Magnetic valve and driver assistance device having such a magnetic valve

A technology for driver assistance and solenoid valves, which is applied in the direction of valve operation/release devices, valve devices, valve lifts, etc., can solve the problems of reduced durability of solenoid valves, and achieve the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

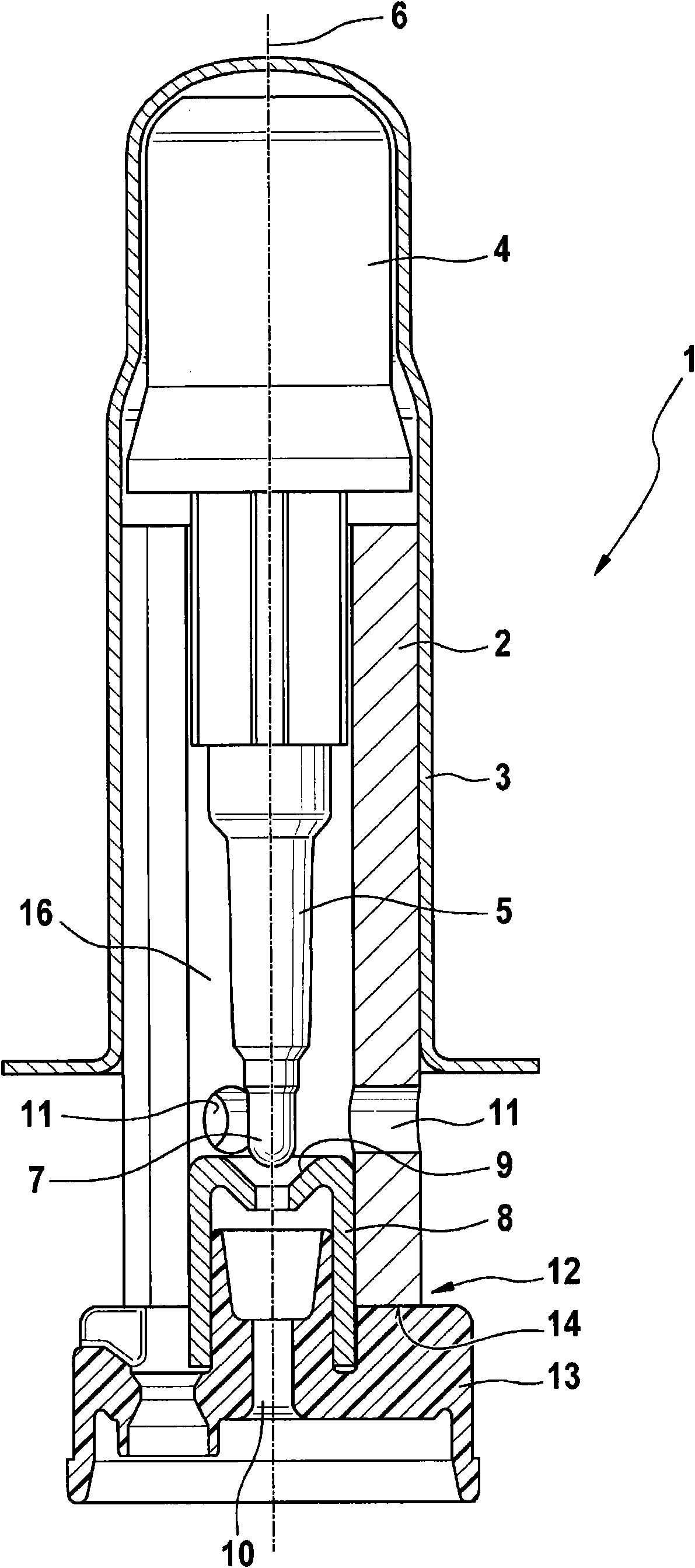

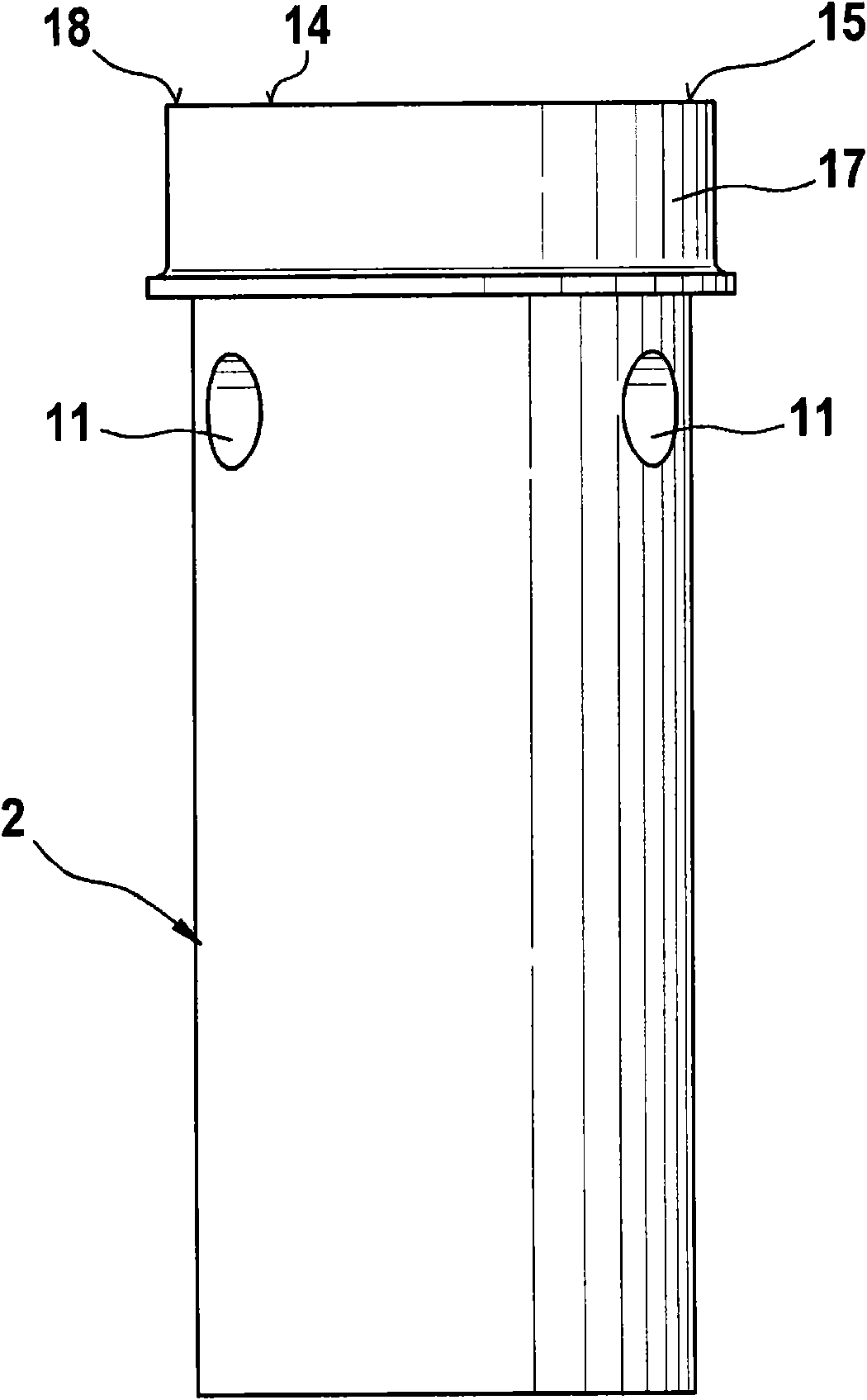

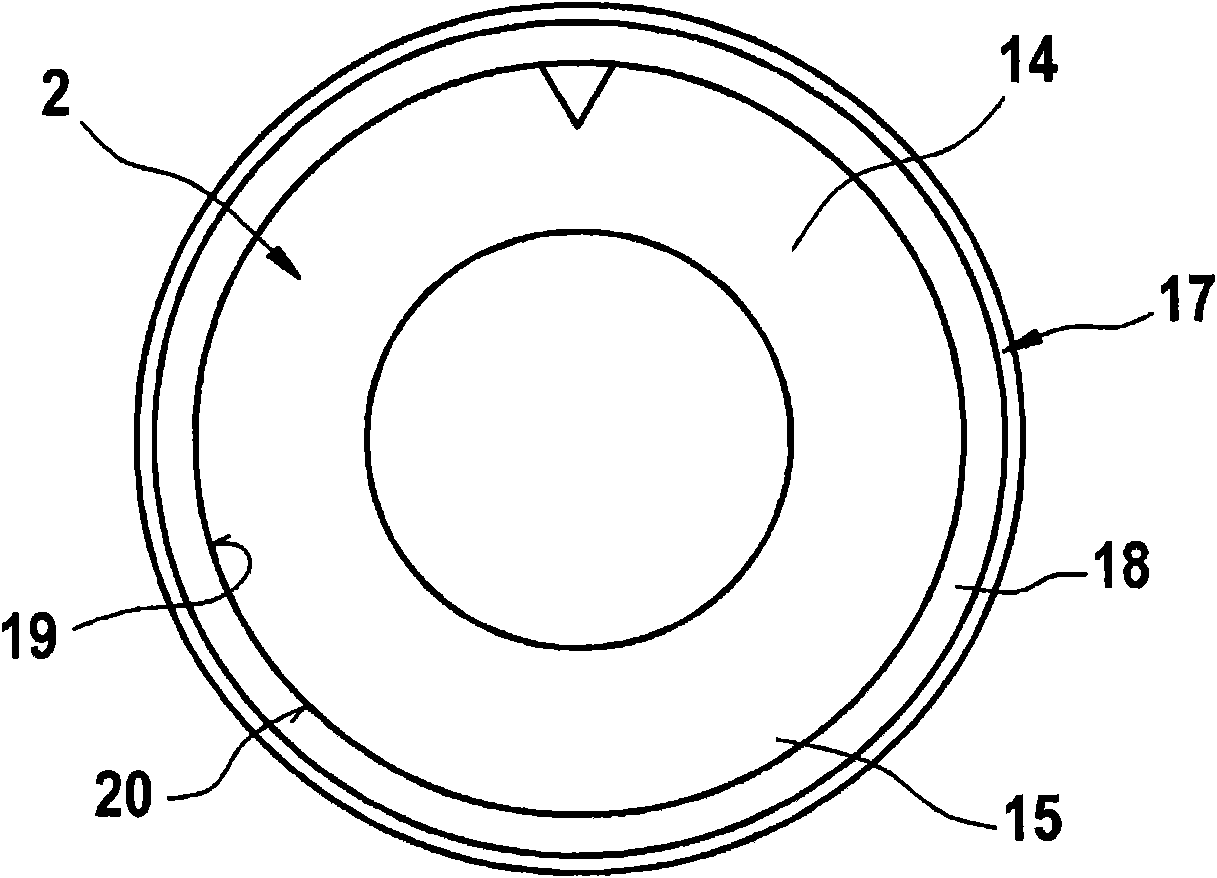

[0018] figure 1 A cutaway side view of a solenoid valve 1 is shown, which are known from the prior art in the embodiment shown here. The solenoid valve comprises a base body 2 which is also referred to as a valve insert. The base body 2 is at least partially surrounded by a housing 3 . In the base body 2 , a magnetic armature 4 and an actuating element 5 connected thereto are mounted axially movable relative to a longitudinal axis 6 of the solenoid valve 1 . The actuating element 5 has a sealing element 7 on its side facing away from the magnetic armature 4, which cooperates with a valve seat 9 formed in the sealing body 8 to establish or disconnect the first fluid connection 10 to the second fluid connection. Fluid connection of a fluid connection 11 , the first fluid connection being designed as an inlet connection and the second fluid connection being an outlet connection.

[0019] The closing element 13 is connected to the main body in an end region 12 of the main body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com