Light fixture handle assembly device

A technology for assembling devices and handles, which is applied in the field of lighting, can solve the problems of unstable manufacturing process, lack of consistency in the assembly position of lamp handles, and low production efficiency, and achieve the effect of facilitating production, assembly and manufacturing, facilitating production, assembly and manufacturing, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

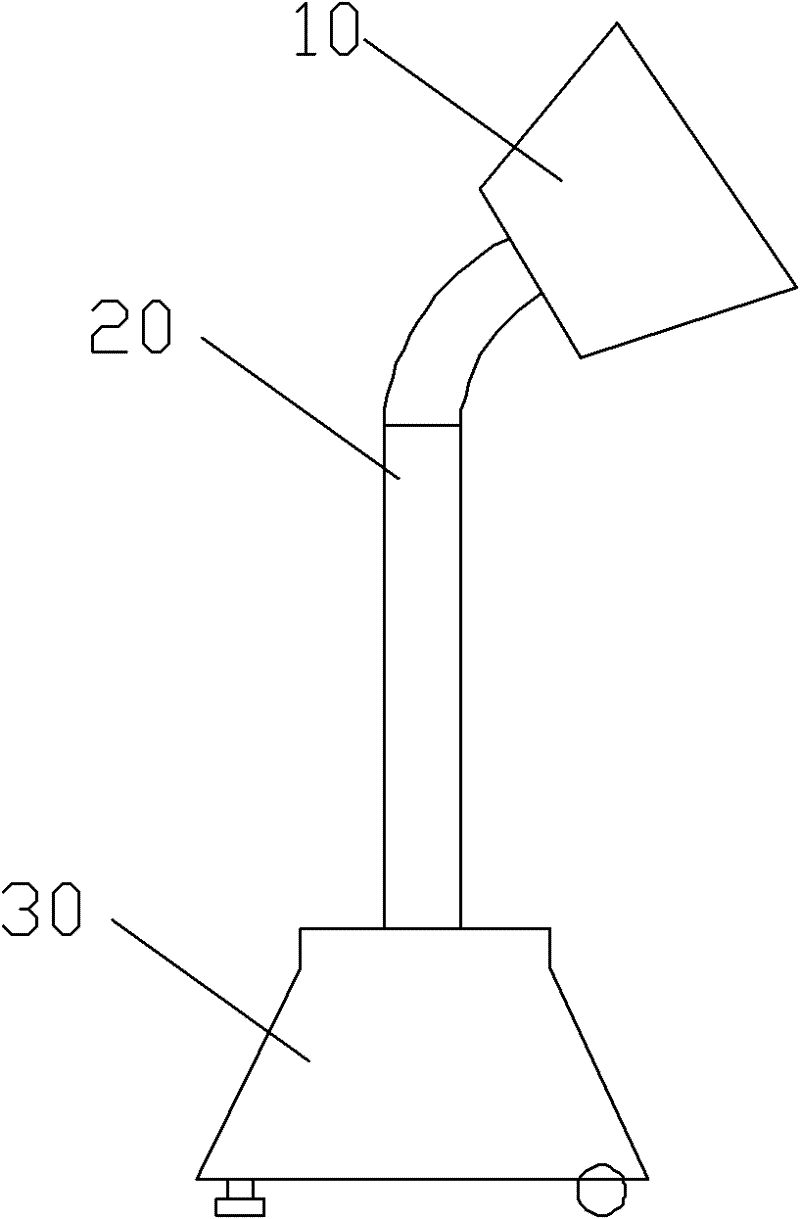

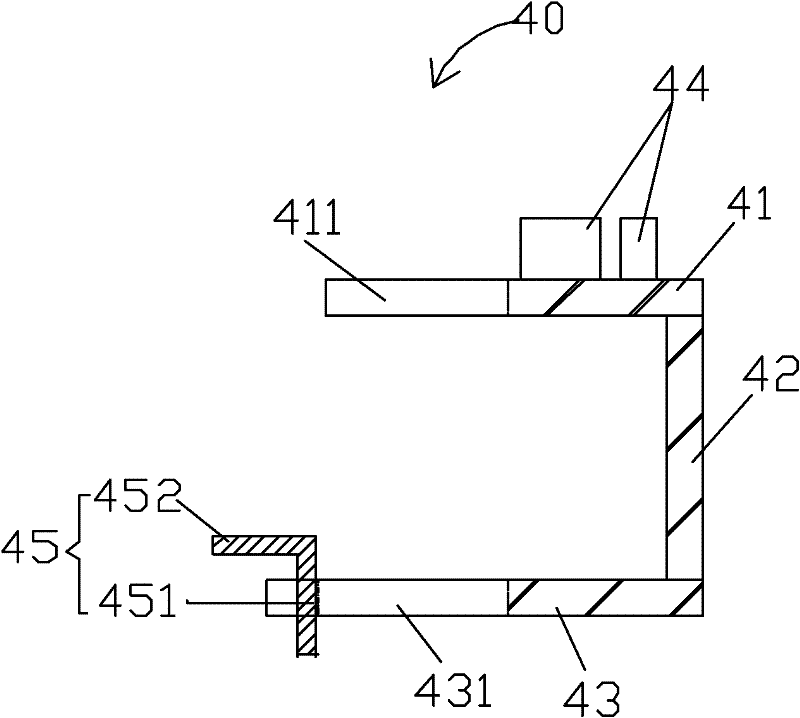

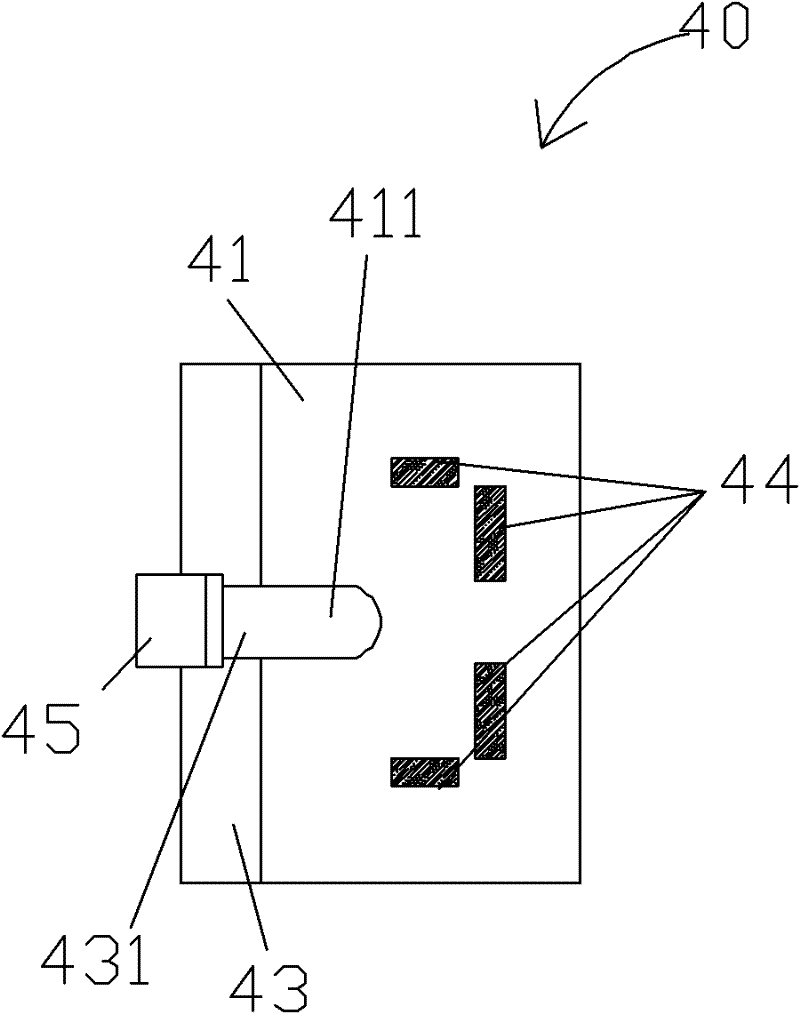

[0027] The lamp handle assembly device structure of the preferred embodiment of the present invention is as follows: figure 2 As shown, the lamp handle 50 is used to install the lamp handle 50 on the lamp pole 20 of the lamp. The lamp handle 50 includes a gripping part 52 that is easy to hold and a connecting part 51 for connecting the lamp pole 20. The structure of the lamp can refer to the attached figure 1 , the structure of lamp handle 50 can refer to the attached Figure 5 . like figure 2 As shown, the lamp handle assembly device 40 includes an upper support plate 41 and a lower support plate 43 arranged in parallel, and a connecting plate 42 connecting the upper support plate 41 and the lower support plate 43 . A positioning block group 44 is provided on the upper surface of the upper support plate 41 for abutting against the outer surface of the gripping portion 52 of the lamp handle 50 to position the lamp handle 50 . The edge of the upper support plate 41 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com