Methods to estimate downhole drilling vibration indices from surface measurement

A surface and index technology, applied in drilling measurement, drilling automatic control system, drilling equipment, etc., can solve problems such as inability to diagnose, estimate and indicate downhole functional failures in real time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In the following detailed description, specific aspects and features of the claimed subject matter are described in conjunction with a number of exemplary methods and embodiments. In this sense, however, the following descriptions are by way of illustration only, and are intended to provide a concise description of exemplary embodiments only, as they are detailed descriptions of particular embodiments or specific uses of the current technology. Furthermore, where a particular aspect or feature is described in connection with a particular embodiment, this aspect or feature can be found and / or implemented, if appropriate, in other embodiments of the invention. Therefore, the claimed invention is not limited to the specific embodiments described below, but the invention includes all alternatives, modifications and equivalents falling within the scope of the figures and claimed subject matter.

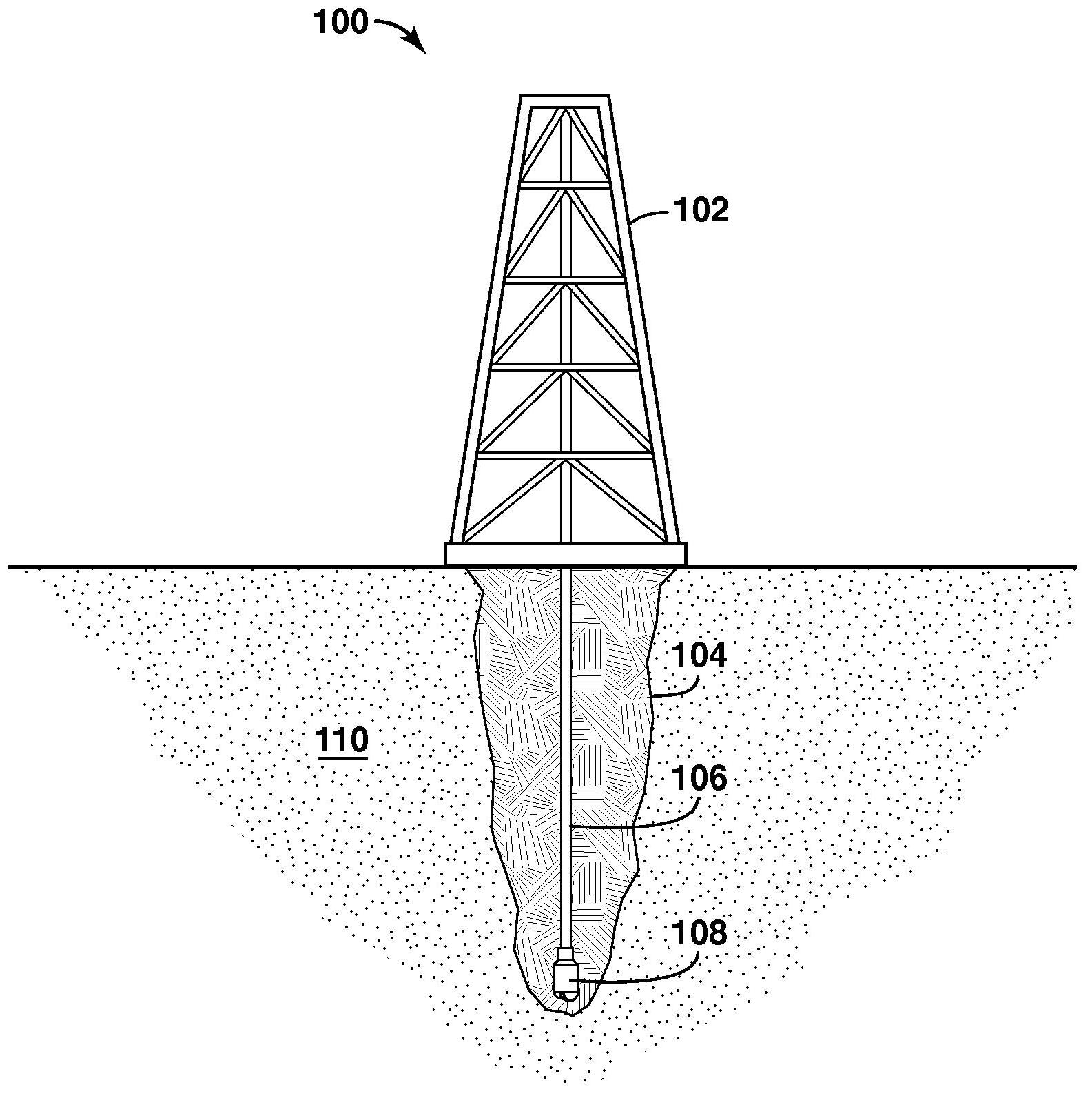

[0047] figure 1 A side view of a relatively common drilling operation at a dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com