Real-time monitoring sensor for durability of concrete structures and fabricating method thereof

A concrete structure, real-time monitoring technology, applied in the field of corrosion and protection of reinforced concrete structures, can solve the problems that affect the stability and service life of the reference electrode, cannot truly and accurately reflect the corrosion rate of steel bars, and cannot effectively reduce electrolyte loss, etc., to achieve Good stability and economy, improve stability and service life, reduce the effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

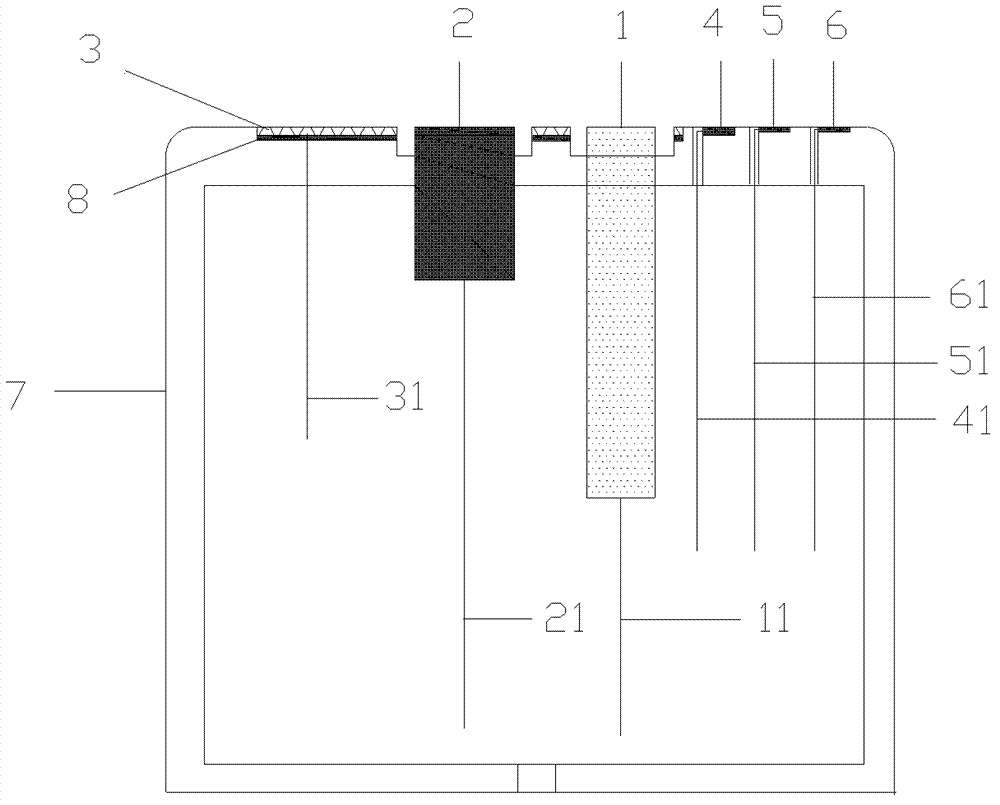

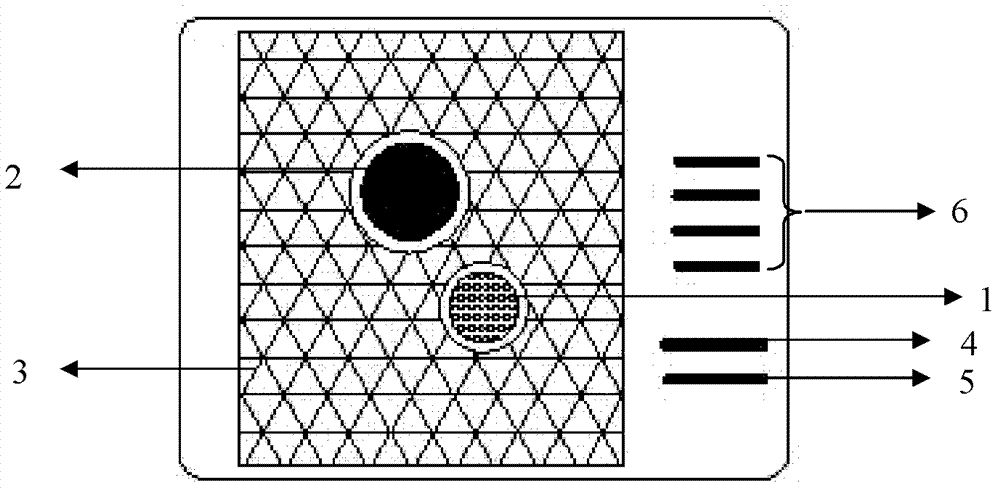

[0021] figure 1 with figure 2 It is a schematic diagram of the vertical and horizontal structure of the multifunctional sensor developed by the present invention. In order to have a clearer understanding of the structure of the multifunctional sensor, figure 1 Lieutenant Rebar Electrode, Reference Electrode, Cl - Probes, pH probes, and concrete resistivity probes are arranged in sequence. The arrangement of electrodes and probes in the embodiment is as follows figure 2 Shown.

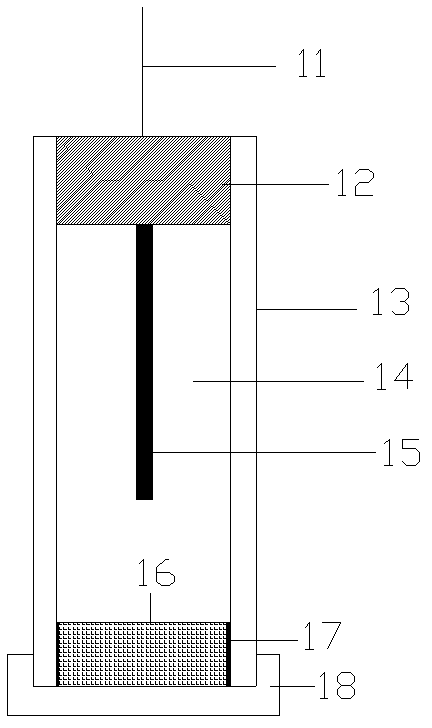

[0022] Such as figure 1 with 2 The sensors shown for real-time monitoring of the durability of concrete structures mainly include: Ag / AgCl gel electrolyte reference electrode 1, steel bar electrode 2, auxiliary electrode 3, Cl probe 4, pH value probe 5, concrete resistivity Monitoring probe 6, sensor housing 7, copper cables 11, 21, 31, 41, 51 and 61, and epoxy resin connection layer 8 between auxiliary electrode 3 and housing 7.

[0023] The specific manufacturing method of the multifunctional sensor for r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com