Multipoint positioning back plate

A multi-point positioning and backplane technology, which is applied in the direction of instruments, casings/cabinets/drawer components, static indicators, etc., can solve problems such as easy twisting and bending, low structural strength, and small storage space. Achieve the effect of improving strength, large accommodation space and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

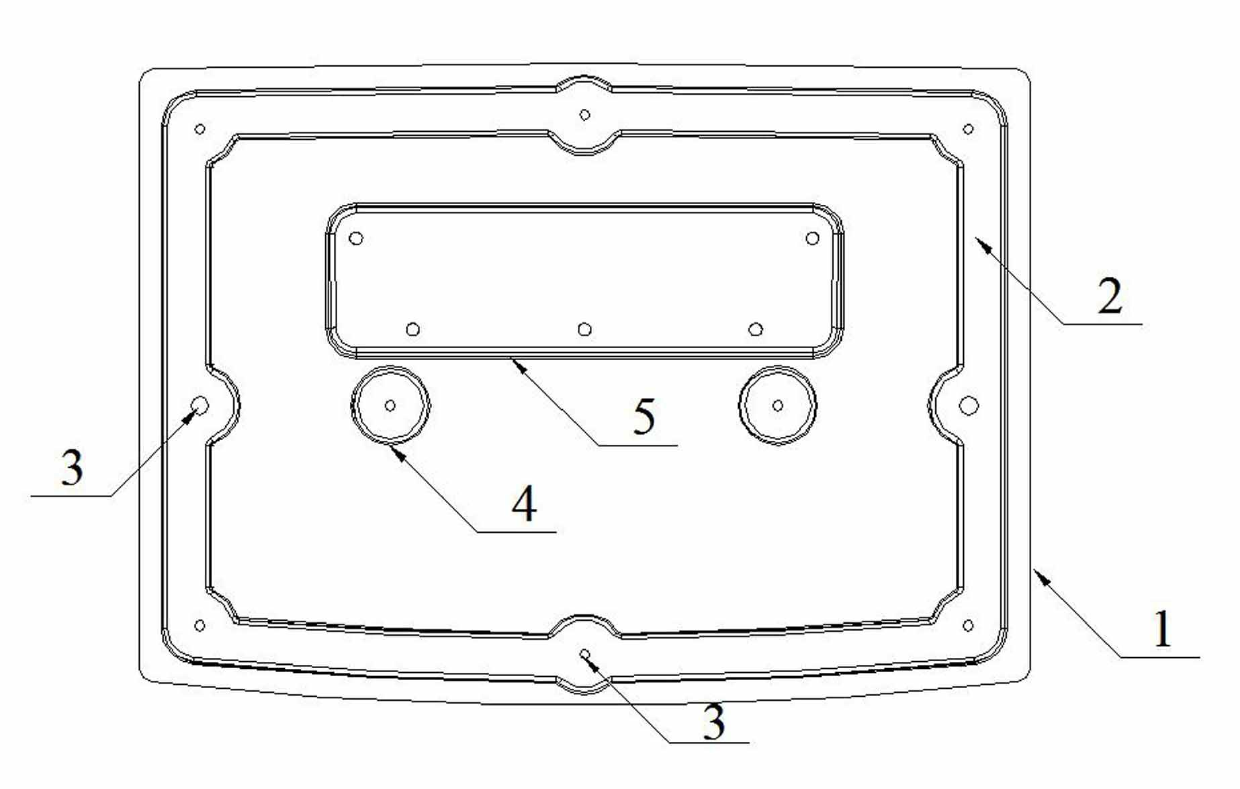

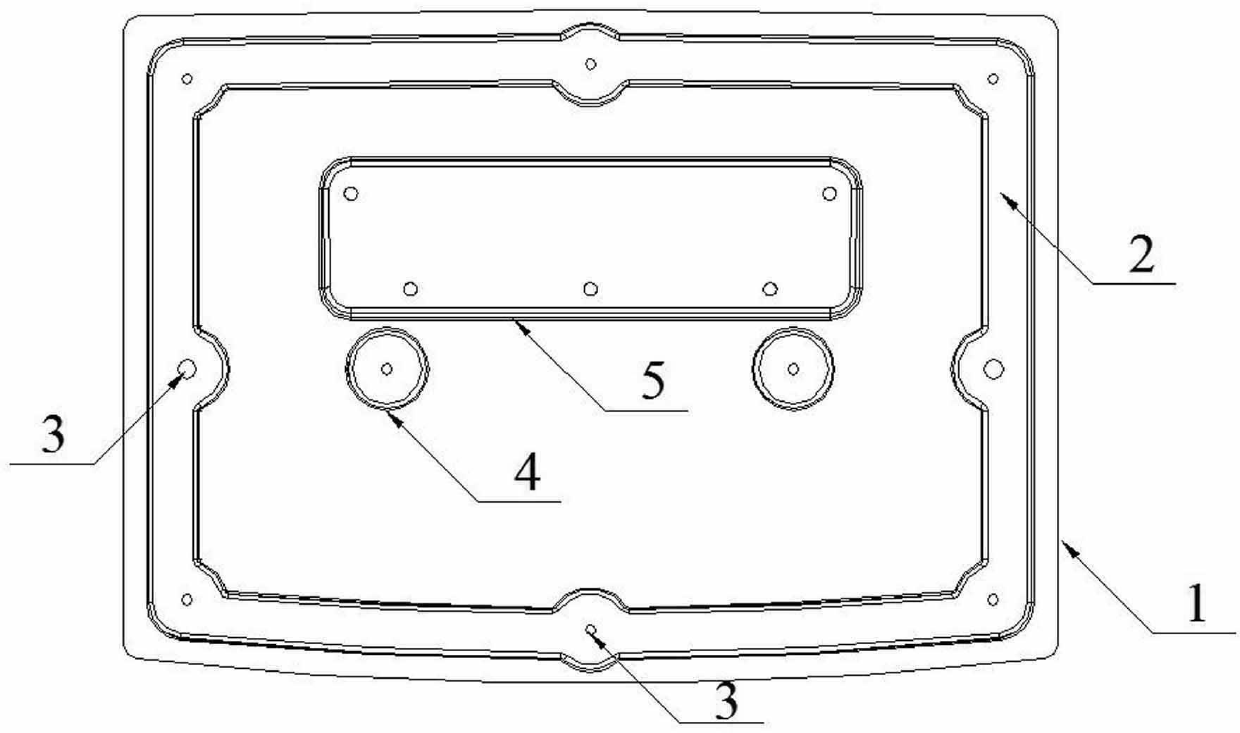

[0014] The multi-point positioning backboard of the present invention includes: a backboard main body 1 , a protruding ring 2 , a fixing convex hull 3 , a positioning convex hull 4 and an accommodating convex hull 5 . Specific reference figure 1 shown.

[0015] On the rectangular backboard main body 1, a protruding ring 2 is formed near the edge, and a plurality of fixed convex bumps 3 are formed on the protruding ring 2. Since the fixed convex bumps 3 are formed on the raised ring belt 2, so when the backboard is connected and fixed with the plate structure used to fix the backboard, the raised ring belt 2 plays a role of supporting and stabilizing, and makes the fixed convex bump 3 on it less prone to twist and tear during stamping. Bending greatly improves the strength of the structure.

[0016] As a preferred solution, the backplan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com