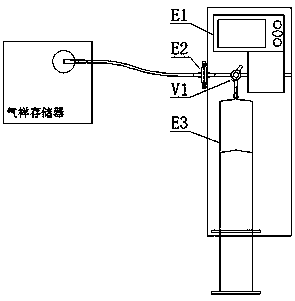

Device for collecting trace dust in gas and method for detecting particle diameter and content of particles

A technology for collecting gas and dust particles, applied in measuring devices, particle and sedimentation analysis, sampling devices, etc., can solve problems such as dust content limitations, and achieve the effect of simple sampling methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1. When the sample gas volume is less than 100mL and the dust content is less than 5mg / L, that is, when the total amount of dust is less than 0.5mg, the dust filter E2 selects the filter membrane of perethylene chloride filter membrane, puts the filter membrane into the dust filter E2 and Connect one end of it to the three-way valve V1;

[0032] Step 2. Connect the storage device containing the gas sample to the other end of the dust filter E2, and rotate the three-way valve V1 to connect the dust filter E2 and the gas volume flow meter E1, so that the gas in the gas sample storage device passes through the gas at a slow and uniform speed. Volume flow meter E1, record the total gas volume Vg = 80mL, remove the gas sample storage after the gas is exhausted;

[0033] Step 3. Dissolve the dust-capturing perchlorethylene filter membrane in 1mL of butyl acetate, and finally spread the suspension evenly on the glass slide with an area of S=1.0cm 2 ;

[0034] Step 4, ...

Embodiment 2

[0040] Step 1. When the sample gas volume is less than 100mL, the dust content is greater than 5mg / L, and the total amount of dust is less than 0.5mg, the dust filter E2 selects the filter membrane perethylene chloride filter membrane, and puts the filter membrane into the dust filter E2 and One end of it is connected with the three-way valve V1;

[0041] Step 2. Connect the storage device containing the gas sample to the other end of the dust filter E2, and rotate the three-way valve V1 to connect the dust filter E2 and the gas volume flow meter E1, so that the gas in the gas sample storage device passes through the gas at a slow and uniform speed. Volume flow meter E1, record the total gas volume Vg = 50 ~ 100mL, remove the gas sample storage after the gas is exhausted;

[0042] Step 3. Dissolve the dust-capturing perchlorethylene filter membrane in 1-2mL of butyl acetate, and finally spread the suspension evenly on the glass slide, with an area of S=1-2cm 2 ;

[0043] S...

Embodiment 3

[0046] Step 1. When the sample gas volume is less than 100mL, the dust content is greater than 5mg / L, and the total amount of dust is greater than or equal to 0.5mg, the filter membrane of dust filter E2 is cellulose acetate filter membrane, and the filter membrane is loaded into dust filter E2 and weighed. Weight m1=1.7538g, and then connect one end of it with the three-way valve V1;

[0047] Step 2. Connect the air bag containing the gas sample to the other end of the dust filter E2, rotate the three-way valve V1, connect the dust filter E2 and the gas volume flow meter E1, and squeeze the air bag to make the gas flow as slowly as possible. Pass through the gas volume flow meter E1 at a constant speed, record the total gas volume Vg=78mL, and remove the air bag;

[0048] Step 3. After capturing the dust, remove the dust filter E2, weigh it as m2=1.7549g, reconnect its original end to the three-way valve V1, rotate the three-way valve V1, and connect the syringe E3 containing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com