Electronic ballast of electrodeless lamp

An electronic ballast and electrodeless lamp technology, applied in electric light sources, electrical components, lighting devices, etc., can solve the problems of poor circuit reliability and many solder joints, and achieve the effect of small deviation range, stable frequency, and avoidance of burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

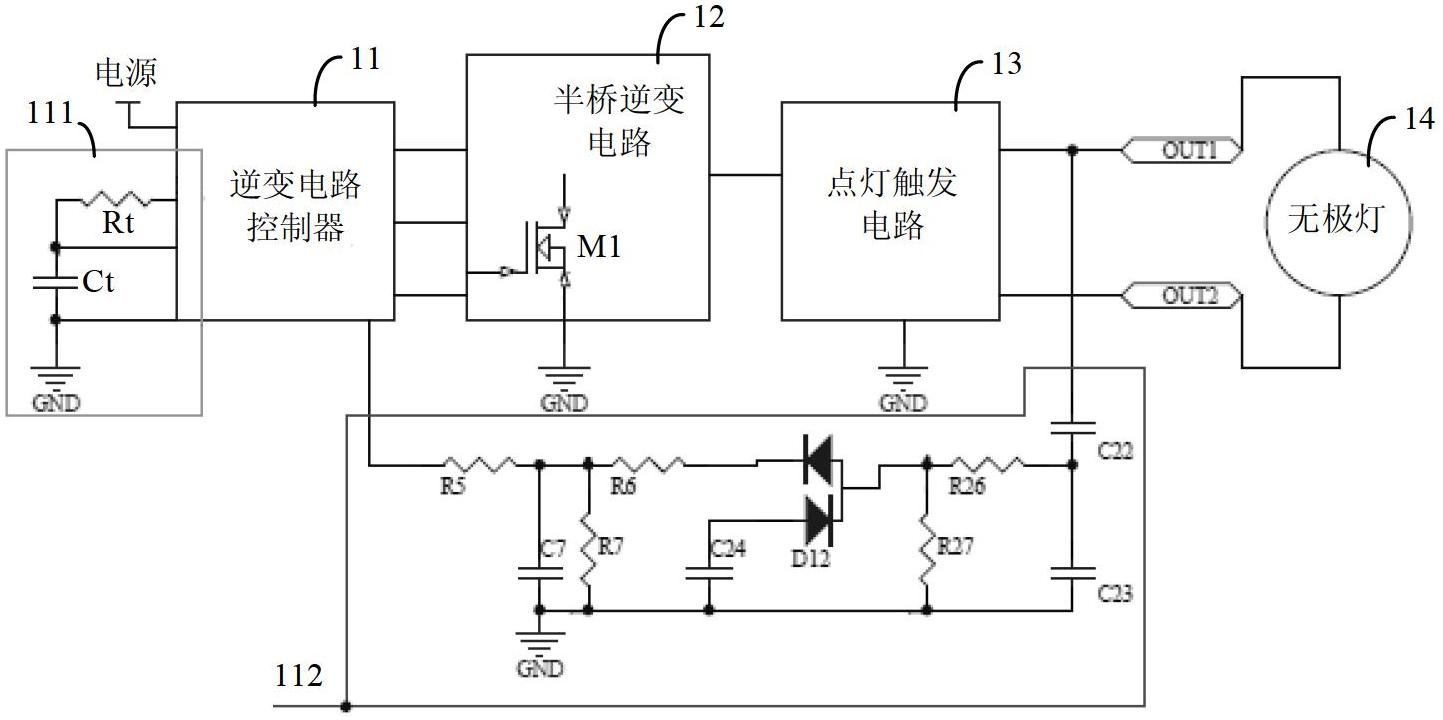

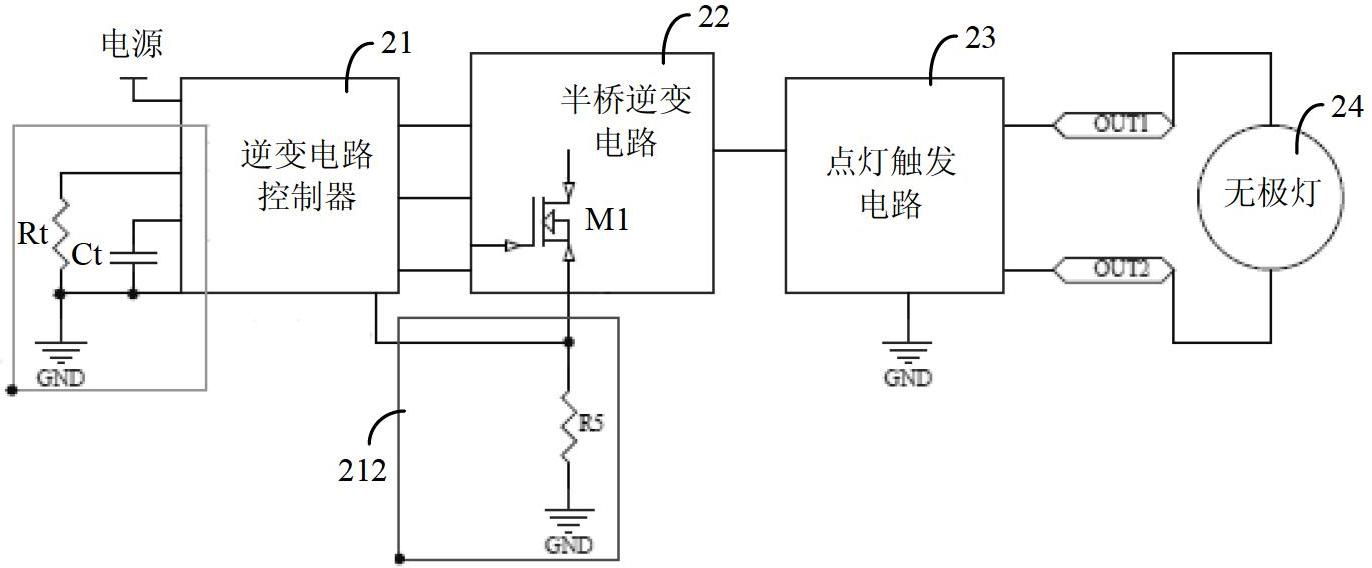

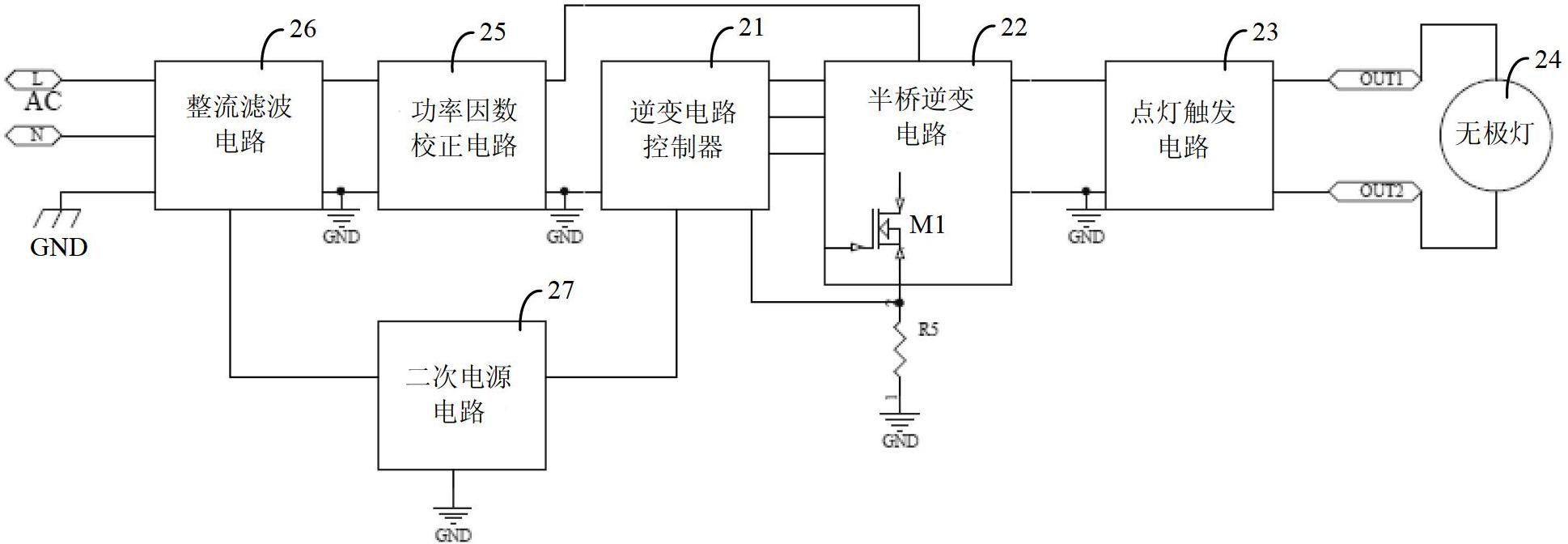

[0021] Electronic ballasts for electrodeless lamps in the prior art usually use inverter circuit controllers used in electronic ballasts for ordinary energy-saving lamps, such as IR2156S chips, which are easy to burn out. After research, the inventor found that the reason is mainly due to the low frequency of the output signal of the inverter circuit controller used in the electronic ballast of ordinary energy-saving lamps, which is usually lower than the working frequency of the electrodeless lamp. For example, the working frequency of common energy-saving lamps in the market is only 20KHz ~ 60KHz. Using the inverter circuit controller in the electronic ballast of energy-saving lamps to construct the electronic ballast for electrodeless lamps will cause the output signal frequency of the inverter circuit controller to be reduced. Forcibly increasing to hundreds of KHz, which is much higher than the design specification frequency, increases the risk of burning the inverter circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com