Protrusion forming member and method for manufacturing protrusion forming member

A manufacturing method and component technology, which are applied to the manufacturing field of protrusion-forming components and protrusion-forming components, can solve the problems of low production efficiency, long processing hours, poor material yield, etc., and achieve the effects of improving production efficiency and reducing processing hours.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, the case where the protrusion forming member of the present invention is applied to the movable contact body of a multidirectional input device will be described below. However, the application object of the protrusion forming member of the present invention is not limited to this, and can be appropriately changed. In addition, the so-called multi-directional input device is a device that is used in remote controllers of various electronic equipment, mobile phones, etc., and obtains different signals according to the tilt angle of the operating body.

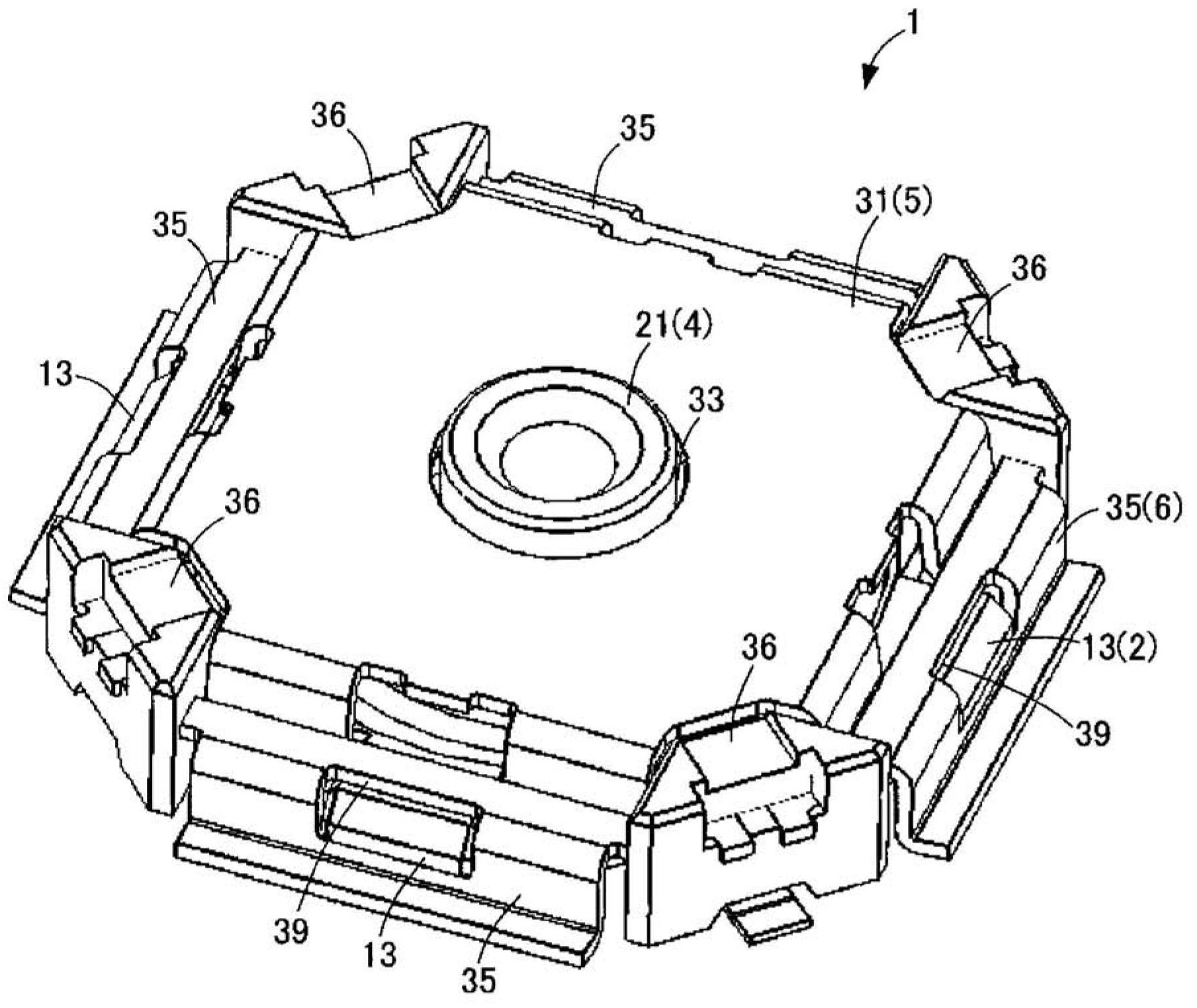

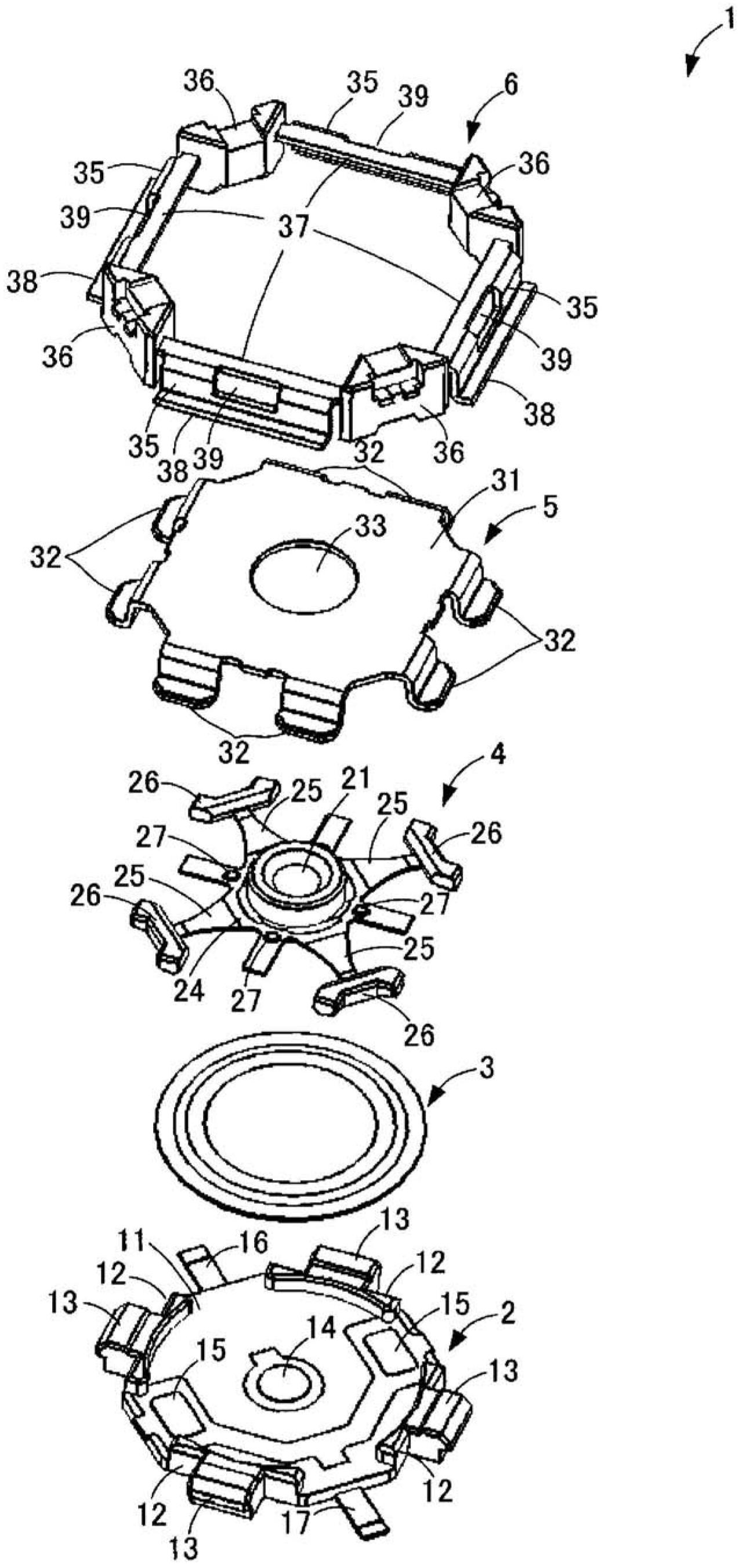

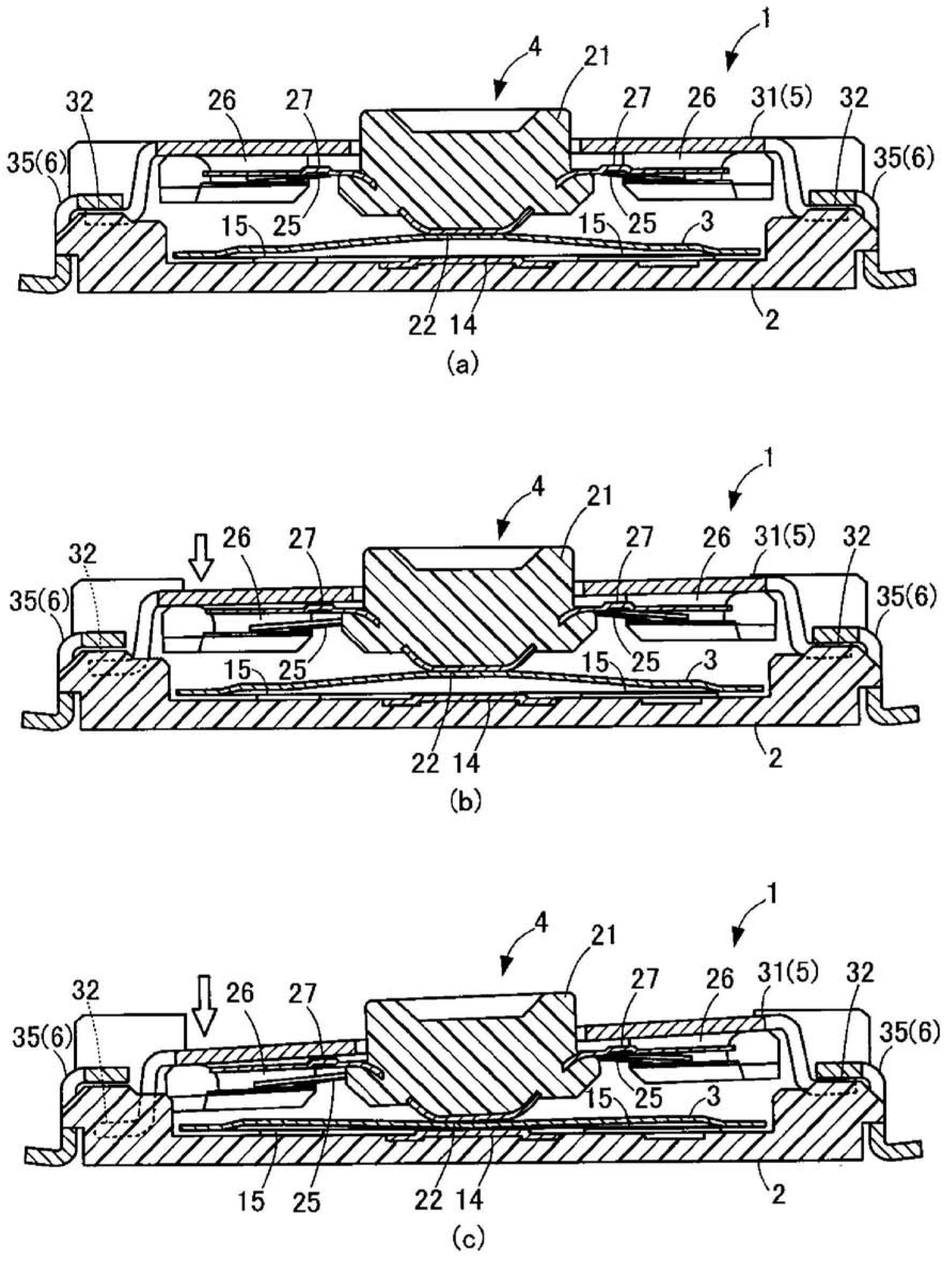

[0041] Reference figure 1 and figure 2 The overall structure of the multi-directional input device using the protrusion forming member of the present invention will be described. figure 1 It is an overall perspective view of the multi-directional input device according to the embodiment of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com