A Two-Stage Preheating Air Boiler Using Full Backfiring Finned Water Tube Grate

A technology for preheating air and fins, which is applied to the grate, water heater, and grate of hollow grate bars, which can solve the problems of environmental pollution, potential safety hazards, waste of energy, etc., so as to improve the utilization rate and increase the burning speed. and combustion temperature, the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

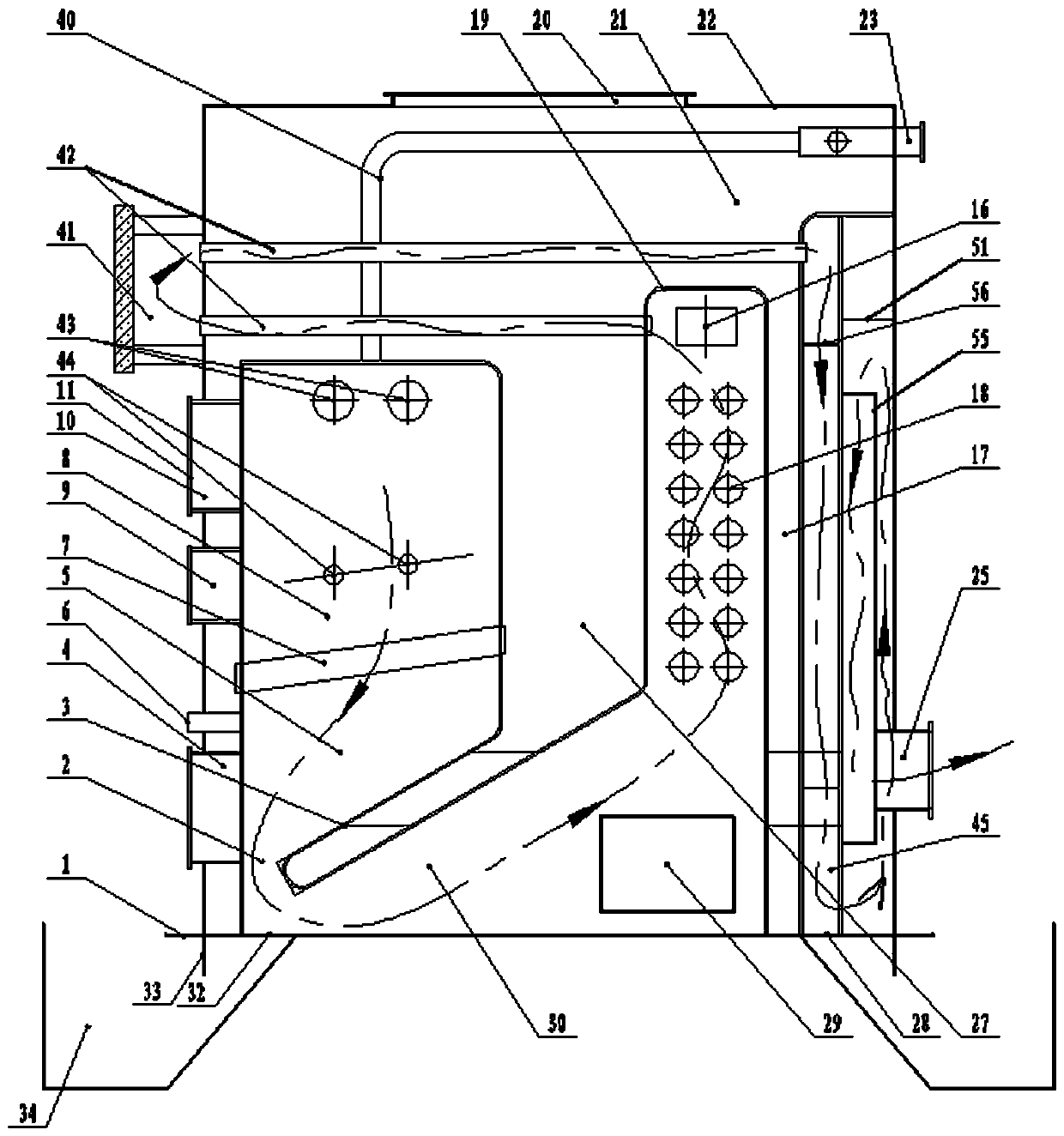

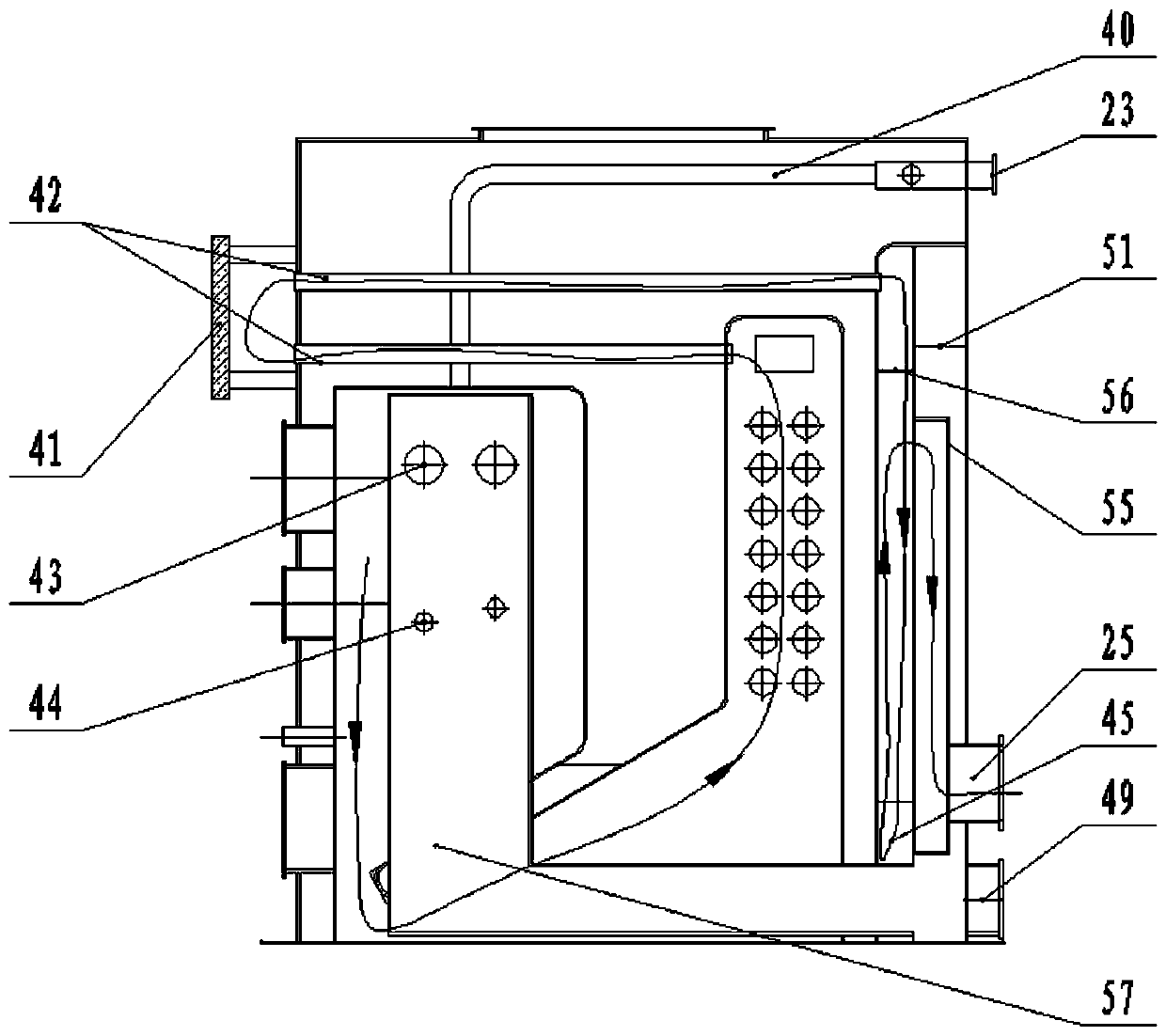

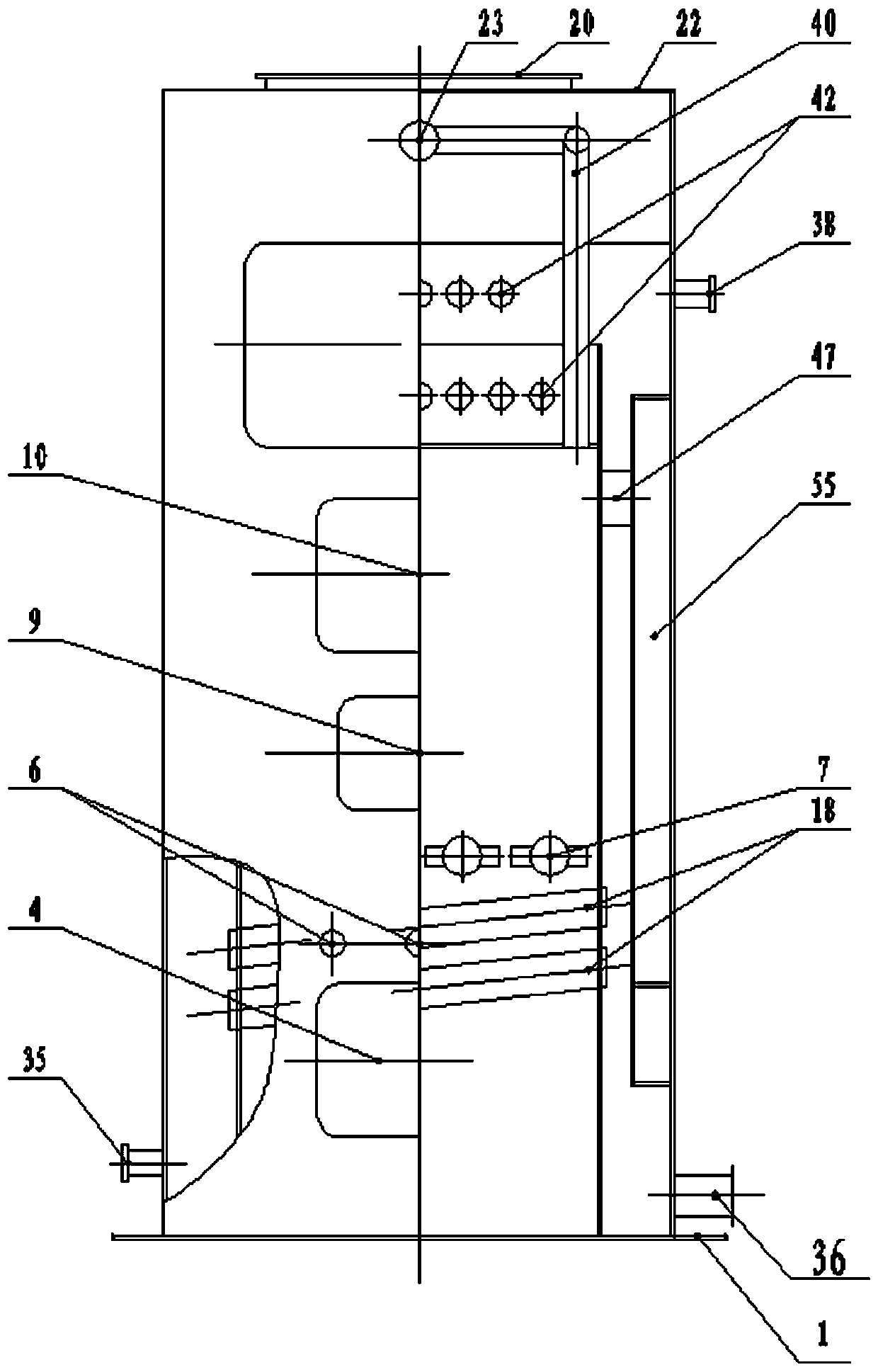

[0040] Such as figure 1 , 2 , A kind of two-stage preheating air boiler using the full back-fired finned water tube grate shown in 3 and 4 includes a furnace body made of an inner tank 19 and an outer shell 22 and a base 1 supporting the furnace body. The interior of the furnace body is divided into a feeding chamber 8, a combustion chamber 5, a heat-absorbing area 30 and an air preheating chamber, which are successively connected by the smoke-blocking return device 3, the back-burning finned water tube grate 7, the smoke-blocking return plate 17 and the furnace return plate 27. In the heat zone, a number of heat-absorbing pipes 18 are installed in the heat-absorbing zone 30 , and a fire outlet 2 is provided at the bottom of the combustion chamber 5 . The charging chamber 8 and the combustion chamber 5 are separated by the back-burning finned water tube fire grate 7, the feeding chamber 8 is located above the combustion chamber 5, and the heat-absorbing zone 30 and the air pr...

Embodiment 2

[0057] Such as Figure 5 , 6 In the schematic diagram of the boiler structure of Scheme 2 shown, there are also a number of ash and flue gas vents 14 that pass through the feeding chamber 8 and the heat absorption area 30 on the upper part of the furnace return plate 27, and the ash and flue gas vents 14 are An adjustment plate 15 is provided. When stopping the furnace or sealing the fire, open the regulating plate 15 on the ash and flue gas vent 14, open the regulating valve at the flue gas vent 23 at the same time, and close the valve of the primary damper 12, and open the secondary regulating valve of the combustion chamber. Damper 6 allows residual air to be discharged to realize safe operation.

[0058] It can be seen from this that the structural difference between Scheme 2 (Example 2) and Scheme 1 (Example 1) lies in:

[0059] 1. The liner in Scheme 1 is a special-shaped structure, that is, the smoke-shielding return plate 17 and the furnace return plate 27 are direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com