Sintering flue gas autocatalysis-based flue gas circulating denitrification system

A technology of flue gas circulation and sintering flue gas, which is applied in the field of flue gas circulation and denitrification system, can solve the problems of waste heat of sintering flue gas, large investment in flue gas denitrification, high waste heat recovery rate, etc., achieves reduction of NOx emissions and broad market application The effect of the foreground, smoke and dust with a large amount of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

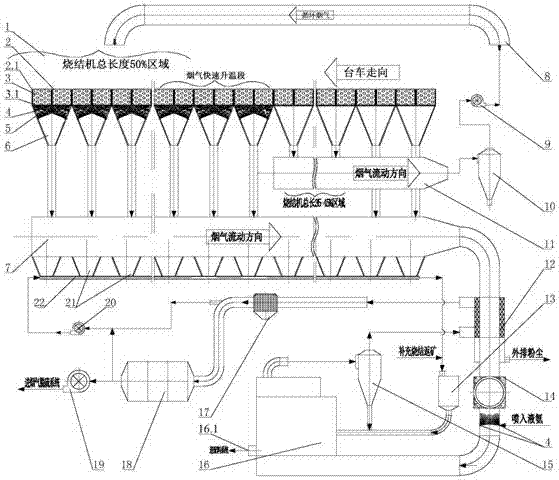

[0043] see figure 2 , including a sintering machine 2, a bellows 6 is provided under the trolley 2.1 of the sintering machine 2, and the outlet at the bottom of the bellows 6 is connected to the flue gas pipeline, and the sintering machine 2 is sequentially divided into an ignition section, a head section, a smoke Gas rapid heating section and tail section 4 areas, the flue gas pipeline is composed of main flue 7 and circulating flue gas main flue 11, the tail section, flue gas rapid heating section and ignition section of the sintering machine 2 The air box 6 below the area is connected to the main flue 7, and the bellows 6 below the nose section area is connected to the main flue 11 of circulating flue gas; wherein, the bottom of the main flue 7 is provided with a main flue powder hopper 21, and the main flue powder The bottom of the hopper 21 is connected to a dust pneumatic conveying pipe 22 , and the outlet of the dust pneumatic conveying pipe 22 is connected to the flui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com