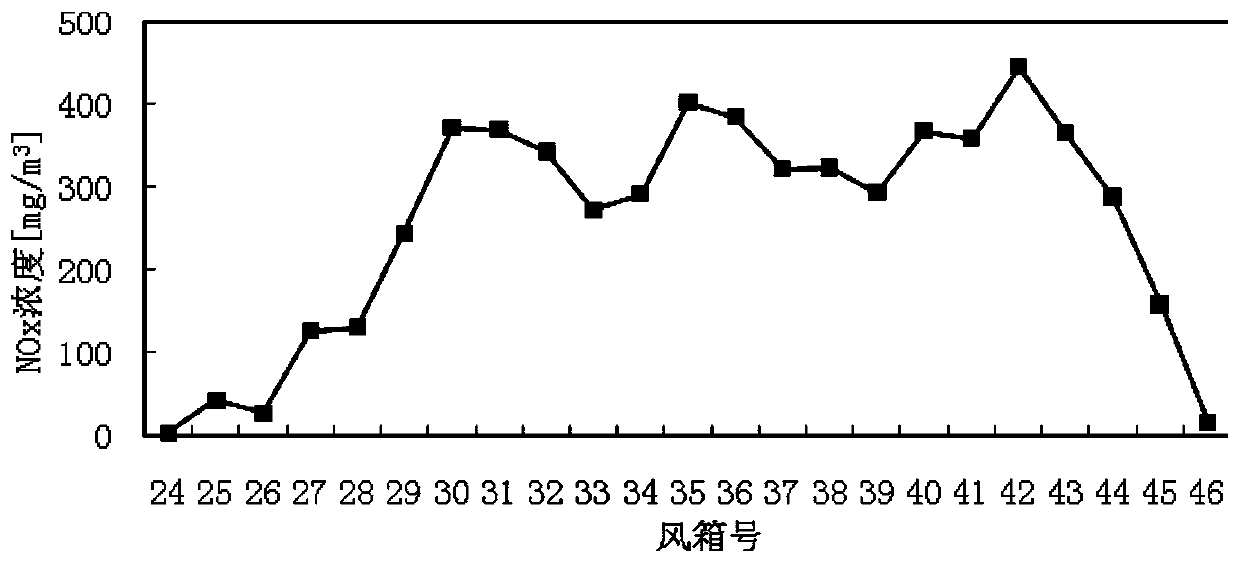

ActiveCN107413193ARealize online denitrificationLarge amount of dustGas treatmentDispersed particle separationFlue gasSmall footprint

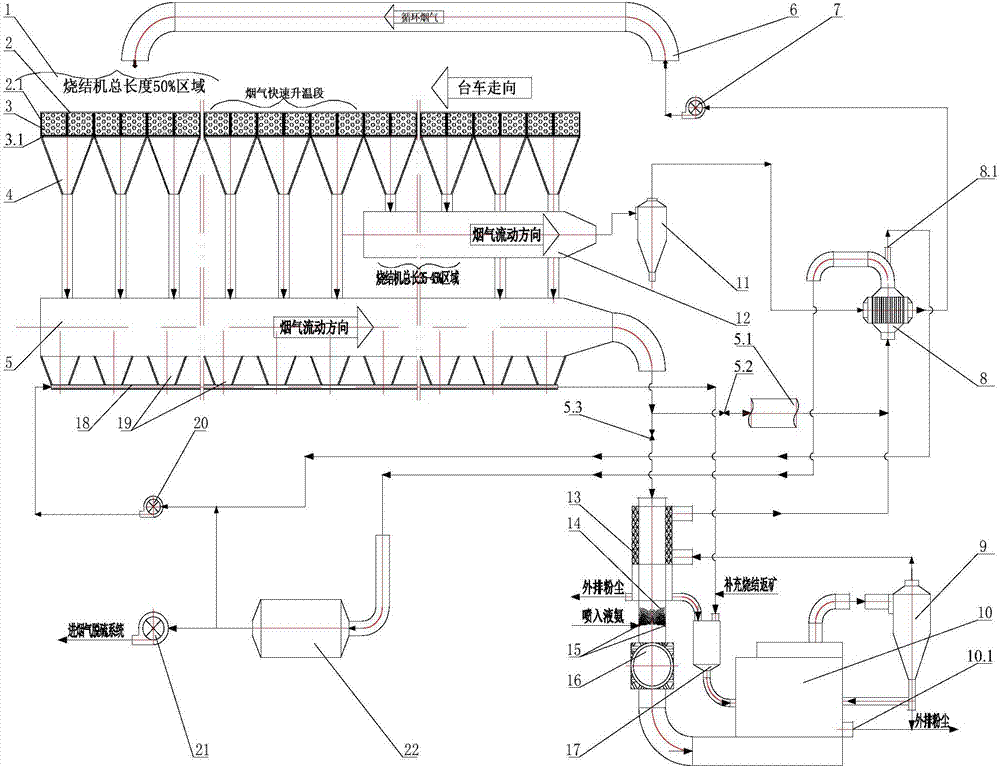

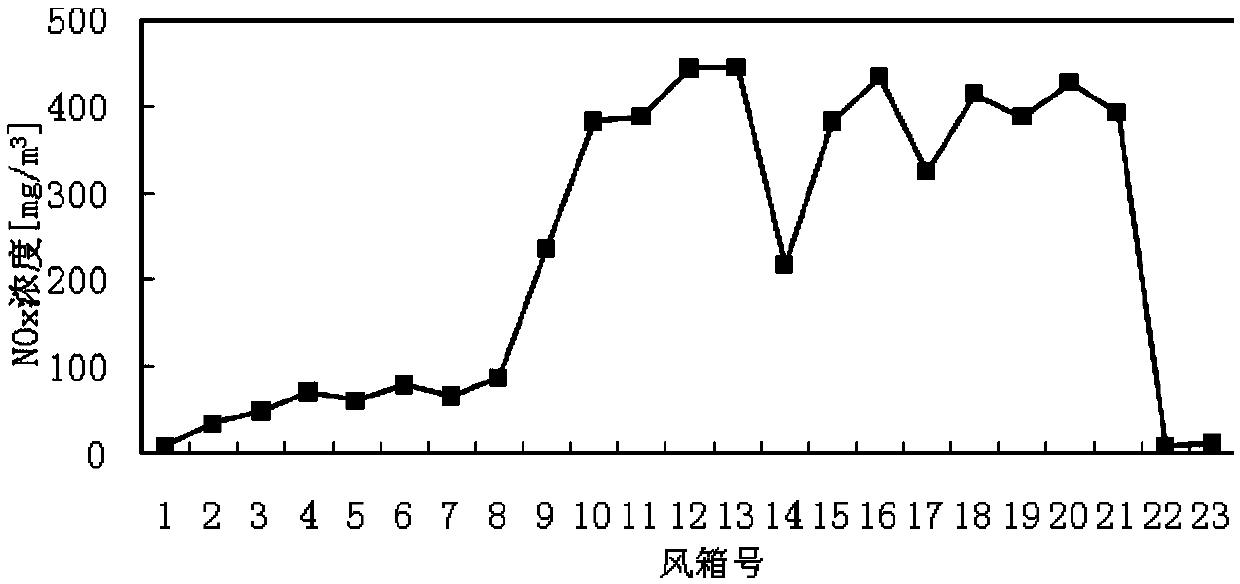

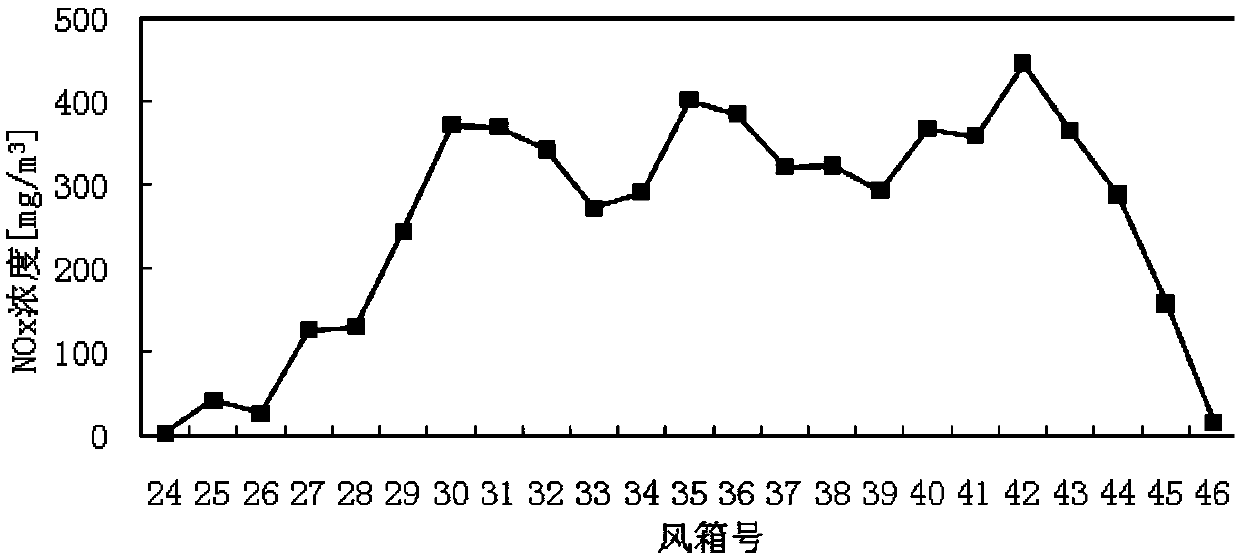

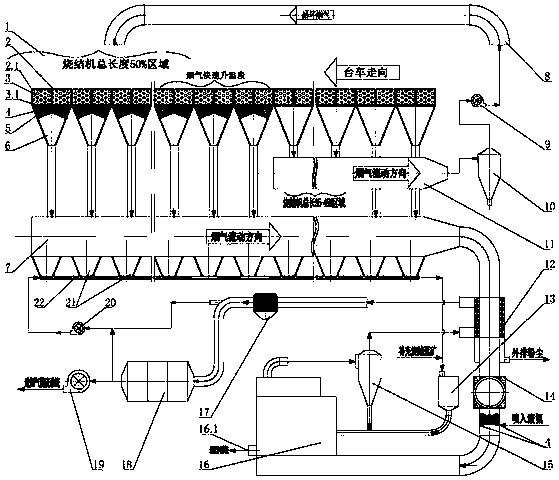

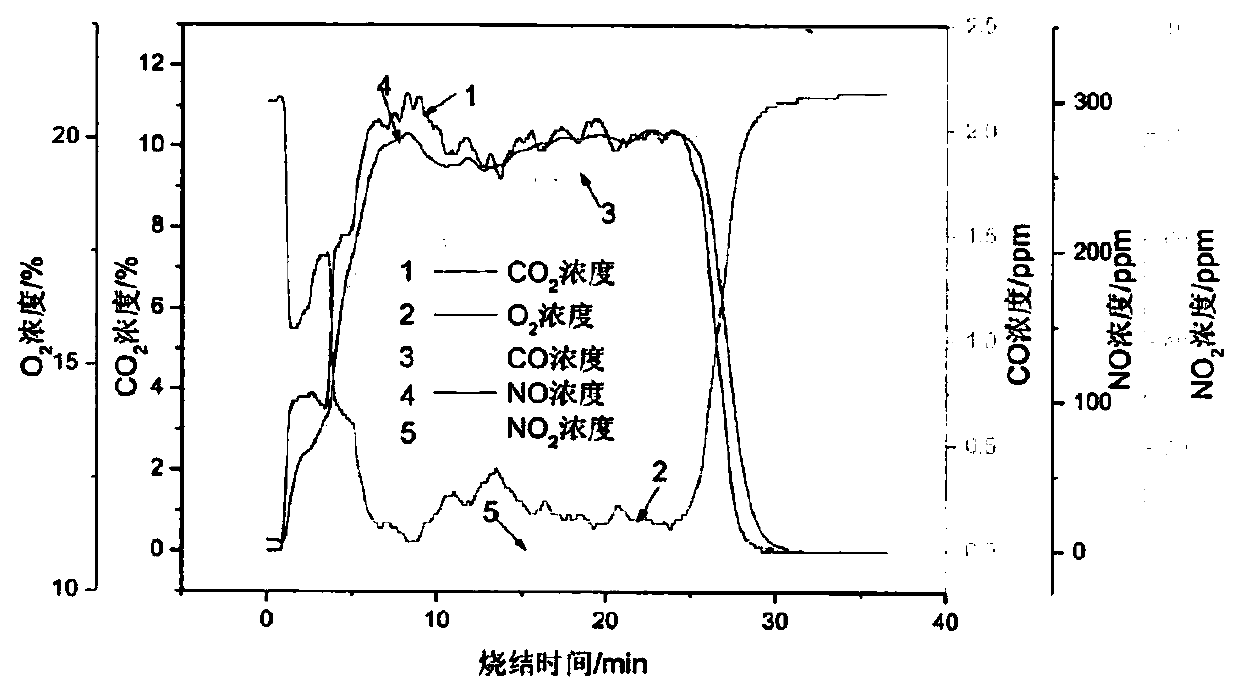

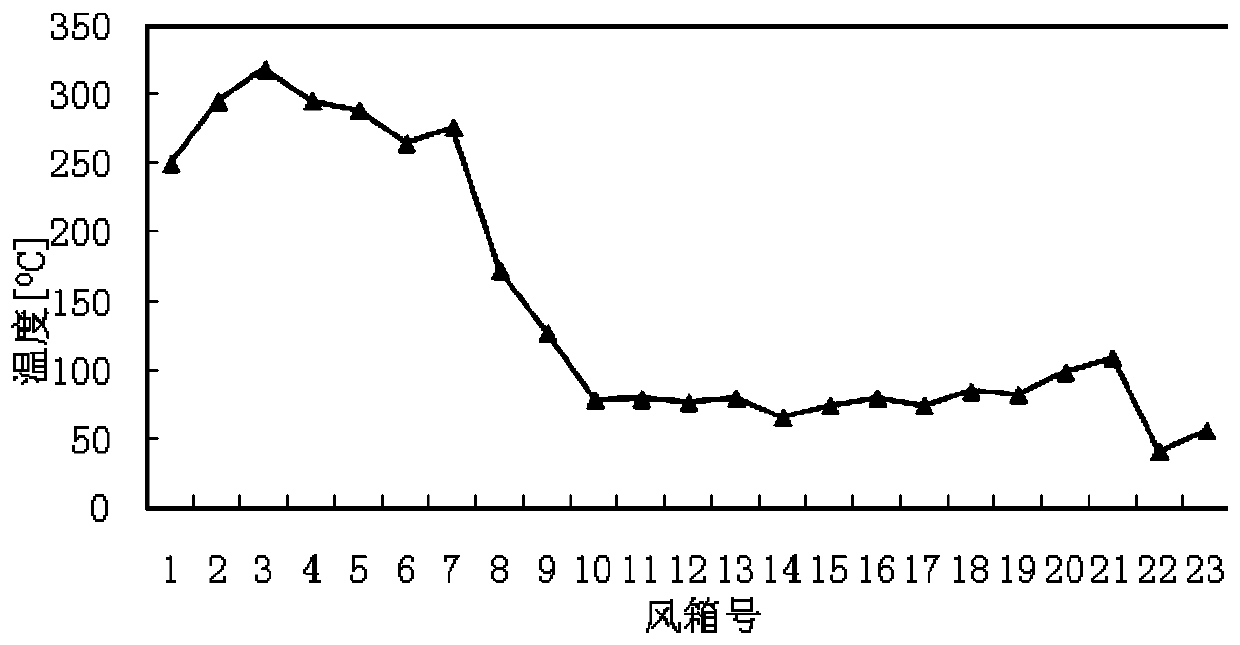

The invention relates to a sectional circulating soot catalytic denitration process for a sintering flue gas. According to the technical scheme, the process comprises the steps as follows: the sintering flue gas passes through a sintered material layer, a backing material, a bottom grate of a trolley of a sintering machine and an air bellow and enters a flue gas pipeline; the sintering machine is sequentially divided into an ignition segment, a machine head segment, a flue gas rapid heating segment and a machine tail segment along the advancing direction of the trolley; the flue gas pipeline comprises a main flue and a circulating flue gas main flue; the sintering flue gas collected by the machine tail segment, the flue gas rapid heating segment and the air bellow at the lower part of the ignition segment enters the main flue; and the sintering flue gas collected by the air bellow at the lower part of the machine head segment of the sintering machine enters the circulating flue gas main flue, is fed into a circulating flue gas hood at the upper part of the trolley at the machine tail segment and the flue gas rapid heating segment of the sintering machine after dust is removed through a circulating flue gas dust collector and then enters a sintered material layer again. The sectional circulating soot catalytic denitration process is simple in technological process; sintering soot autocatalytic denitration is achieved without outsourcing a denitration catalyst; and the sectional circulating soot catalytic denitration process is good in denitration effect, high in waste heat recovery rate, small in floor area, friendly to environment, low in denitration equipment investment and low in denitration operation cost.

Owner:武汉钢铁有限公司

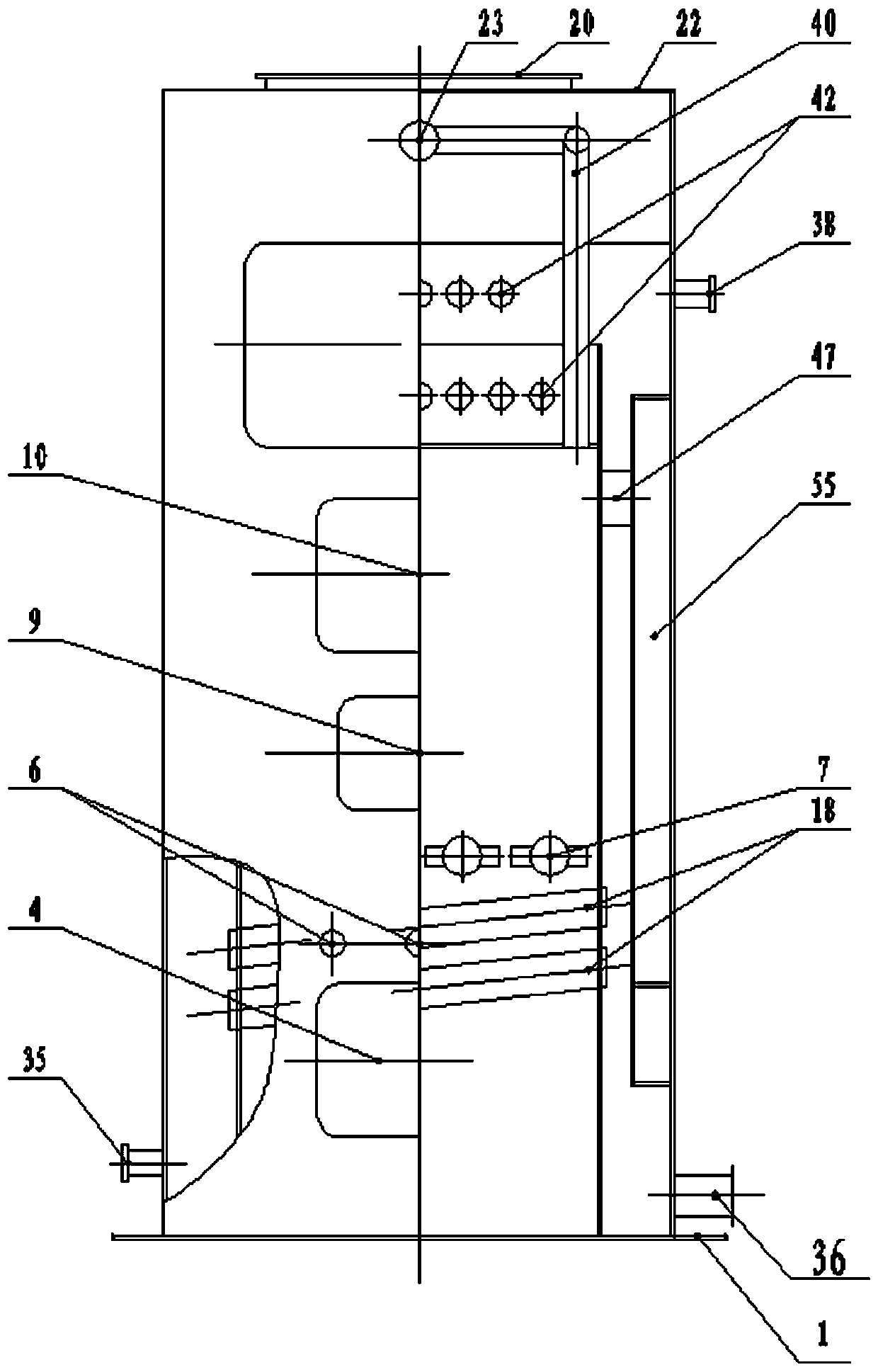

Sintering flue gas autocatalysis-based flue gas circulating denitrification system

ActiveCN107029554AImprove the environmentReduce dustGas treatmentDispersed particle separationAutocatalysisFlue gas

The invention relates to a sintering flue gas autocatalysis-based flue gas circulating denitrification system. According to the technical scheme, the system comprises a sintering machine, wherein an air box is arranged at the lower part of a trolley of the sintering machine; an outlet in the bottom of the air box communicates with a flue gas pipe; the sintering machine is sequentially divided into four areas, namely an ignition segment, a machine head segment, a flue gas quick heating segment and a machine tail segment along an advancing direction of the trolley; the outlet of a main flue powder hopper at the lower part of the flue gas pipe connected with the air box in the areas of the machine tail segment and the flue gas quick heating segment is connected with a dust pneumatic conveying pipe; and the outlet of the dust pneumatic conveying pipe is connected to a fluidized bed denitrification reactor through a particle material cabin. The system provided by the invention is simple, high in afterheat recovery rate, small in floor area, friendly to environment, economical in denitrification equipment investment and low in denitrification operation cost, and autocatalytic smoke denitrification is carried out without purchasing a denitrification catalyst.

Owner:武汉钢铁有限公司 +2

Sintering flue gas denitration technology based on sintering flue gas circulation and flue dust catalysis

ActiveCN107349783AImprove the environmentReduce dustGas treatmentDispersed particle separationSuction forceFlue gas

The invention relates to a sintering flue gas denitration technology based on sintering flue gas circulation and flue dust catalysis. According to the technology, sintering flue gas penetrates a sintered material layer, a basic material, a fine-toothed comb arranged on the bottom of the trolley of a sintering machine, and an air bellow under the trolley under the effect of the suction force of a high pressure draught fan and enters a flue gas pipeline. Along the moving direction of the trolley, the sintering machine is divided into four areas: an ignition section, a machine head section, a flue gas rapid temperature rising section, and a machine tail section. The particles in the sintering flue gas of the machine tail section and the flue gas rapid temperature rising section deposit in the air bellow and flue gas pipeline and then enter a main flue powder hopper. The particles in the main flue powder hopper is delivered to a particle material chamber through a dust pneumatic transmission pipe by pneumatic transmission and then delivered into a fluidized bed denitration reactor to carry out denitration catalysis. The technical process is simple, the dust catalytic denitration can be performed without any purchased denitration catalyst; the waste heat recovery rate is high, the occupied area is small, the technology is environmentally friendly, the denitration equipment investment is little, and the denitration operation cost is low.

Owner:WUHAN WUTUO TECH

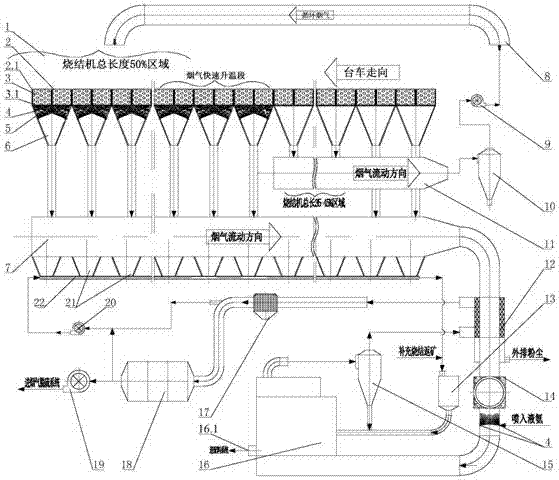

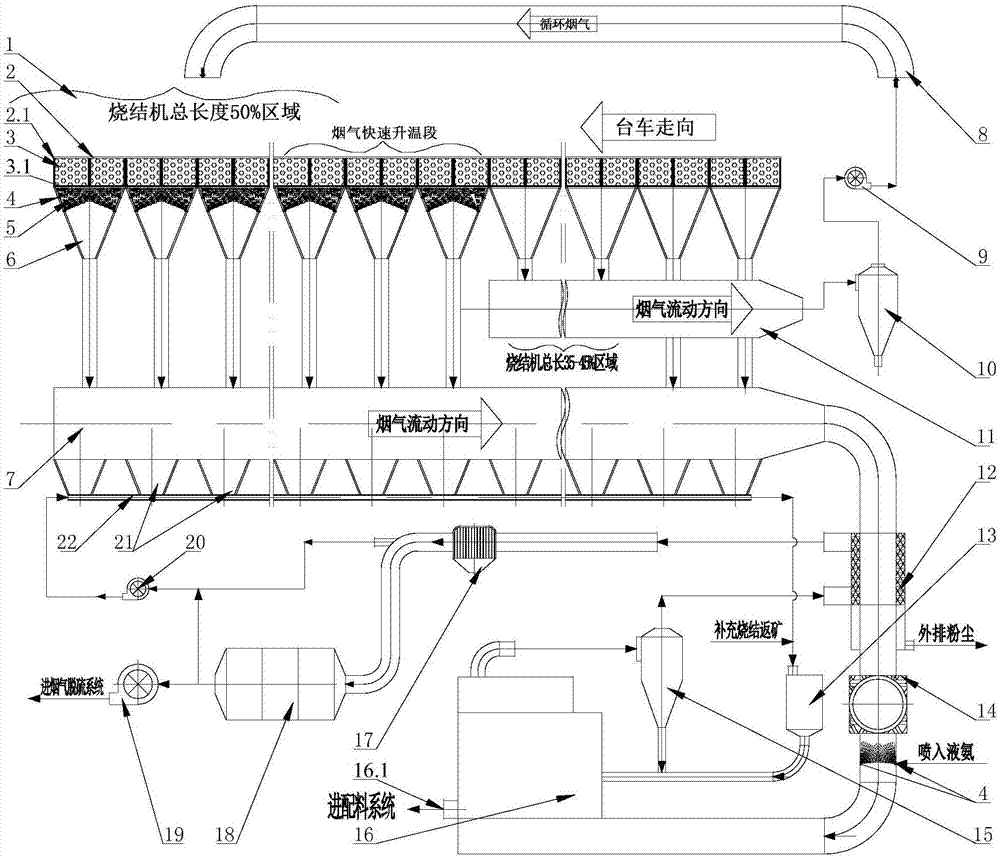

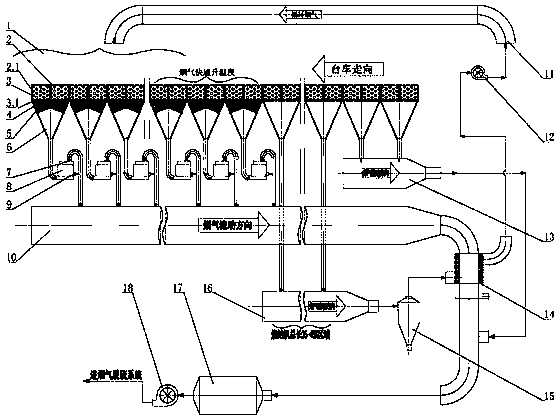

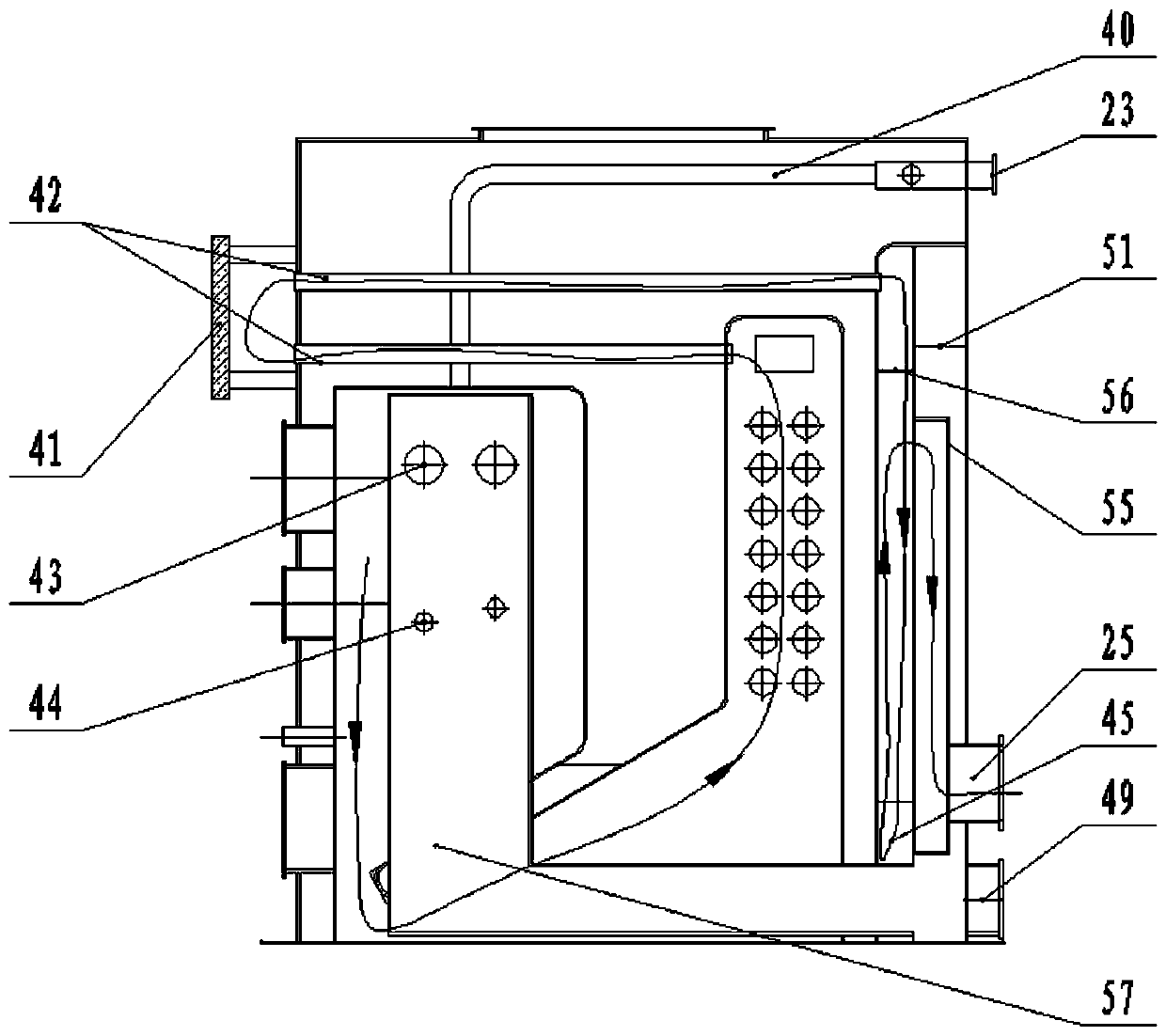

Sintering flue gas mass-divided directional circulation and on-line denitration system

ActiveCN107238297ARealize online denitrificationIncrease temperatureGas treatmentDispersed particle filtrationFlue gasFluidized bed

The invention relates to a sintering flue gas mass-divided directional circulation and on-line denitration system. According to the technical scheme, the sintering flue gas mass-divided directional circulation and on-line denitration system comprises a sintering machine. Air boxes are arranged below trolleys of the sintering machine, and bottom outlets of the air boxes communicate with a gas flue pipeline. The sintering machine is divided into an ignition section, a machine head section, a flue gas fast heating section and a machine tail section in sequence in the advancing direction of the trolleys. The gas flue pipeline comprises a high temperature flue gas main flue, a circulatory flue gas main flue and a machine head ignition section flue. The outlets of the air boxes below the machine tail section and the flue gas fast heating section communicate with the high temperature flue gas main flue through fluidized bed reactors separately, the outlets of the air boxes below the machine head section communicate with a circulatory flue gas cover on the trolleys of the sintering machine through the circulatory flue gas main flue, and the outlets of the air boxes below the ignition section are connected with the machine head ignition section flue. The sintering flue gas mass-divided directional circulation and on-line denitration system is simple, compact in structure, high in waste heat recovery rate and low in denitration operation cost, denitration equipment investment is saved, and zero input of denitration catalysts and flue gas heating energy consumption is achieved.

Owner:WUHAN UNIV OF SCI & TECH +1

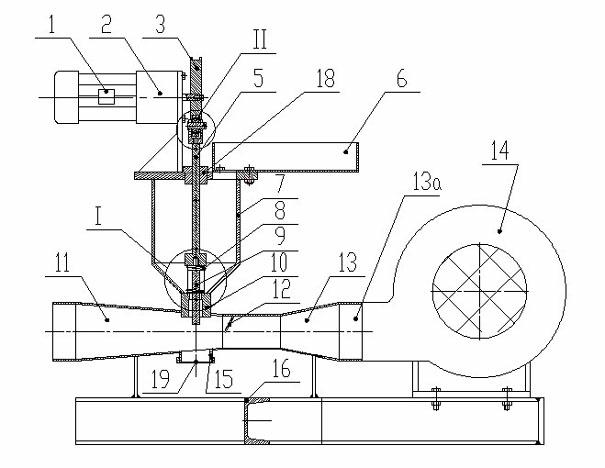

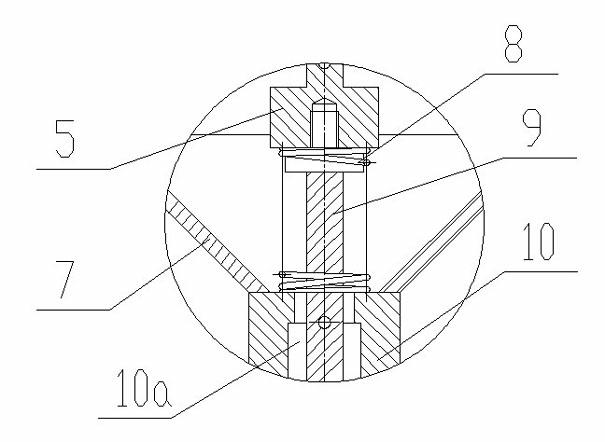

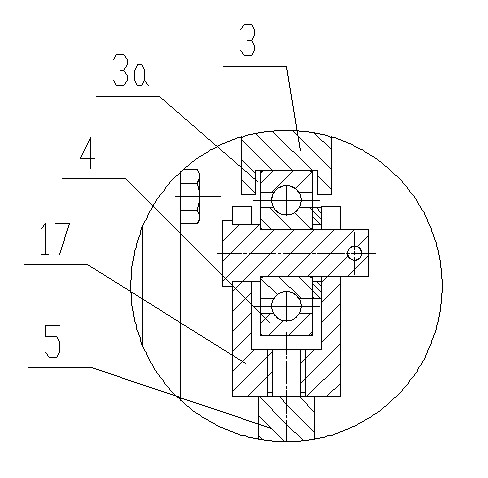

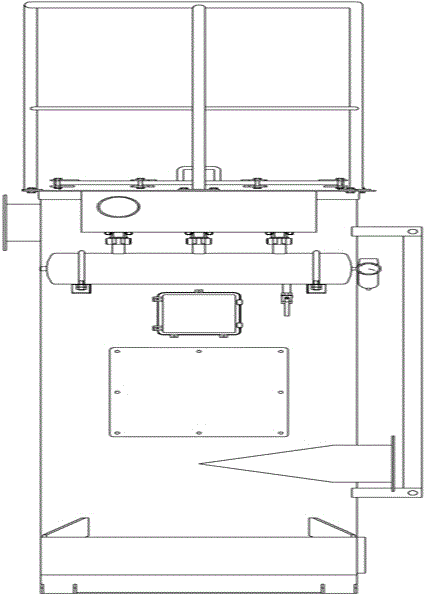

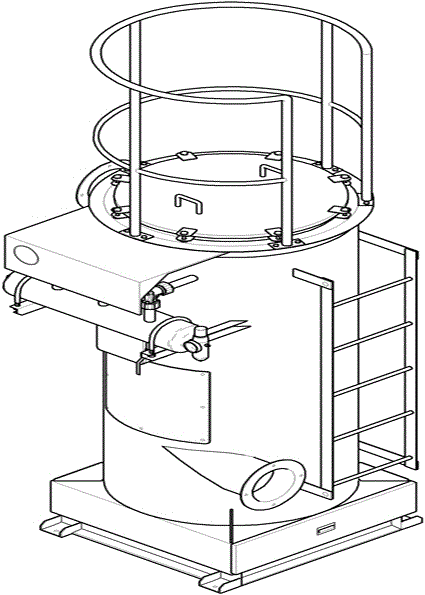

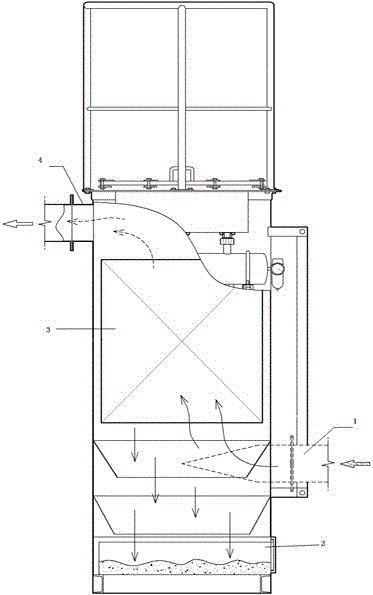

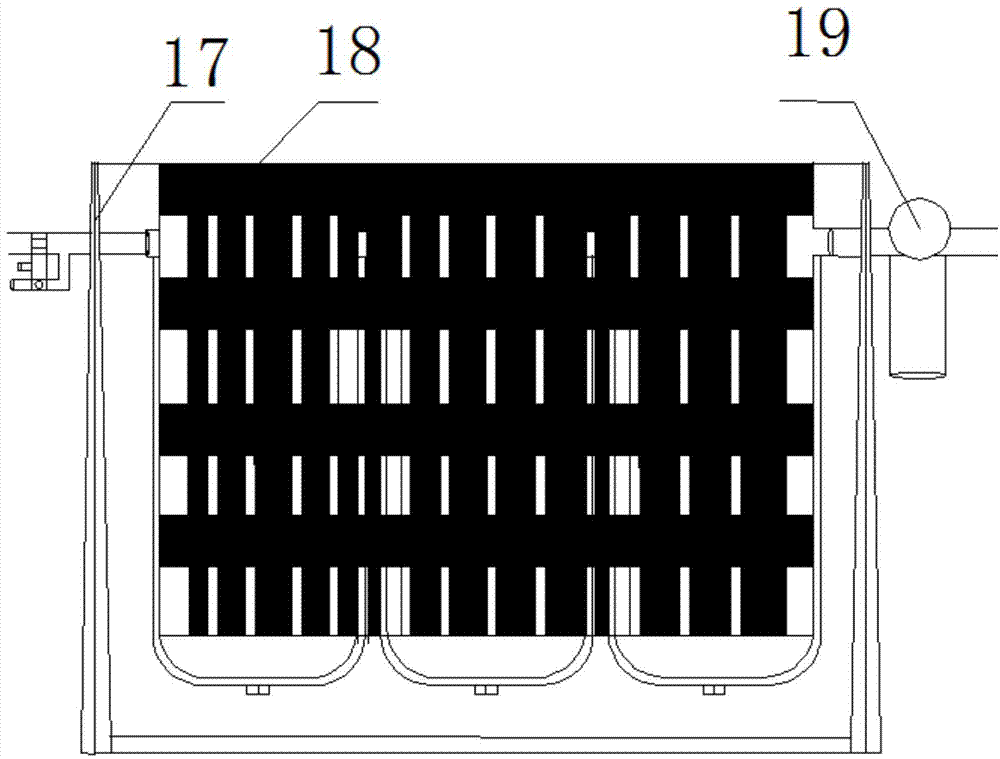

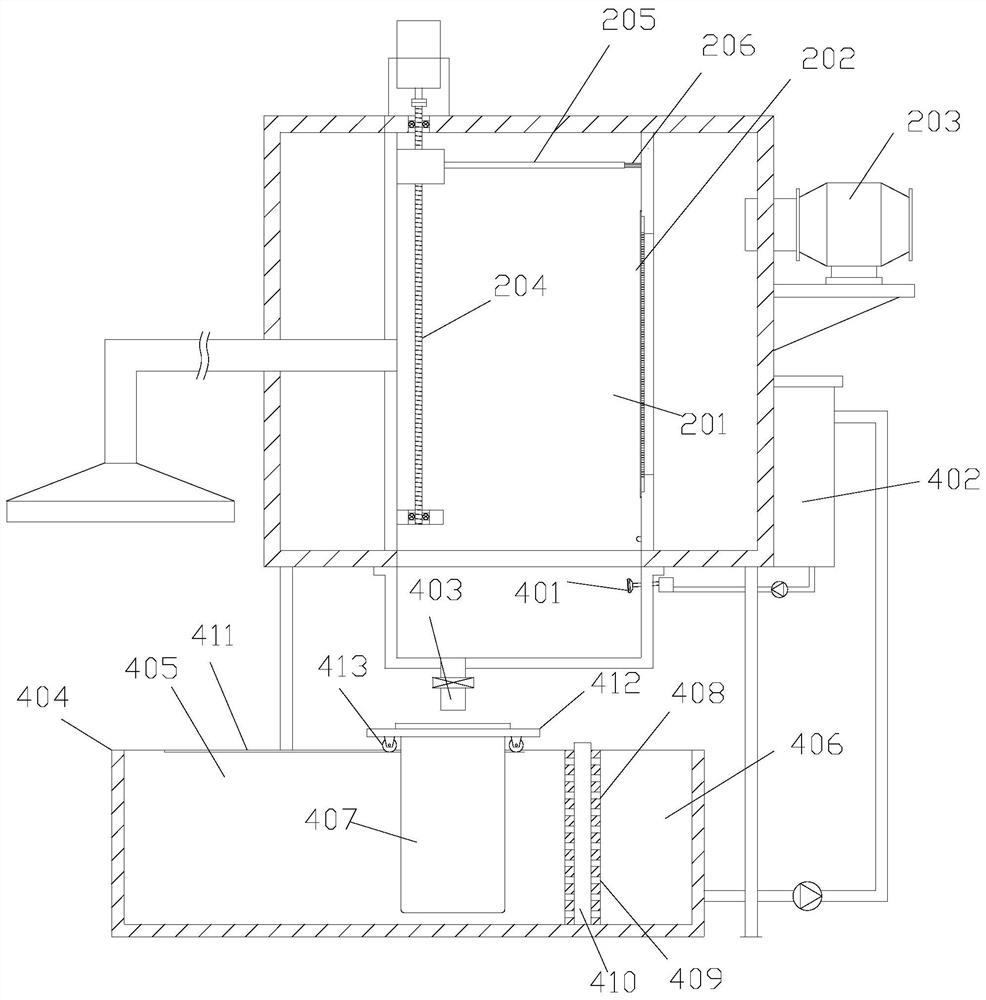

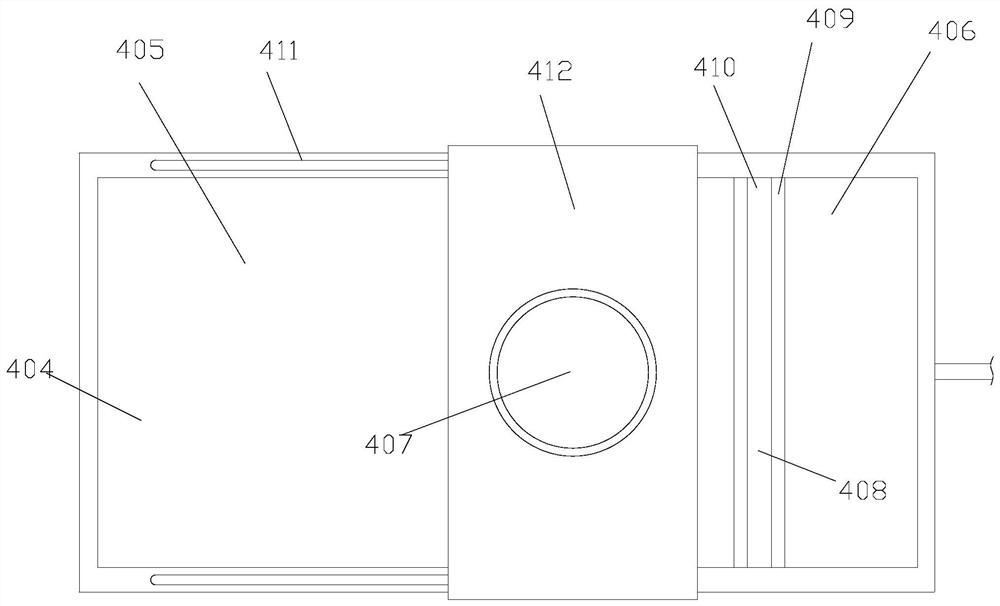

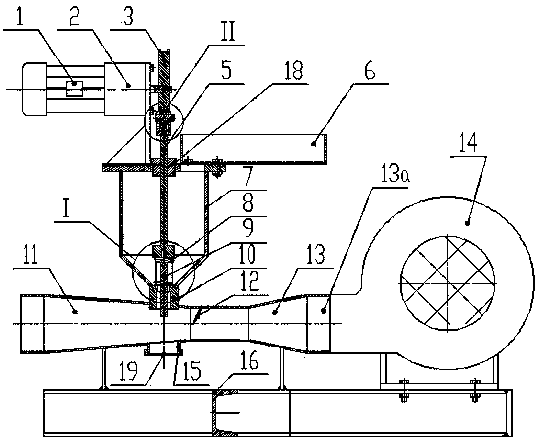

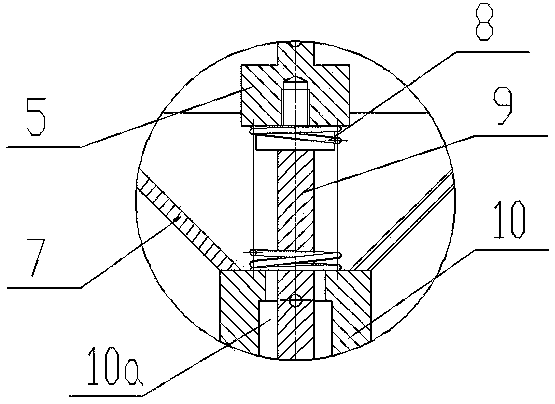

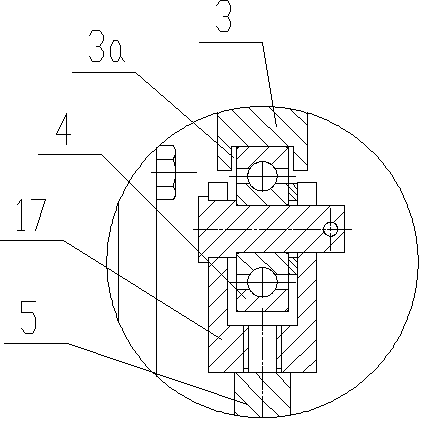

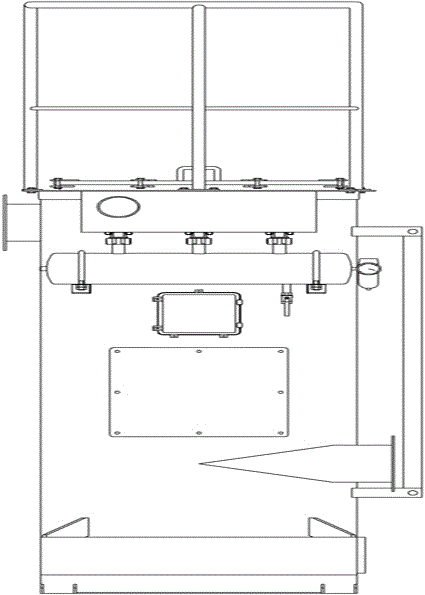

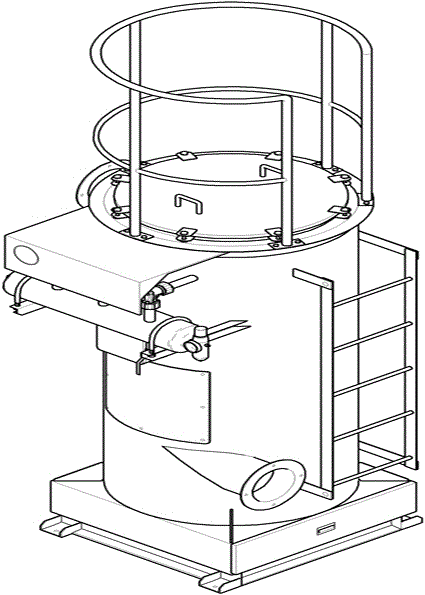

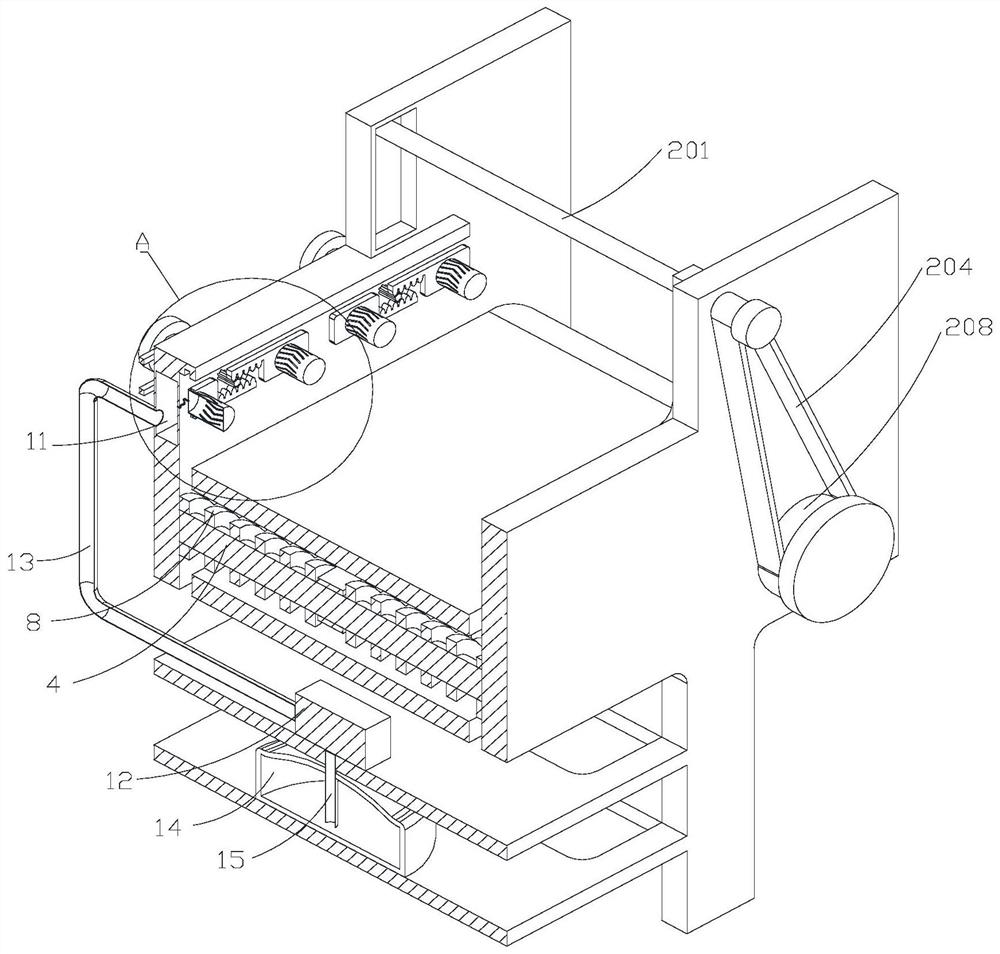

Reciprocating material feeding type high-concentration dust producer

ActiveCN102680266AScientific and reasonable inspection and detection of dust suppression efficiencyAffect performance detectionStructural/machines measurementParticle suspension analysisHigh concentrationReciprocating motion

The invention discloses a reciprocating material feeding type high-concentration dust producer which comprises a launching barrel and an air drafting baffle. The launching barrel and the air drafting baffle are connected with a rack fixedly; a shaft sleeve is arranged above the launching barrel along the radial direction; a dust producing rod is arranged in the shaft sleeve; the diameter of the dust producing rod is smaller than the aperture of the inner hole of the shaft sleeve; a reciprocating motion rod is fixedly connected at the upper end of the dust producing rod; a dust depositing tank is arranged above the shaft sleeve; the upper end of the reciprocating motion rod penetrates through the dust depositing tank; the lower end of the reciprocating motion rod is located in the dust depositing tank; the dust depositing tank is communicated with the launching barrel through the shaft sleeve; a bearing installation base is fixed at the upper end of the reciprocating motion rod; a rolling bearing is arranged in the bearing installation base; the rolling bearing is in rolling contact with an eccentric wheel; the eccentric wheel is connected with a speed change device; the speed change device is connected with a motor; a spring is arranged between the reciprocating motion rod and the shaft sleeve; and the air drafting barrel is provided with an original dust gauge opening under the shaft sleeve. The dust producer is in a manner of reciprocating material feeding with large dust production quantity, high dust production concentration and small dust production error.

Owner:CHINA COAL TECH ENG GRP CHONGQING RES INST

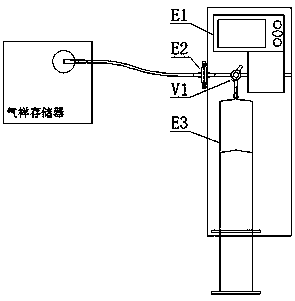

Device for collecting trace dust in gas and method for detecting particle diameter and content of particles

PendingCN107907388ASampling method is simpleFlexible sampling methodWithdrawing sample devicesParticle size analysisAnalytical chemistryPhysics

The invention discloses a device for collecting trace dust in gas and a method for detecting the particle diameter and the content of particles. The device comprises a dust filter, a three-way valve,a gas volume flow rate meter and an injector, wherein the dust filter is connected with the gas volume flow meter and the injector through the three-way valve. The invention also discloses the methodfor collecting and detecting the particle diameter and the content of particles of the trace dust in the sample gas. The device and the method can be applicable to the conditions that the sample gas quantity is less than 100mL and the dust content is less than 5mg / L, and can also be applicable to the conditions that the gas quantity is greater than or equal to 100mL and the dust content is greaterthan or equal to 5mg / L; the problem that the detection of the trace dust in the gas is limited by the sample quantity and the dust content is solved.

Owner:SOUTH CHINA UNIV OF TECH

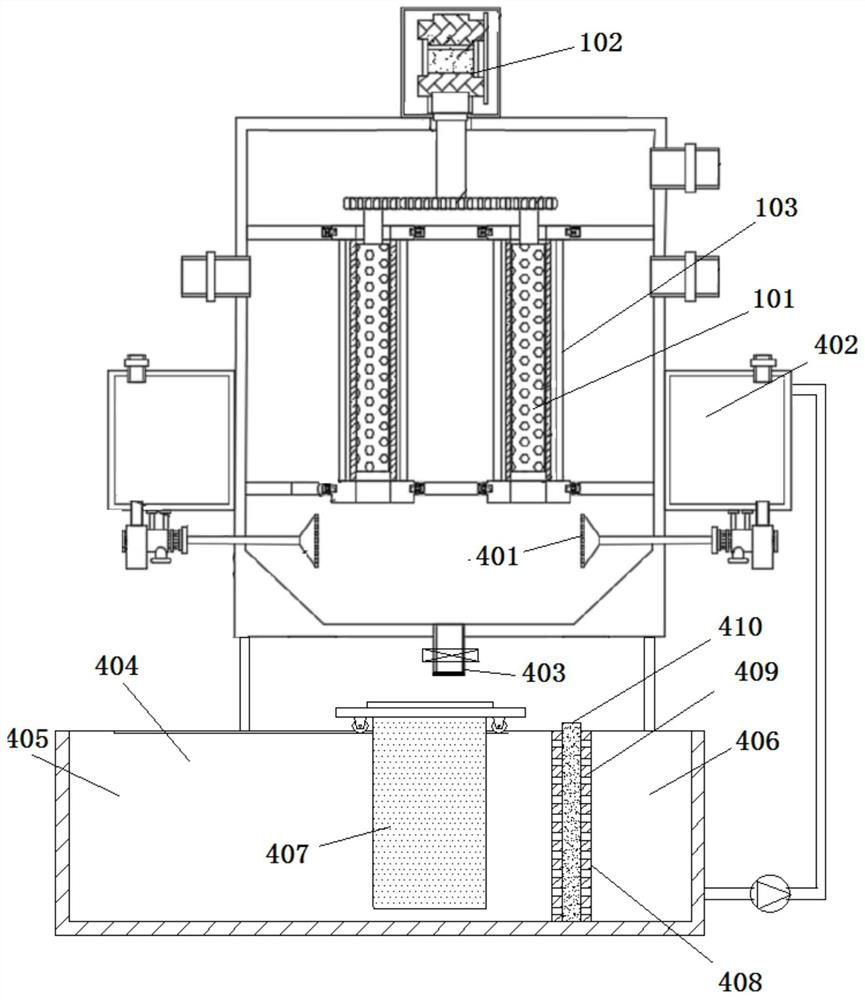

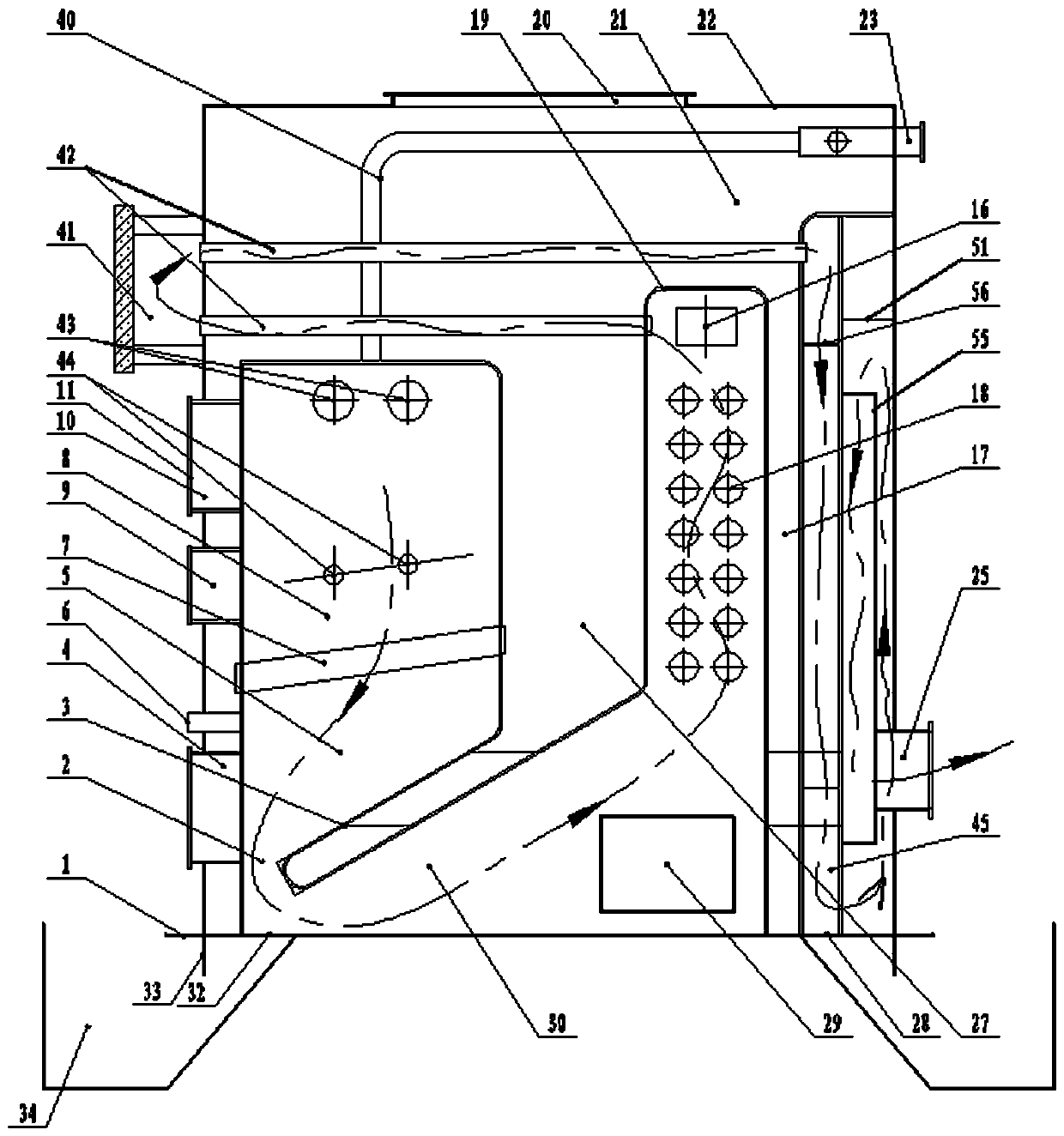

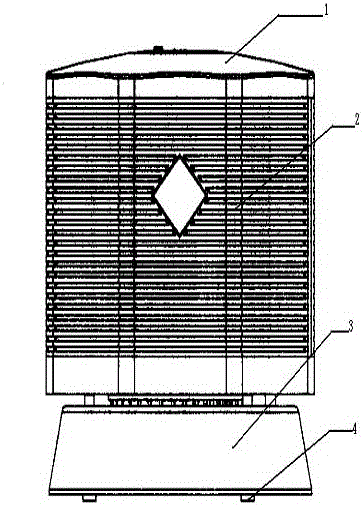

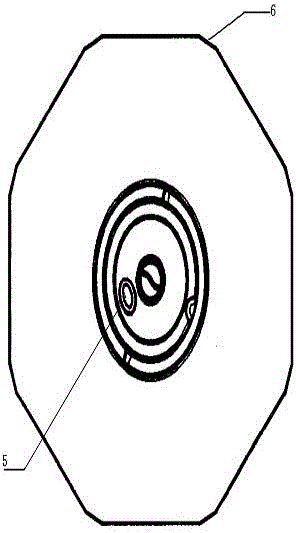

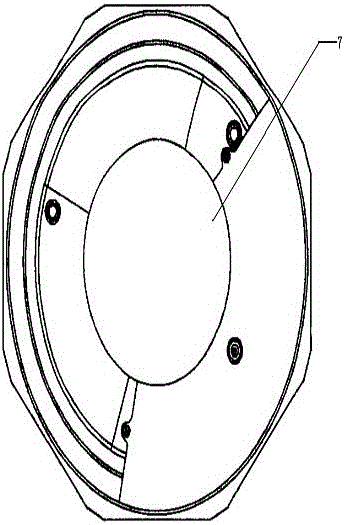

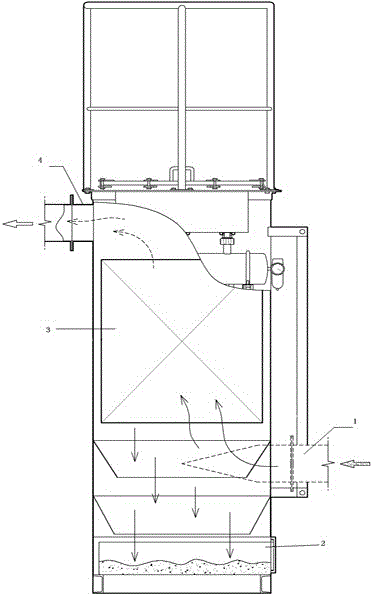

Large-size efficient air purification equipment for public place

ActiveCN105879565AComprehensive adsorptionGood effectGas treatmentOther chemical processesParticulatesNano structuring

The invention provides large-size efficient air purification equipment for a public place. The large-size efficient air purification equipment comprises an air inlet with a flange, an air outlet, provided with a flange, of a connection short pipe, a shell and a draught fan located in the shell, a particle adsorption device and a pressurizing device, and a base, and further comprises a washing device of the particle adsorption device and an anaerobic acidulation degradation device located at the bottom of the shell, wherein the washing device is located at the top of the shell; one end of the air outlet of the connection short pipe is further connected with an air-liquid separator; the particle adsorption device comprises a cavity; a titanium pipe is arranged inside the cavity; the surface of the titanium pipe is of a honeycomb-shaped titanium dioxide nano structure; the titanium pipe forms a bent loop structure in the cavity; the diameter of the titanium pipe is 3mm-10mm; and the large-size efficient air purification equipment has a good pressure-bearing capability, a strong PM2.5 (Particulate Matter 2.5) adsorption capability, large dust accumulation and long service life, and can also realize degradation washing of the titanium pipe.

Owner:中环清新人工环境工程技术(北京)有限责任公司

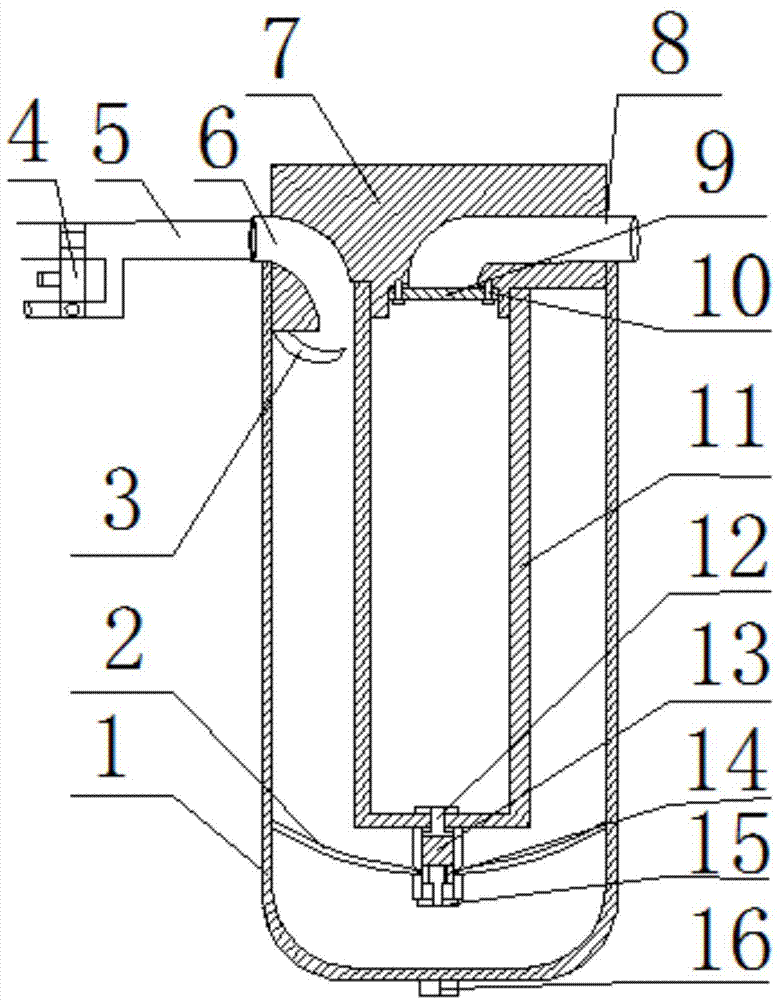

Gas filter applicable to float type pneumatic measuring instrument

InactiveCN103933791AProtect interestsIncreased design featuresDispersed particle filtrationWater storageWater discharge

The invention discloses a gas filter applicable to a float type pneumatic measuring instrument. The gas filter comprises a gas filter shell, a water guide plate, a flow guide plate, a multifunctional switch, a gas pipe, a gas source input joint, a gas filter shell cover, a gas source output joint, a filtration plate, a bolt, a filter element, an upper hollow bolt, a sliding block, a spring, a lower hollow bolt, a water discharging bolt, a bracket, an anti-explosion plate and a pressure gage. The gas filter is characterized in that the multifunctional switch is arranged; when the multifunctional switch is in one position, gas enters the gas filter through the switch; after the multifunctional switch is rotated by 180 degrees, the gas filter is connected with the atmosphere, the water flows into a water storage chamber from the gas filter; the gas is filtered for three times in the gas filter through crude, middle and high filtration cups of the filter element and the filtration plate; the anti-explosion plate is capable of effectively avoiding the harm to the human body and equipment when accidents happen; and three filters which are connected in series can guarantee the quality of the filtered air.

Owner:山东国运量仪精密机械有限公司

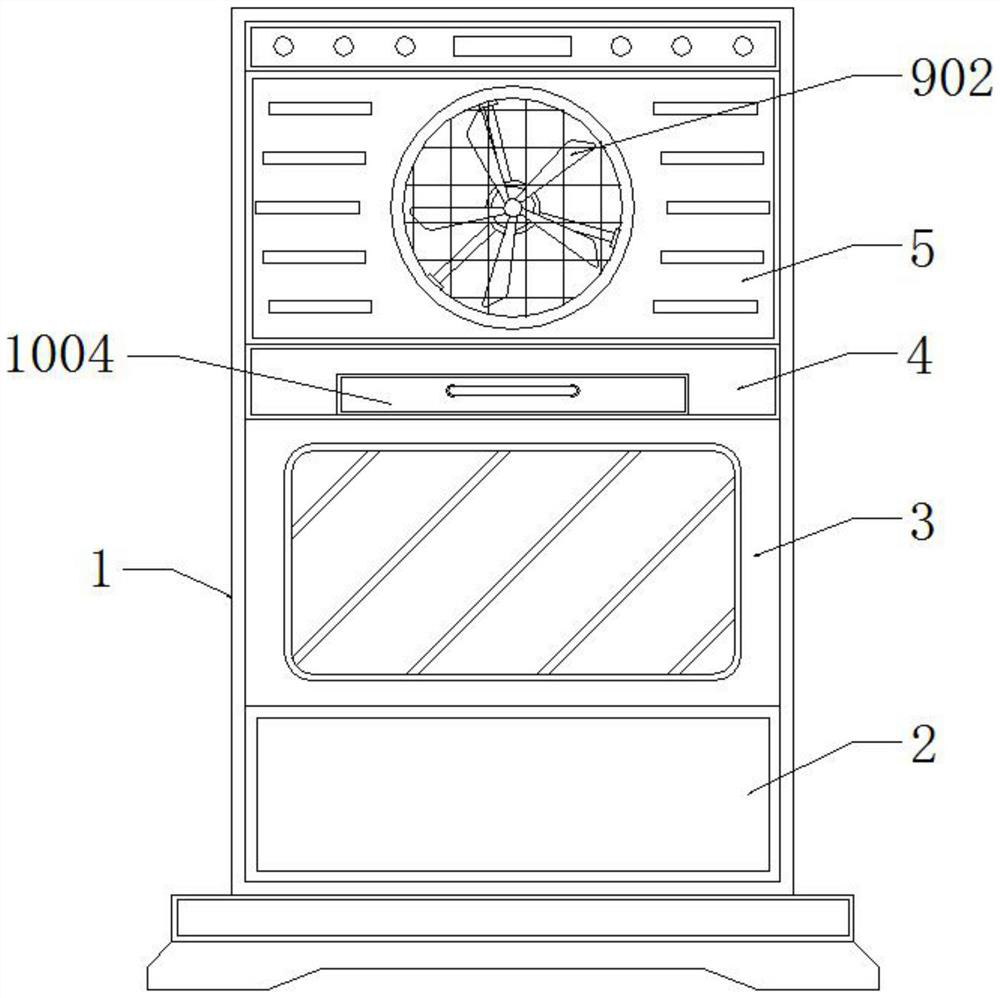

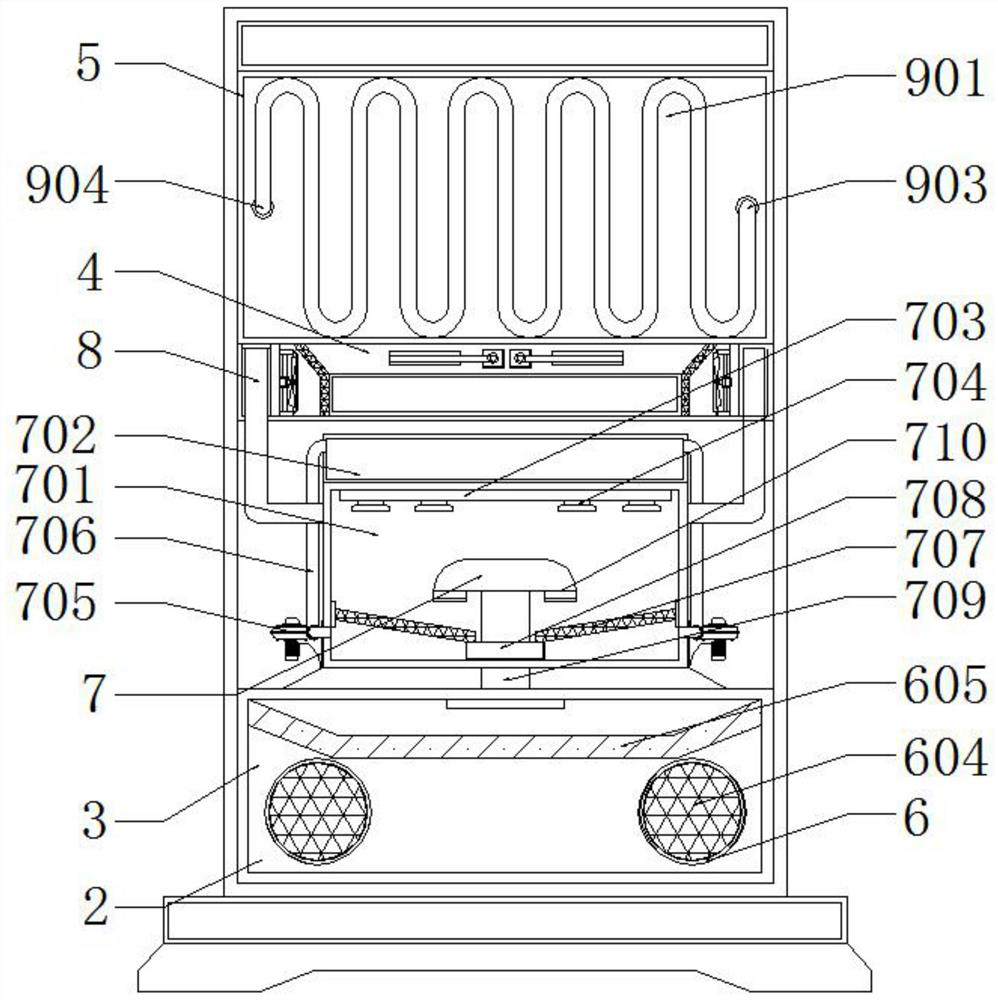

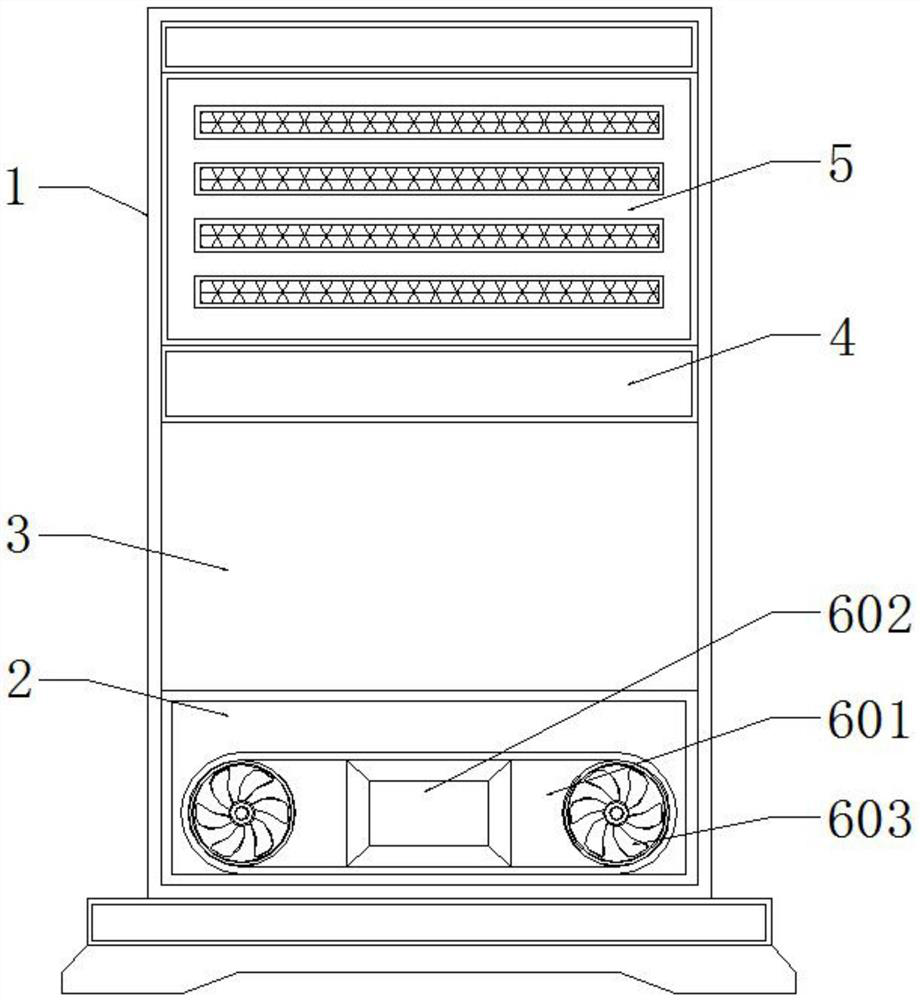

Water-cooling heat pump circulation indoor refrigeration central system

InactiveCN114165857AExchangeQuality improvementMechanical apparatusLighting and heating apparatusEngineeringAir exchange

The invention discloses a water-cooling heat pump circulation indoor refrigeration central system, and relates to the technical field of refrigeration central systems, the water-cooling heat pump circulation indoor refrigeration central system comprises an outer shell, a filtering and dust falling assembly and a water-cooling heat pump assembly, an air inlet box, a filtering box, a dust collecting box and a heat pump box are sequentially arranged in the outer shell from bottom to top, and the filtering and dust falling assembly is installed in the filtering box; the water-cooling heat pump assembly is arranged in the heat pump box and comprises an evaporator, an air outlet blower, a cold water drainage pipe, a hot water drainage pipe and a condenser, the air outlet blower is installed on the outer side of the front portion of the evaporator, and the condenser is installed behind the evaporator through the cold water drainage pipe and the hot water drainage pipe. According to the water-cooling heat pump circulation indoor refrigeration central system, air can be filtered and subjected to dust falling, indoor and outdoor air exchange is achieved, the quality of indoor refrigeration air is better, dust removal can be conducted on fan blades of the fan, and the situation that dust is accumulated on the surfaces of the fan blades, and consequently the dust content of an air outlet is large during use is avoided.

Owner:杭州中创科兴科技有限公司

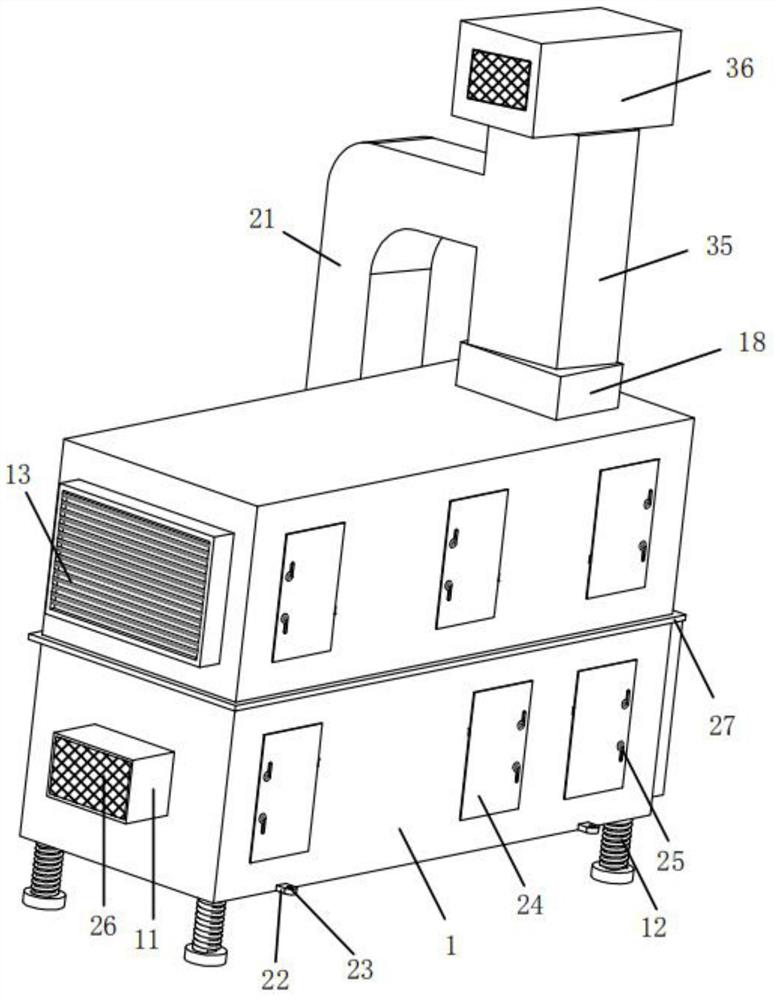

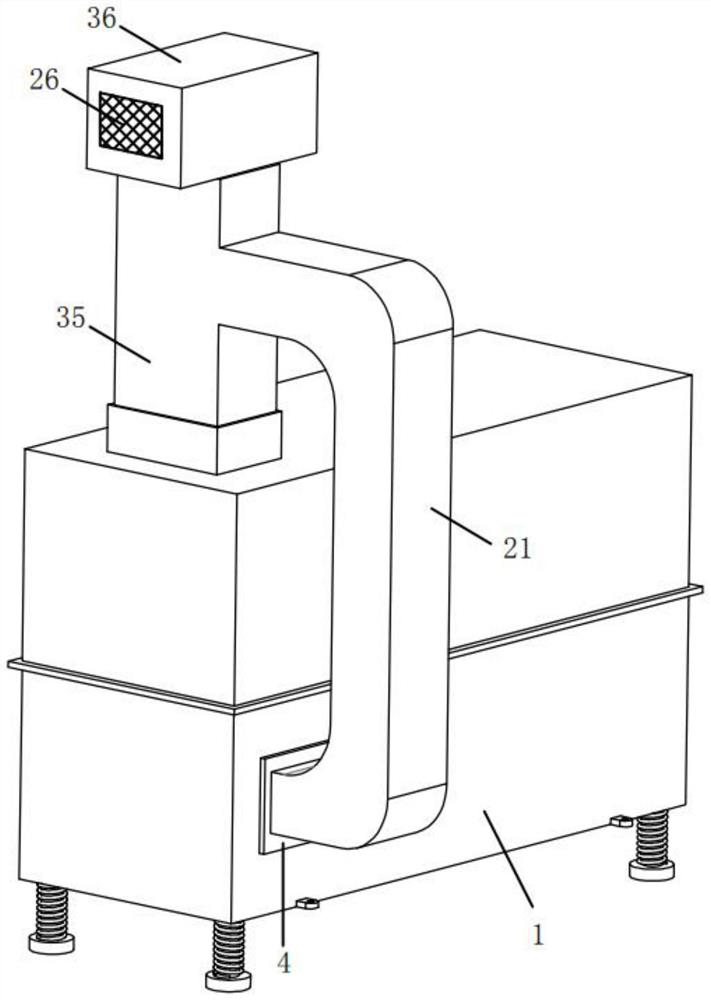

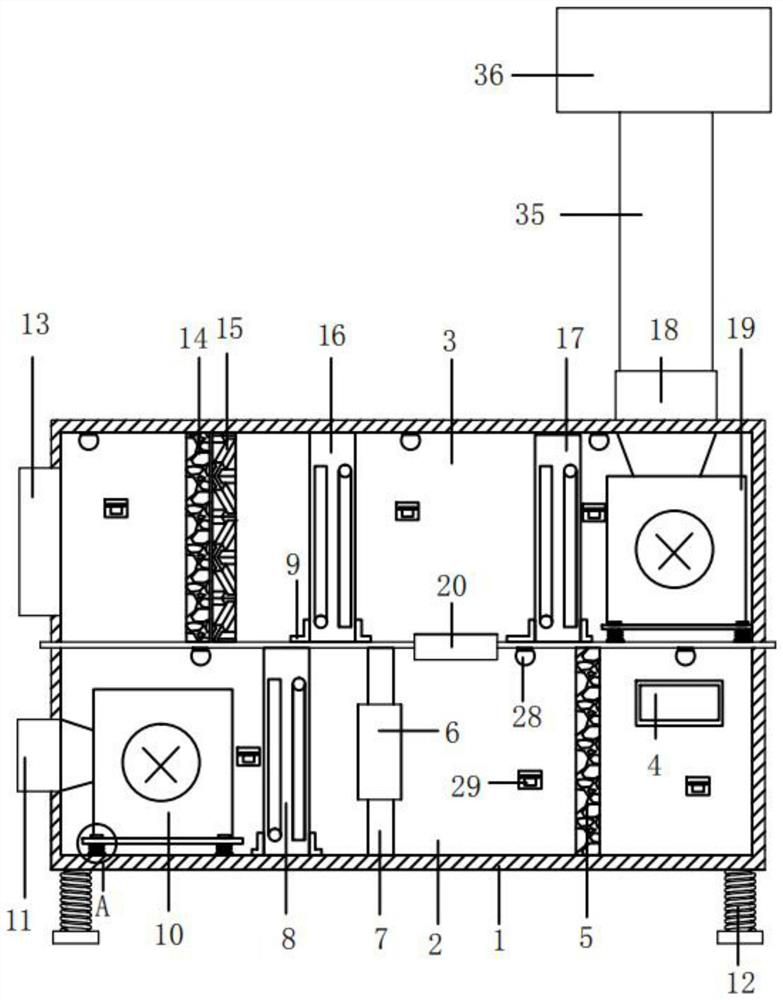

Combined heat recovery air conditioning unit

PendingCN112503634ALightweight panel structureReduce initial resistanceEnergy recovery in ventilation and heatingDucting arrangementsSurface coolingFresh air

The invention provides a combined heat recovery air conditioning unit, and belongs to the technical field of air conditioners. The combined heat recovery air conditioning unit comprises a mounting box, a first layer cavity and a second layer cavity are formed in the mounting box, an exhaust air outlet and a second electric air valve are arranged at the left end of the mounting box, and an exhaustair inlet is formed in the rear end of the mounting box. A fresh air outlet is formed in the upper end of the mounting box, an exhaust pipe is connected to the upper end of the fresh air outlet, an exhaust cylinder is arranged at the upper end of the exhaust pipe, a galvanized plate air return pipe is arranged at the rear end of the exhaust pipe, and the other end of the galvanized plate air return pipe is connected with the exhaust air inlet. An exhaust fan, a first surface cooling water retaining section, a first electric air valve and a first plate type G filter are sequentially arranged inthe first layer cavity from left to right. By means of the combined heat recovery air conditioning unit, fresh air energy consumption can be reduced, meanwhile, the air conditioner load is reduced, and therefore the operation cost of air conditioning equipment is reduced, exhaust air and fresh air are combined, and cross contamination is avoided.

Owner:上海永大菌业有限公司

Sintering flue gas separation and directional circulation and online denitrification system

ActiveCN107238297BRealize online denitrificationIncrease temperatureGas treatmentDispersed particle filtrationFluidized bedFlue gas

The invention relates to a sintering flue gas mass-divided directional circulation and on-line denitration system. According to the technical scheme, the sintering flue gas mass-divided directional circulation and on-line denitration system comprises a sintering machine. Air boxes are arranged below trolleys of the sintering machine, and bottom outlets of the air boxes communicate with a gas flue pipeline. The sintering machine is divided into an ignition section, a machine head section, a flue gas fast heating section and a machine tail section in sequence in the advancing direction of the trolleys. The gas flue pipeline comprises a high temperature flue gas main flue, a circulatory flue gas main flue and a machine head ignition section flue. The outlets of the air boxes below the machine tail section and the flue gas fast heating section communicate with the high temperature flue gas main flue through fluidized bed reactors separately, the outlets of the air boxes below the machine head section communicate with a circulatory flue gas cover on the trolleys of the sintering machine through the circulatory flue gas main flue, and the outlets of the air boxes below the ignition section are connected with the machine head ignition section flue. The sintering flue gas mass-divided directional circulation and on-line denitration system is simple, compact in structure, high in waste heat recovery rate and low in denitration operation cost, denitration equipment investment is saved, and zero input of denitration catalysts and flue gas heating energy consumption is achieved.

Owner:WUHAN UNIV OF SCI & TECH +1

A sintering flue gas denitrification process based on sintering flue gas circulation and soot catalysis

ActiveCN107349783BImprove the environmentReduce dustGas treatmentDispersed particle separationParticulatesPtru catalyst

The invention relates to a sintering flue gas denitration technology based on sintering flue gas circulation and flue dust catalysis. According to the technology, sintering flue gas penetrates a sintered material layer, a basic material, a fine-toothed comb arranged on the bottom of the trolley of a sintering machine, and an air bellow under the trolley under the effect of the suction force of a high pressure draught fan and enters a flue gas pipeline. Along the moving direction of the trolley, the sintering machine is divided into four areas: an ignition section, a machine head section, a flue gas rapid temperature rising section, and a machine tail section. The particles in the sintering flue gas of the machine tail section and the flue gas rapid temperature rising section deposit in the air bellow and flue gas pipeline and then enter a main flue powder hopper. The particles in the main flue powder hopper is delivered to a particle material chamber through a dust pneumatic transmission pipe by pneumatic transmission and then delivered into a fluidized bed denitration reactor to carry out denitration catalysis. The technical process is simple, the dust catalytic denitration can be performed without any purchased denitration catalyst; the waste heat recovery rate is high, the occupied area is small, the technology is environmentally friendly, the denitration equipment investment is little, and the denitration operation cost is low.

Owner:WUHAN WUTUO TECH

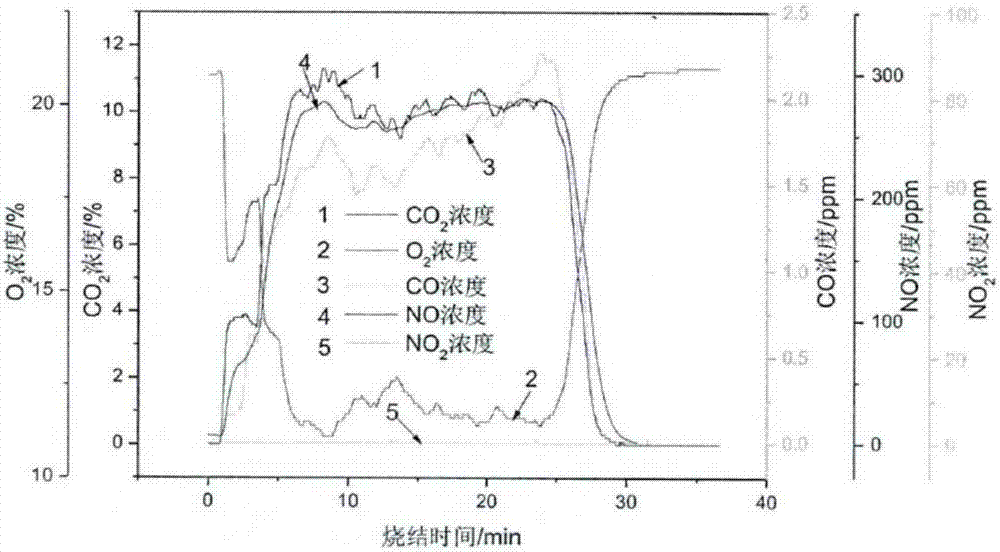

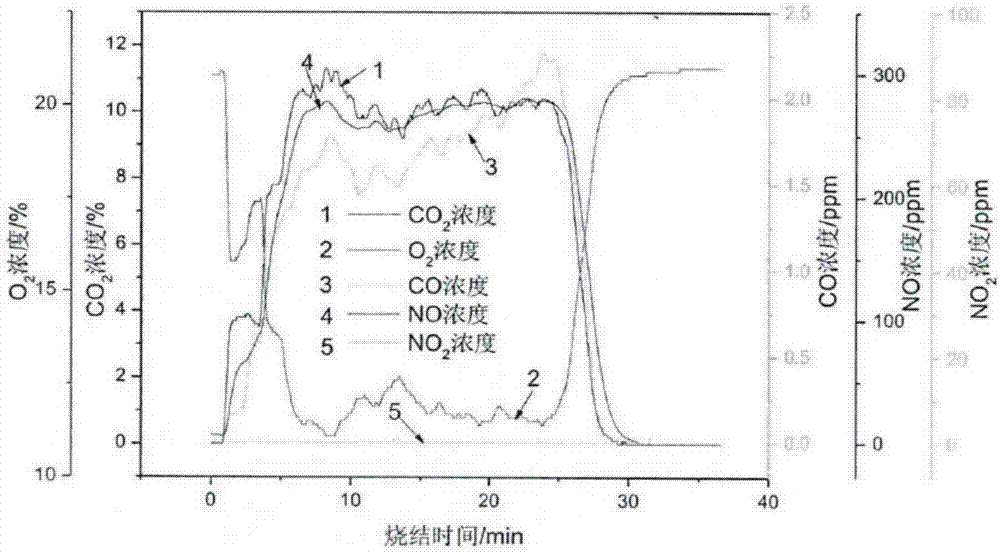

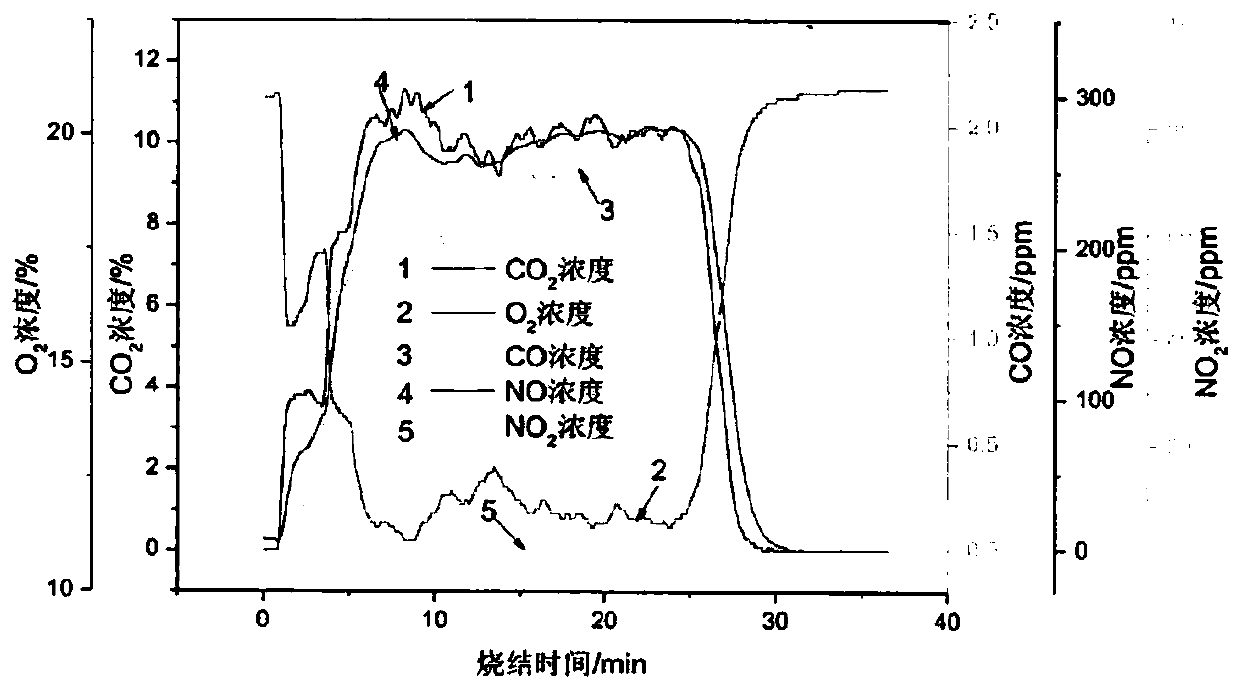

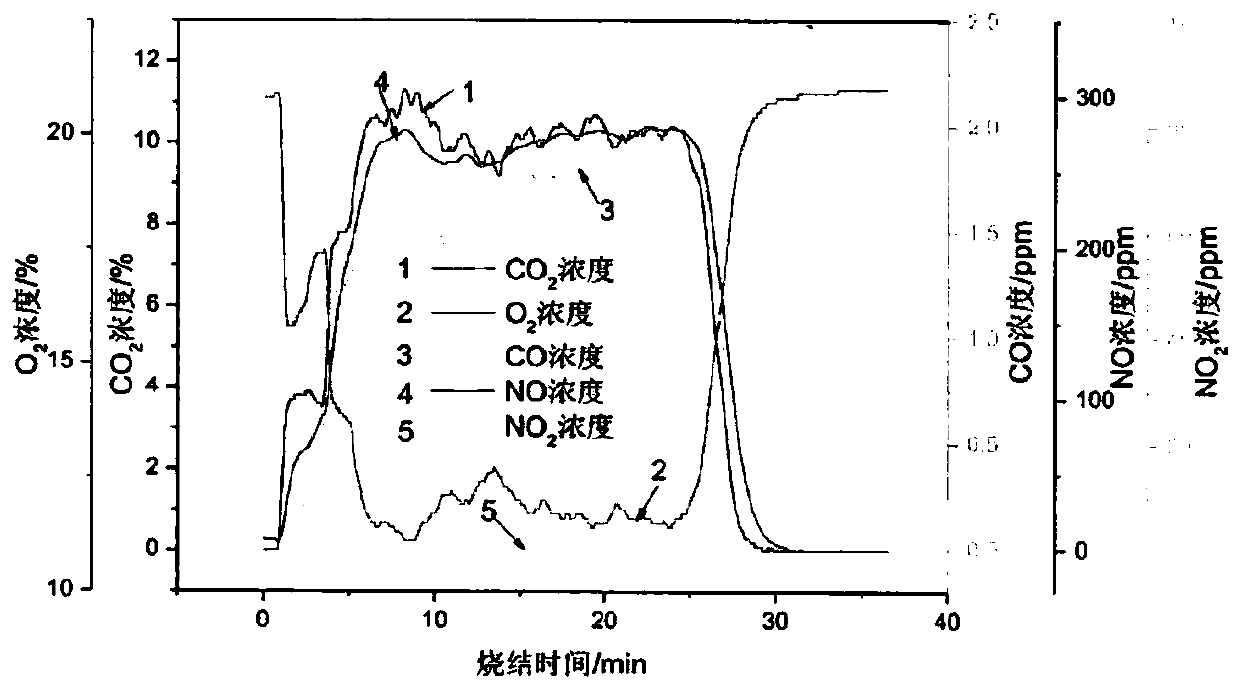

Sintering flue gas circulation low NOx emission process

ActiveCN107166971BRealize online denitrificationIncrease temperatureWaste heat treatmentFlue gasVaporization

The invention relates to a low-NOx emission process for sintering flue gas circulation. According to the technical scheme, sintering flue gas penetrates a sintered material layer, bed charge, a grate on the bottom of a sintering trolley and an air bellow below the trolley to enter a flue gas pipeline, sintering flue gas from a tail segment and a flue gas rapid temperature raising segment region is mixed with sprayed liquid ammonia and ammonia gas formed through vaporization of liquid ammonia under the high temperature in the air bellow, under the catalytic action, a denitration reduction reaction occurs, and the product enters a main flue; and after being collected by the corresponding air bellow, the sintering flue gas from the head segment is led out of the circulating flue gas main flue and fed into a circulating flue gas cover above the sintering trolley, the sintering flue gas enters the sintered material layer again under the suction action of the high-pressure draught fan, the sintering flue gas takes part in the sintering process and is subjected to reduction denitration, and the sintering flue gas penetrates the trolley grate and enters the air bellow again. The process procedure is simple, effective denitration is achieved without purchasing a catalyst, controllability is good, the environment is protected, the equipment investment is saved, the running cost is low, and NOx in the sintering flue gas which is emitted out can be effectively removed.

Owner:武汉钢铁有限公司

Online dust discharging method based on dust remover

InactiveCN112915662ALarge amount of dustImprove filtering effectDispersed particle filtrationTransportation and packagingWater dischargeWater source

The invention discloses an online dust discharging method based on a dust remover. The method comprises the following steps: regularly brushing dust on a filter cartridge or a filter screen, arranging a spray head at the lower part in the dust remover for spraying water, melting the brushed dust in water and discharging the dust from a water outlet pipe, and providing a water source for the spray head by a water tank; arranging a purification tank below the water outlet pipe and dividing into a dirty water area and a pure water area by a filter wall, arranging a filter barrel in the dirty water area, enabling dirty water discharged from the water outlet pipe to be filtered by the filter barrel and then enter the dirty water area, and enabling the dirty water in the dirty water area to be filtered by the filter wall and then enter the pure water area to become pure water; and when dust is brushed off, supplementing purified water in the purified water area into the water tank. Therefore, sewage with larger dust content discharged from the water outlet pipe of the dust remover is firstly filtered by the filter barrel, most impurities can be filtered out in the filter barrel, dirty water passing through the filter barrel enters the dirty water area and permeates the filter wall, and purified water penetrating through the filter wall can be supplemented into the water tank, so that the aim of saving water is fulfilled, the methodr is more environment-friendly, and pipeline accumulation can be prevented.

Owner:杭州金知科技有限公司

Nox emission reduction system based on ignition and sintering of dry mixture

ActiveCN107314677BFull drying effectReduce generationFurnace typesWaste heat treatmentFluidized bedFlue gas

The invention discloses a NOx emission reduction system based on ignition and sintering of a dry mixture. According to the technical scheme, the system comprises a sintering machine; bellows are arranged below trolleys of the sintering machine; the sintering is sequentially divided into four areas including a preheating and drying section, an ignition section, a flue gas quick-heating section and a tail section in the advancing direction of the trolleys; the bellows below the tail section are connected through fluidized bed reactors, a high-temperature flue gas main flue, a high-temperature flue gas dust remover, a high-temperature flue gas circulating fan and a high-temperature flue gas circulating pipe sequentially with a high-temperature circulating flue gas cover located above the preheating and drying section. With the system, the pollution emission amount is small, the recovery rate of waste heat of sintering flue gas is high, no outsourced denitration catalyst is used, and generation of NOx in the flue gas is effectively reduced.

Owner:武汉钢铁有限公司 +2

A catalytic denitrification process of sintering flue gas partitioned circulation flue dust

ActiveCN107413193BSave external heat sourceRealize online denitrificationGas treatmentDispersed particle separationPtru catalystThermodynamics

The invention relates to a sectional circulating soot catalytic denitration process for a sintering flue gas. According to the technical scheme, the process comprises the steps as follows: the sintering flue gas passes through a sintered material layer, a backing material, a bottom grate of a trolley of a sintering machine and an air bellow and enters a flue gas pipeline; the sintering machine is sequentially divided into an ignition segment, a machine head segment, a flue gas rapid heating segment and a machine tail segment along the advancing direction of the trolley; the flue gas pipeline comprises a main flue and a circulating flue gas main flue; the sintering flue gas collected by the machine tail segment, the flue gas rapid heating segment and the air bellow at the lower part of the ignition segment enters the main flue; and the sintering flue gas collected by the air bellow at the lower part of the machine head segment of the sintering machine enters the circulating flue gas main flue, is fed into a circulating flue gas hood at the upper part of the trolley at the machine tail segment and the flue gas rapid heating segment of the sintering machine after dust is removed through a circulating flue gas dust collector and then enters a sintered material layer again. The sectional circulating soot catalytic denitration process is simple in technological process; sintering soot autocatalytic denitration is achieved without outsourcing a denitration catalyst; and the sectional circulating soot catalytic denitration process is good in denitration effect, high in waste heat recovery rate, small in floor area, friendly to environment, low in denitration equipment investment and low in denitration operation cost.

Owner:武汉钢铁有限公司

Autocatalytic denitrification system for sintering flue gas partitioned circulation coupling flue dust

ActiveCN107051202BSave external heat sourceRealize online denitrificationDispersed particle separationThermodynamicsPtru catalyst

The invention relates to a sintering flue gas zoned-circulating coupled soot autocatalysis and denitration system. According to the technical scheme, the sintering flue gas zoned-circulating coupled soot autocatalysis and denitration system comprises a sintering machine, wherein an air box is arranged below a trolley of the sintering machine, an outlet of the bottom of the air box is communicated with a flue gas pipeline, the sintering machine is sequentially divided into an ignition section, a machine head section, a rapid flue gas heating section and a machine tail section in the advancing direction of the trolley, the flue gas pipeline consists of a main flue and a main circulating flue gas flue, the machine tail section, the rapid flue gas heating section and the air box below the ignition section area of the sintering machine are communicated with the main flue, and the air box below the machine head section area is connected with a circulating flue gas cover above the sintering machine through the main circulating flue gas flue and a circulating flue gas dust remover. The sintering flue gas zoned-circulating coupled soot autocatalysis and denitration system is simple, good in denitration effect, high in residual heat recovery rate, small in occupied area, friendly to environment and low in device investment and operating cost and does not need denitration catalysts.

Owner:武汉钢铁有限公司 +2

On-line denitrification process based on multi-stage circulation of sintering flue gas

ActiveCN107456863BFull drying effectReduce generationGas treatmentDispersed particle separationPtru catalystAir blower

The invention discloses a sintering smoke multi-stage circulating based online denitration technology. According to the technical scheme, the technology is characterized in that a sintering machine is sequentially divided into four areas, namely, a preheating drying section, an igniting section, a rapid smoke heating section and a tail section in a trolley marching direction; sintering smoke at the tail section is fed into a high-temperature circulating smoke hood through a main high-temperature smoke channel, a high-temperature smoke dust remover, a high-temperature smoke circulating fan and a high-temperature smoke circulating pipe in sequence; the sintering smoke in the igniting section and the rapid smoke heating section sequentially flows through a main high NOx smoke channel, a high NOx smoke dust remover and a high NOx smoke circulating fan and then is introduced into a high NOx circulating smoke hood; the sintering smoke enters a sintering material layer to be sintered gain; the sintering smoke in the preheating drying section flows through a main low-temperature smoke channel and then is exported through a low-temperature smoke pipe, an electrostatic / cloth bag type dust remover and a main air blower. The technology is small in pollutant emission, high in sintering smoke waste heat recovery rate, and free from external denitration catalysts, so that NOx in the smoke can be effectively decreased.

Owner:武汉钢铁有限公司 +1

Flue gas circulation denitrification system based on sintering flue gas autocatalysis

ActiveCN107029554BImprove the environmentReduce dustGas treatmentDispersed particle separationParticulatesPtru catalyst

The invention relates to a sintering flue gas autocatalysis-based flue gas circulating denitrification system. According to the technical scheme, the system comprises a sintering machine, wherein an air box is arranged at the lower part of a trolley of the sintering machine; an outlet in the bottom of the air box communicates with a flue gas pipe; the sintering machine is sequentially divided into four areas, namely an ignition segment, a machine head segment, a flue gas quick heating segment and a machine tail segment along an advancing direction of the trolley; the outlet of a main flue powder hopper at the lower part of the flue gas pipe connected with the air box in the areas of the machine tail segment and the flue gas quick heating segment is connected with a dust pneumatic conveying pipe; and the outlet of the dust pneumatic conveying pipe is connected to a fluidized bed denitrification reactor through a particle material cabin. The system provided by the invention is simple, high in afterheat recovery rate, small in floor area, friendly to environment, economical in denitrification equipment investment and low in denitrification operation cost, and autocatalytic smoke denitrification is carried out without purchasing a denitrification catalyst.

Owner:武汉钢铁有限公司 +2

Reciprocating material feeding type high-concentration dust producer

ActiveCN102680266BScientific and reasonable inspection and detection of dust suppression efficiencyAffect performance detectionStructural/machines measurementParticle suspension analysisHigh concentrationReciprocating motion

The invention discloses a reciprocating material feeding type high-concentration dust producer which comprises a launching barrel and an air drafting baffle. The launching barrel and the air drafting baffle are connected with a rack fixedly; a shaft sleeve is arranged above the launching barrel along the radial direction; a dust producing rod is arranged in the shaft sleeve; the diameter of the dust producing rod is smaller than the aperture of the inner hole of the shaft sleeve; a reciprocating motion rod is fixedly connected at the upper end of the dust producing rod; a dust depositing tank is arranged above the shaft sleeve; the upper end of the reciprocating motion rod penetrates through the dust depositing tank; the lower end of the reciprocating motion rod is located in the dust depositing tank; the dust depositing tank is communicated with the launching barrel through the shaft sleeve; a bearing installation base is fixed at the upper end of the reciprocating motion rod; a rolling bearing is arranged in the bearing installation base; the rolling bearing is in rolling contact with an eccentric wheel; the eccentric wheel is connected with a speed change device; the speed change device is connected with a motor; a spring is arranged between the reciprocating motion rod and the shaft sleeve; and the air drafting barrel is provided with an original dust gauge opening under the shaft sleeve. The dust producer is in a manner of reciprocating material feeding with large dust production quantity, high dust production concentration and small dust production error.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

A Two-Stage Preheating Air Boiler Using Full Backfiring Finned Water Tube Grate

The invention belongs to the technical field of fire coal, coke and biomass fuel boilers, and provides a two-stage preheating wind boiler using an all-reversal-combustion fin type water tube grate. The problems that energy waste, environment pollution and potential safety hazards are caused by an existing reversal-combustion boiler are solved. The all-reversal-combustion fin type water tube grate is adopted by the boiler, the fire outlet sectional area of the grate is greatly enlarged on the basis of the same grate area, and the combustion speed and combustion temperature are increased; a preheating area and a triple valve structure are adopted, hot air preheated by the air preheating area can be fed into a hearth through a preheating air inlet, the temperature of the furnace is raised, the contact area between hot oxygen and fuel is greatly enlarged, it can be ensured that smoke is fully combusted through multiple times of wind combustion supporting, the fuel utilization rate is increased, the smoke emission temperature is lowered, exhausted smoke does not contain CO, clean combustion is achieved, and meanwhile the potential safety hazards of toxic gas in smoke are eliminated.

Owner:SHANXI XINJUXING BOILER

Coupling process of waste heat recovery and denitrification of sintering dust

ActiveCN107198961BRealize online denitrificationIncrease temperatureGas treatmentDispersed particle separationPtru catalystFlue gas

The invention relates to a sintering smoke quality-divided treatment, waster heat recycling and denitration coupling process. The process is characterized in that sintering smoke passes through a sinter bed, bed charge, a grate at the bottom of a sintering machine trolley and an air box under the sintering machine trolley and then enters a flue gas pipeline; the sintering smoke at a machine tail section and a rapid flue gas heating section passes through air boxes and fluidized bed reactors which correspond to the machine tail section and the rapid flue gas heating section, and then enters a main flue of high-temperature flue gas; the sintering smoke coming from a machine head section is collected by a corresponding air box, is then led out through a main flue of circulatory flue gas, is sent into a circulatory flue gas hood arranged above the sintering machine trolley, and enters the sinter bed again under the action of suction force of a high pressure draft fan; the sintering smoke coming from an ignition section is collected by a corresponding air box and then enters a flue of a machine head ignition section. The process provided by the invention is simple in process flow; a denitration catalyst does not need to be additionally purchased during flue gas quality-divided treatment, so that self-catalysis denitration of the smoke is realized; the process is compact in structure, high in recovery rate of waste heat, less in denitration equipment investment, low in denitration running cost, zero in input of the denitration catalyst and free from flue gas heating energy consumption.

Owner:武汉钢铁有限公司 +2

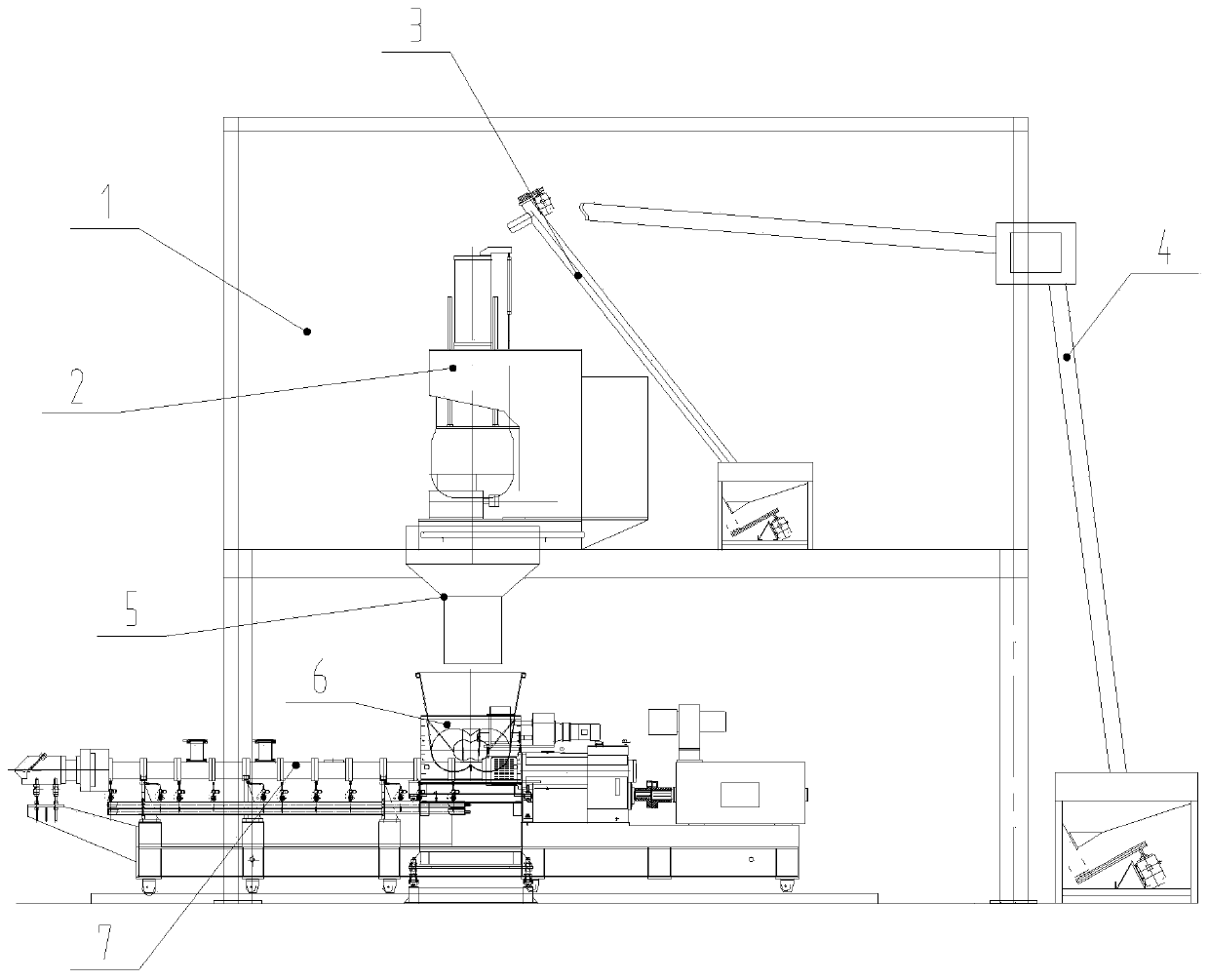

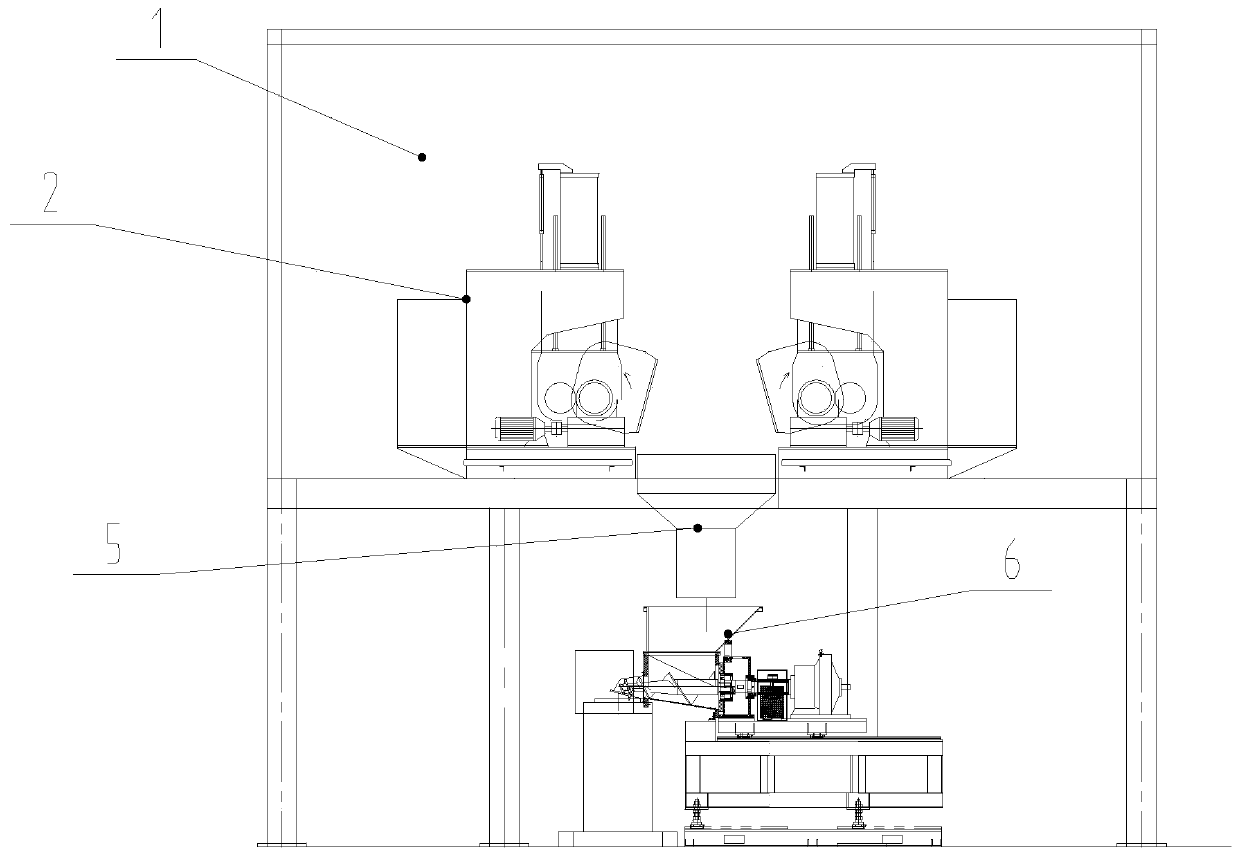

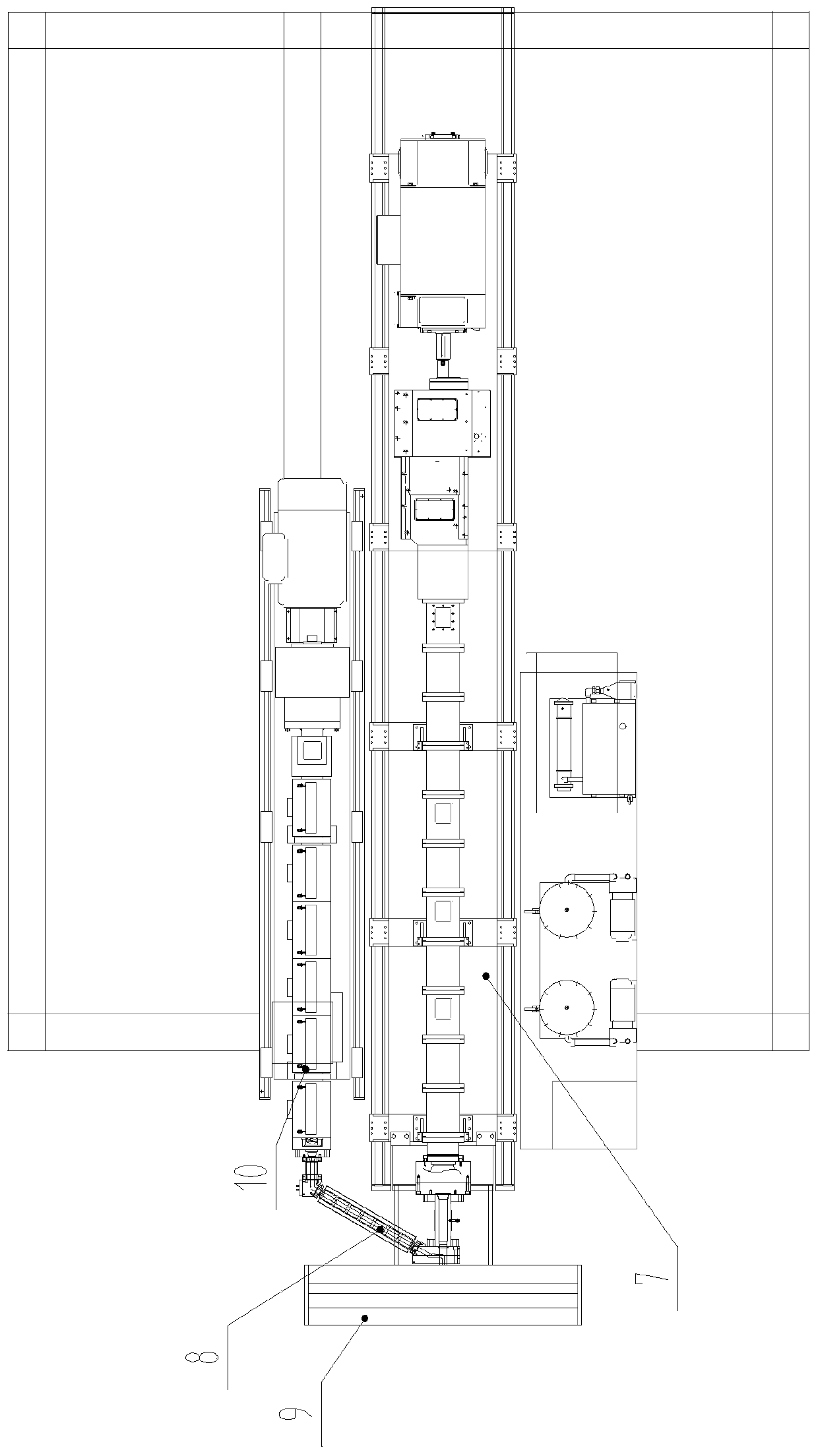

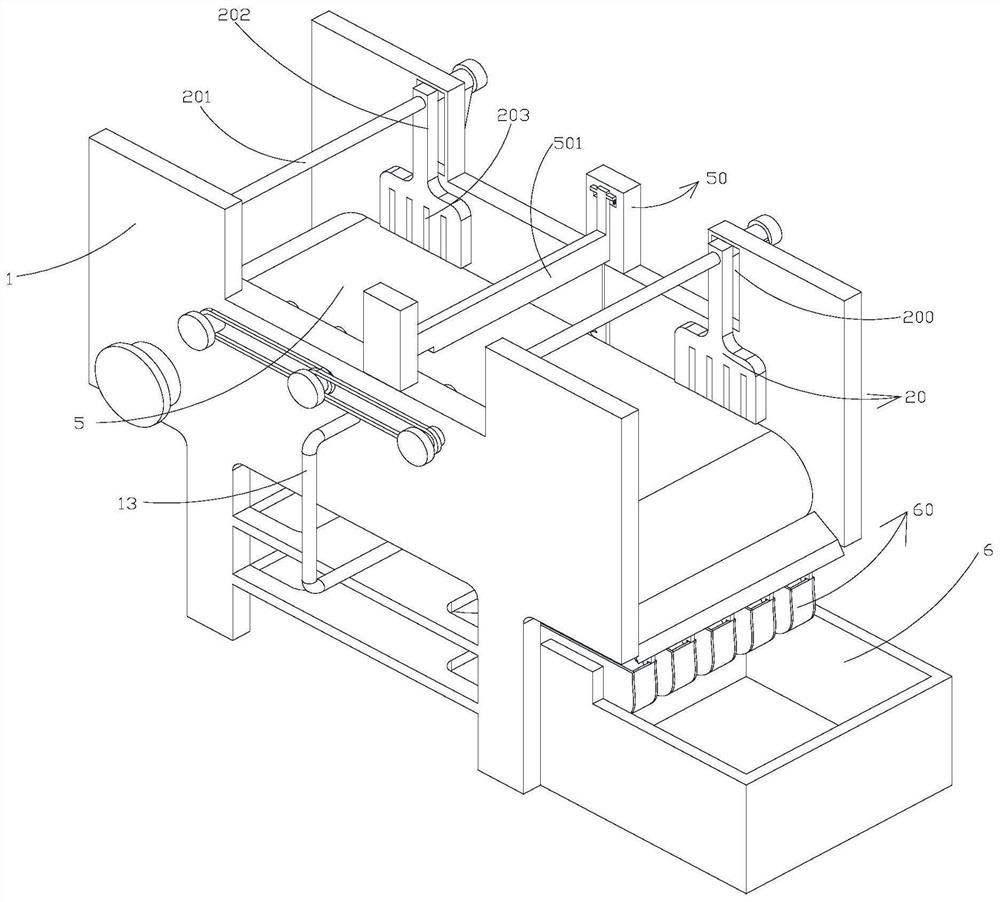

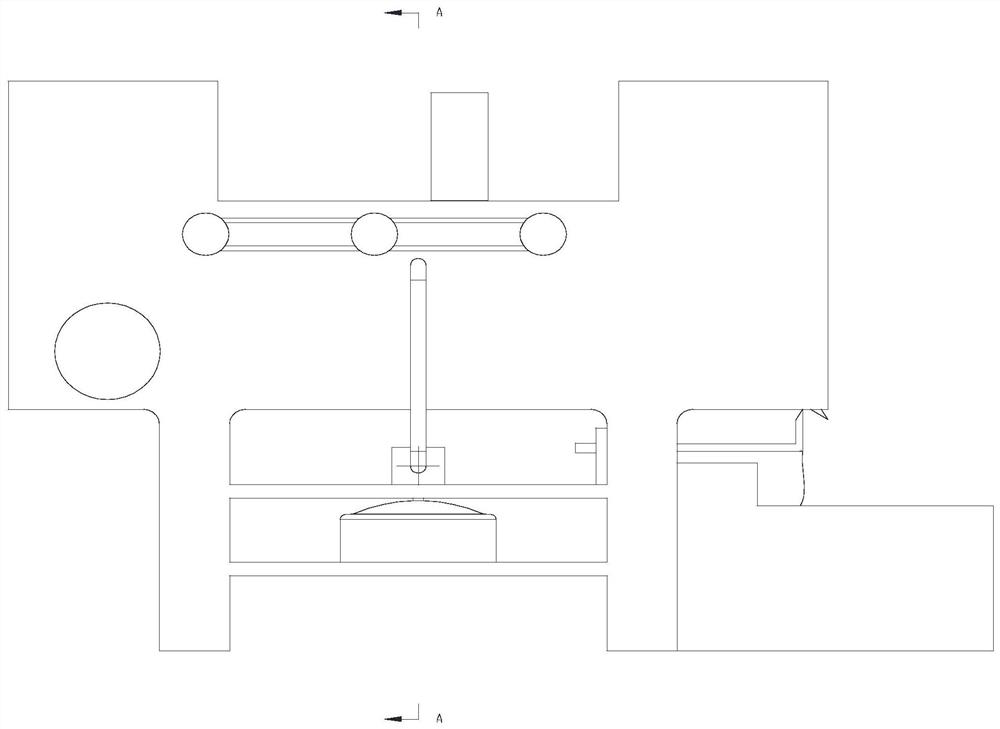

Mixed extrusion system and mixed extrusion method for production of A2 or B1-grade fireproof plate

PendingCN109719920AIncrease extrusion speedImprove efficiencyFlat articlesProcess controlRaw material

The invention discloses a mixed extrusion system and mixed extrusion method for production of an A2 or B1-grade fireproof plate. The mixed extrusion system is adopted in the mixed extrusion method. The mixed extrusion system comprises an internal mixer, a main extruder, a feeder and a screw feeder. The feeder is arranged on the upstream portion of the internal mixer. The discharging end of the feeder is connected with a feed opening of the internal mixer to be used for supplying a raw material for producing an A2 or B1-grade fireproof core layer into the internal mixer. A discharging opening is formed in the bottom of the internal mixer and is connected with a feeding opening of the screw feeder. A discharging opening of the screw feeder communicates with a feeding opening of the main extruder. A core layer sheet forming mold used for extruding and forming the fireproof core layer is arranged at the discharging end of the main extruder. By means of the mixed extrusion system, the A2 orB1-grade core layer can be produced better, the production efficiency is improved, process control is simpler, and the core layer is denser.

Owner:张家港市弘扬机械设备有限公司

A kind of indoor air purification device for office

ActiveCN105944558BImprove elimination effectTo achieve the purpose of dust removalDispersed particle filtrationTransportation and packagingHoneycombAlloy

Owner:中环清新人工环境工程技术(北京)有限责任公司

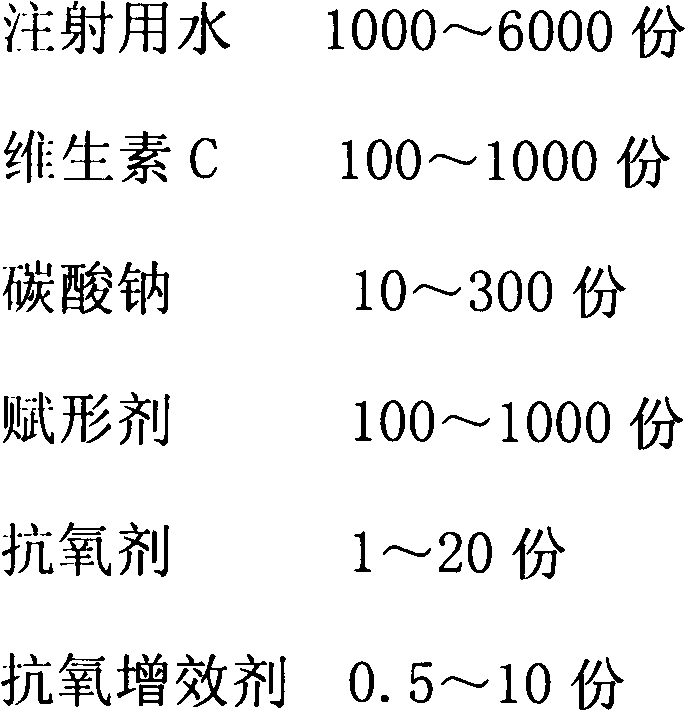

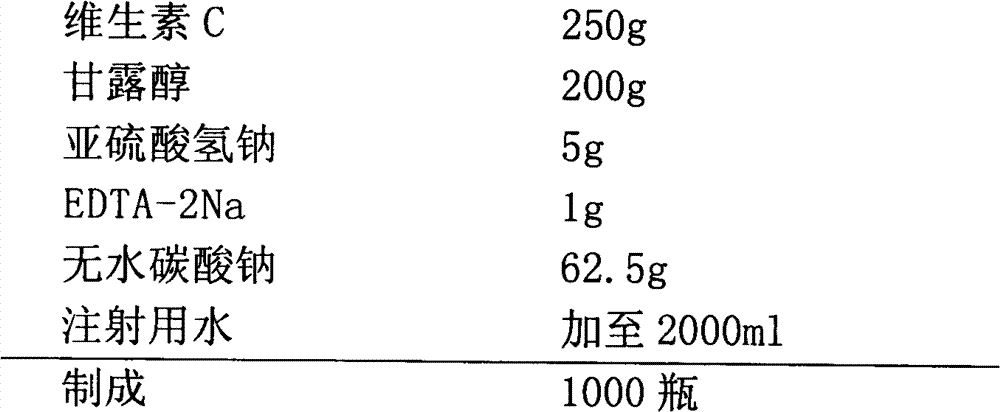

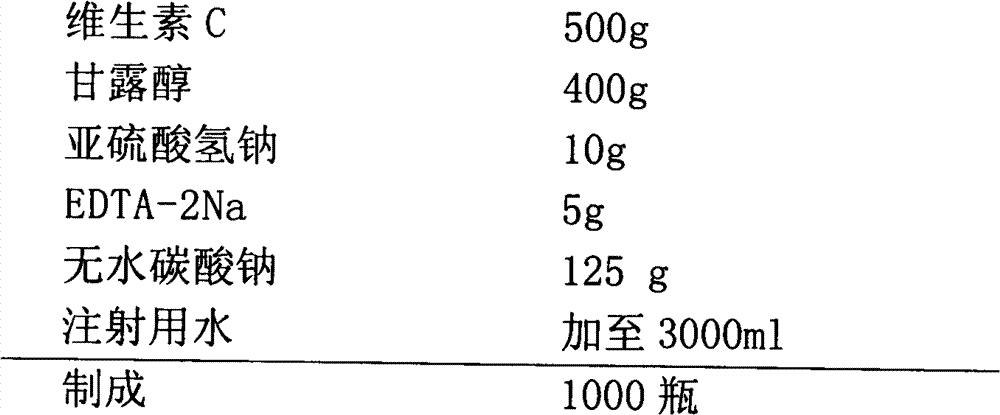

Vitamin C freeze-dried powder for injection and preparation method thereof

InactiveCN103239414ANo pathogenic effectNon-allergenicOrganic active ingredientsPowder deliveryVitamin CFreeze-drying

The invention relates to a vitamin C freeze-dried powder for injection and a preparation method thereof. The invention belongs to the field of medical technology. The vitamin C freeze-dried powder for injection is composed of vitamin C, sodium carbonate, an excipient, an anti-oxidant, an antioxidant synergist and injection water. The preparation method comprises seven steps: filling the injection water with carbon dioxide until the mixture is saturated, preparing a liquid medicine, removing pyrogen, degerming, filtering, loading, freeze-drying and capping. The product provided by the invention has advantages of good external properties, good stability, definite therapeutic effect, simple operation and low cost, and can be widely used in the field of preparations of medicines which are not stable at normal temperature.

Owner:BOSEN BIO PHARMA SHANXI PROVINCE

A large-scale high-efficiency air purification equipment for public places

ActiveCN105879565BStrong pressure resistanceImprove adsorption capacityGas treatmentDispersed particle filtrationParticulatesNano structuring

The invention provides large-size efficient air purification equipment for a public place. The large-size efficient air purification equipment comprises an air inlet with a flange, an air outlet, provided with a flange, of a connection short pipe, a shell and a draught fan located in the shell, a particle adsorption device and a pressurizing device, and a base, and further comprises a washing device of the particle adsorption device and an anaerobic acidulation degradation device located at the bottom of the shell, wherein the washing device is located at the top of the shell; one end of the air outlet of the connection short pipe is further connected with an air-liquid separator; the particle adsorption device comprises a cavity; a titanium pipe is arranged inside the cavity; the surface of the titanium pipe is of a honeycomb-shaped titanium dioxide nano structure; the titanium pipe forms a bent loop structure in the cavity; the diameter of the titanium pipe is 3mm-10mm; and the large-size efficient air purification equipment has a good pressure-bearing capability, a strong PM2.5 (Particulate Matter 2.5) adsorption capability, large dust accumulation and long service life, and can also realize degradation washing of the titanium pipe.

Owner:中环清新人工环境工程技术(北京)有限责任公司

Muck transportation equipment for foundation pit construction

PendingCN113026855APrevent fallingGuaranteed stabilityUsing liquid separation agentSoil-shifting machines/dredgersArchitectural engineeringMechanical engineering

The invention discloses muck transportation equipment for foundation pit construction. The muck transportation equipment for foundation pit construction comprises a rack, a first conveying roller, a second conveying roller and a rotating roller, wherein the first conveying roller and the second conveying roller are arranged on the rack; the rotating roller is arranged between the first conveying roller and the second conveying roller; and a dust falling device comprises a water supply cavity formed in the rack, a water pump arranged below the water supply cavity, a water supply pipe used for connecting the water pump and the water supply cavity, a water tank arranged below the water pump, and a water pumping pipe used for connecting a water tank and the water pump. According to the muck transportation equipment for foundation pit construction provided by the invention, when water is sent out from a first water outlet and a second water outlet, water is sprayed to muck during transportation, so that the dust falling effect is started, and the situation that the dust content in air is large is prevented; and secondly, due to the fact that in the water spraying process, rolling wheels can make contact with a conveying belt, the muck on the conveying belt fluctuates in operation, gaps exist between the muck, and dust in the muck can be relatively sprayed with water in the water spraying process, so that the dust content in the air is greatly reduced.

Owner:徐雯洁

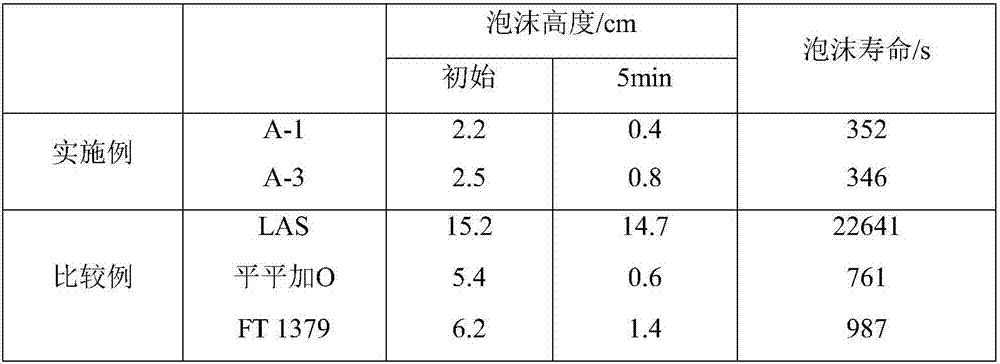

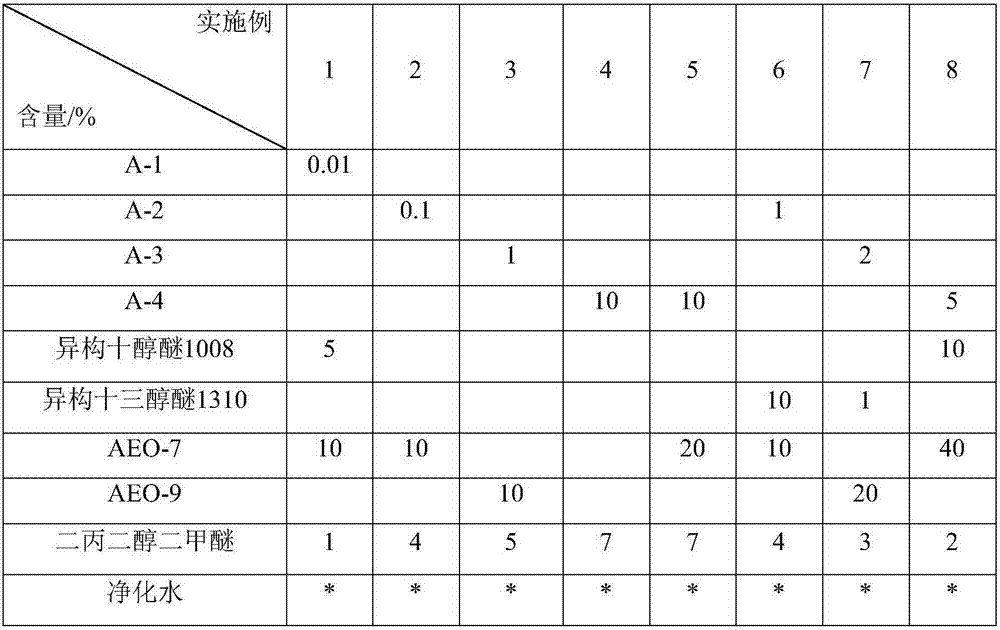

A kind of preparation method of surfactant for detergent

ActiveCN104059783BImprove decontamination abilityEasy to rinseOrganic detergent compounding agentsSurface-active detergent compositionsFiberAlcohol

Owner:SHENZHEN SELEN SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com