Online dust discharging method based on dust remover

A technology for dust collectors and dust, which is applied in the field of online dust removal based on dust collectors. It can solve problems such as easy blockage of pipes, easy impact on the environment, and large amount of sewage sedimentation, so as to save water, prevent pipe accumulation, and achieve good filtration performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

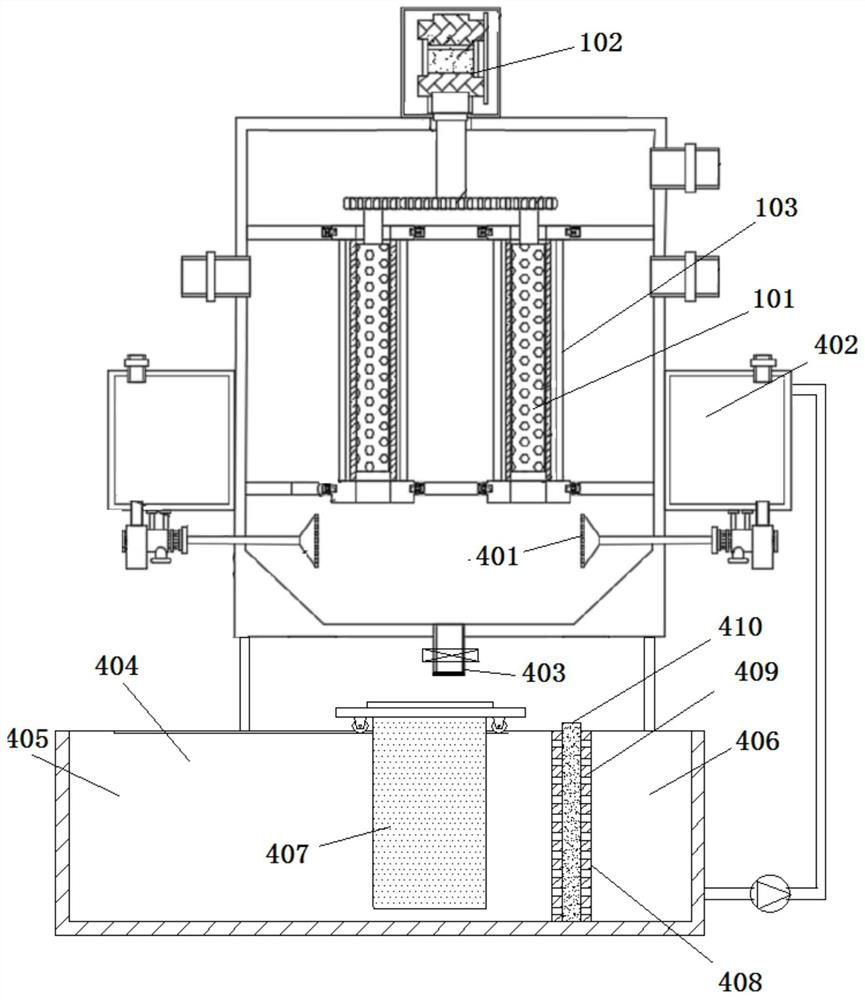

[0032] Such as figure 1 As shown, the online dust removal method based on the dust collector described in this embodiment, wherein the dust collector is a bag filter for rotating and cleaning the filter cartridge. There is a motor 102 on the top that is connected to the filter cartridge 101, and a cleaning brush 103 is installed on the side of the filter cartridge 101. The motor 102 drives the filter cartridge 101 to rotate, so as the filter cartridge 101 rotates, the dust accumulated in the filter cartridge 101 during the dust removal process The dust on the brush will be brushed off by the cleaning brush 103;

[0033] In this method, the dust on the filter cartridge is regularly brushed off, and a nozzle 401 is installed in the lower part of the dust collector to spray water, and the brushed dust is melted into the water and discharged from the water outlet pipe 403;

[0034] There are two connected water tanks 402 on the side of the dust collector, and the water tanks 402 ...

Embodiment 2

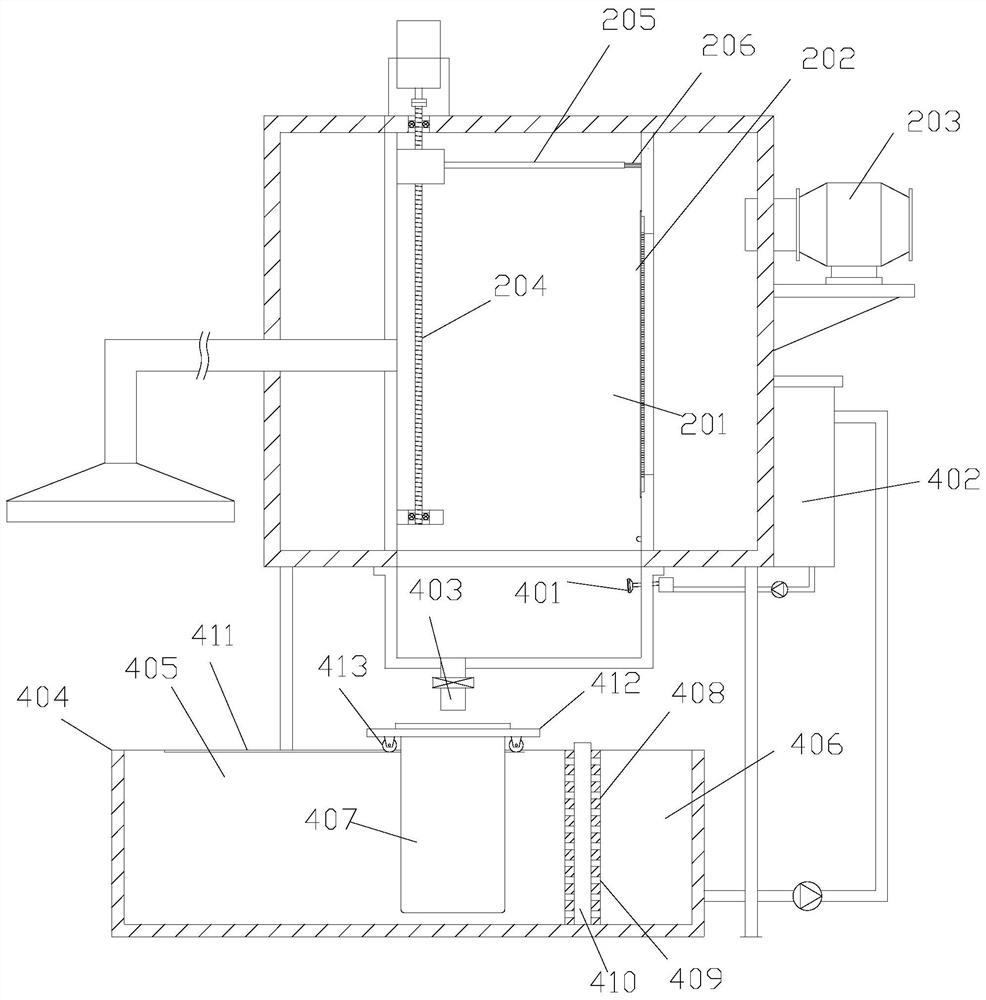

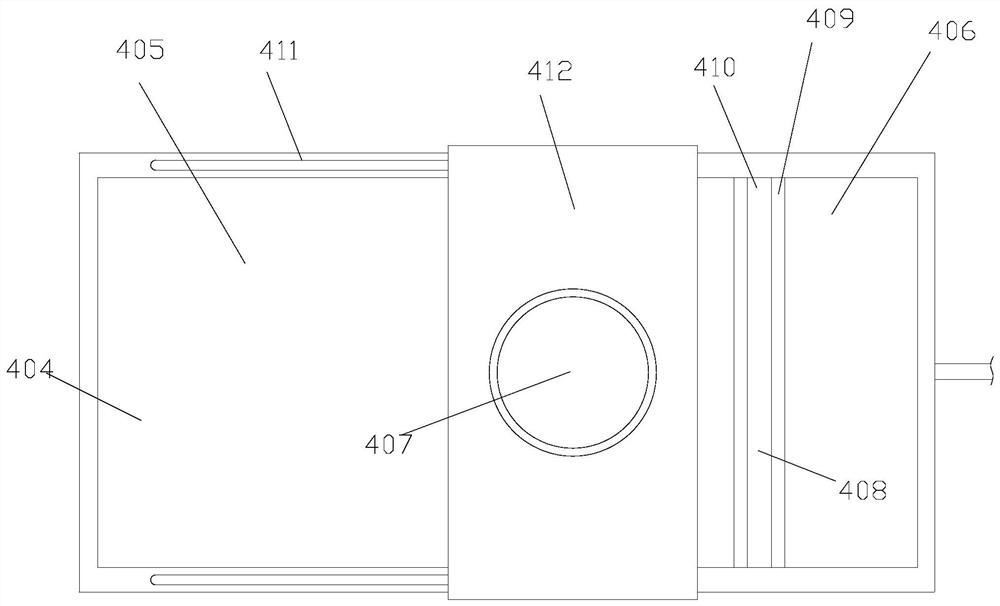

[0040] Such as figure 2 , 3 As shown, the online dust removal method based on the dust remover described in this embodiment, the dust remover is a single-sided filter screen dust remover, a filter chamber 201 is arranged in the dust remover, the rear side of the filter chamber 201 is a filter screen 202, and the filter chamber 201 is connected to the intake pipe, and the rear side of the filter chamber 201 is connected to the exhaust fan 203. After the exhaust fan 304 works, the external air enters the filter chamber 201, and the air is filtered through the filter screen 201, and the clean air is discharged from the exhaust fan 203. A lift drive mechanism 204 is provided in the chamber 201, and the lift drive mechanism 204 drives the lift plate 205 to move up and down. The edge of the lift plate 205 is provided with bristles 206. During the up and down movement, the bristles 206 brush off the dust on the filter screen 201;

[0041] This method regularly brushes off the dust ...

Embodiment 3

[0049] The online dust removal method based on the dust remover described in this embodiment, the dust remover is a four-sided filter net dust remover, such as Figure 4-8 As shown, it includes a casing 301, an air inlet pipe 302, an air outlet pipe 303 and an exhaust fan 304. The casing 301 is provided with a filter chamber 306 surrounded by filter plates 305 on all sides, and the inlet of the air outlet pipe 303 is arranged outside the filter chamber 306. , the exhaust fan 304 is connected to the air outlet pipe 303; the middle part of each filter plate 305 is provided with an opening 307, the inner wall of the filter plate 305 is provided with a concave ring 308, and a porous plate 309 is arranged in the concave ring, and a filter plate 305 is installed on the inner surface. The filter screen 310 attached to the perforated plate 309; the bottom of the casing 301 is provided with a water tank 311 communicating with the filter chamber, and the top of the water groove 311 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com