A catalytic denitrification process of sintering flue gas partitioned circulation flue dust

A technology for sintering flue gas and catalytic denitration, which is applied in separation methods, gas treatment, and dispersed particle separation, etc., can solve the problems of high operating cost, large heat energy consumption, and high cost, and can reduce post dust, reduce flue gas temperature, and reduce The effect of drag loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

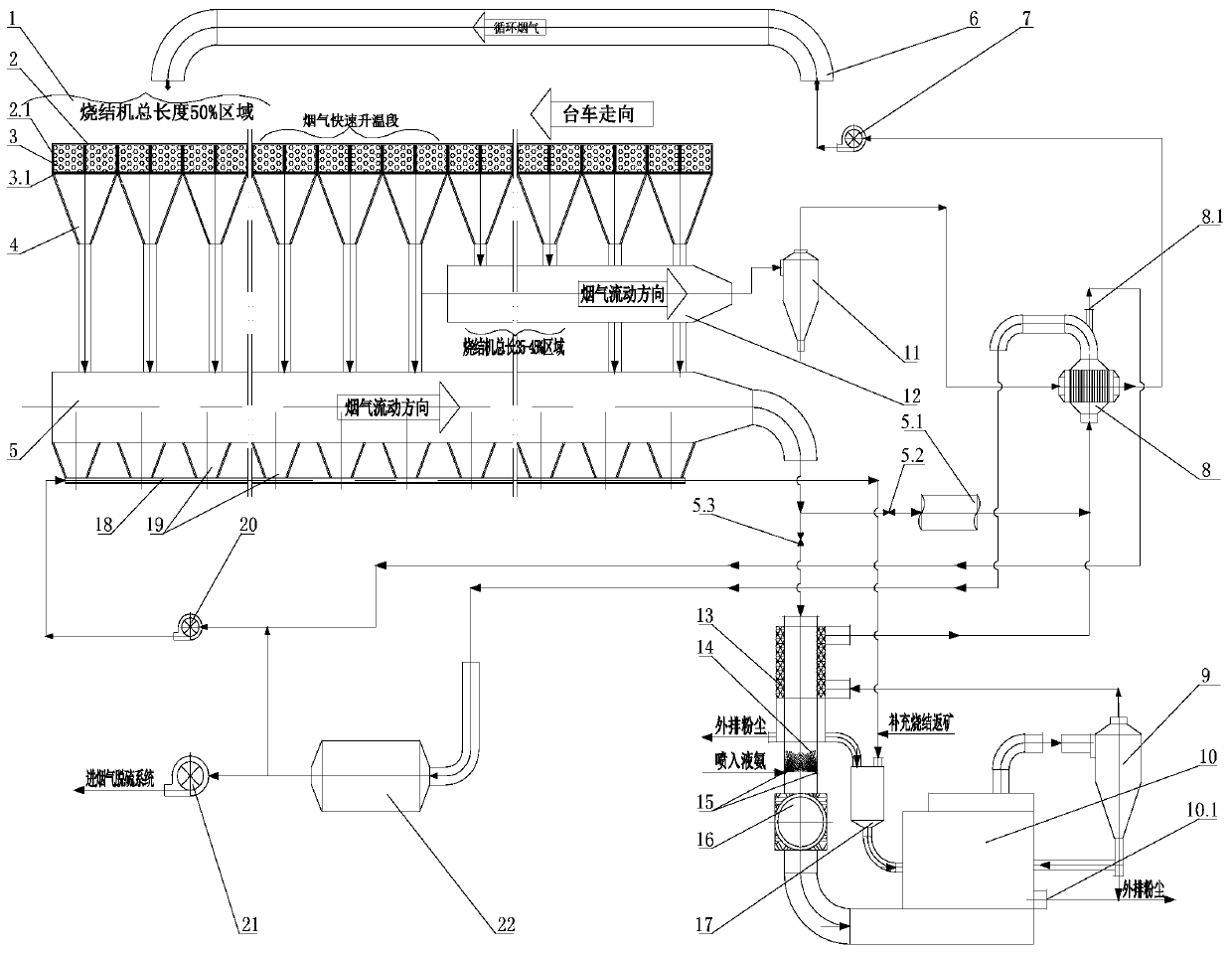

[0040] see figure 2 , the system of the present invention includes a sintering machine 2, a bellows 4 is provided under the trolley 2.1 of the sintering machine 2, and the outlet at the bottom of the bellows 4 is connected to a flue gas pipeline, and the sintering machine 2 is sequentially divided into an ignition section, a machine There are four areas: the head section, the flue gas rapid heating section and the tail section. The flue gas pipeline is composed of the main flue 5 and the circulating flue gas main flue 12. The tail section of the sintering machine 2 and the flue gas rapid heating The air box 4 below the ignition section and the area of the ignition section communicates with the main flue 5, and the main flue 5 is sequentially connected to the tube side or shell side of the denitration flue gas heat exchanger 13, the flue gas heater 16 and the fluidized bed denitrification reactor 10 , the flue gas outlet of the fluidized bed denitrification reactor 10 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com