Metering method of particle counter

A particle counter and measurement method technology, applied in the field of measurement, can solve the problems of difficult measurement result consistency, inability to meet application requirements, difficult to improve reliability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

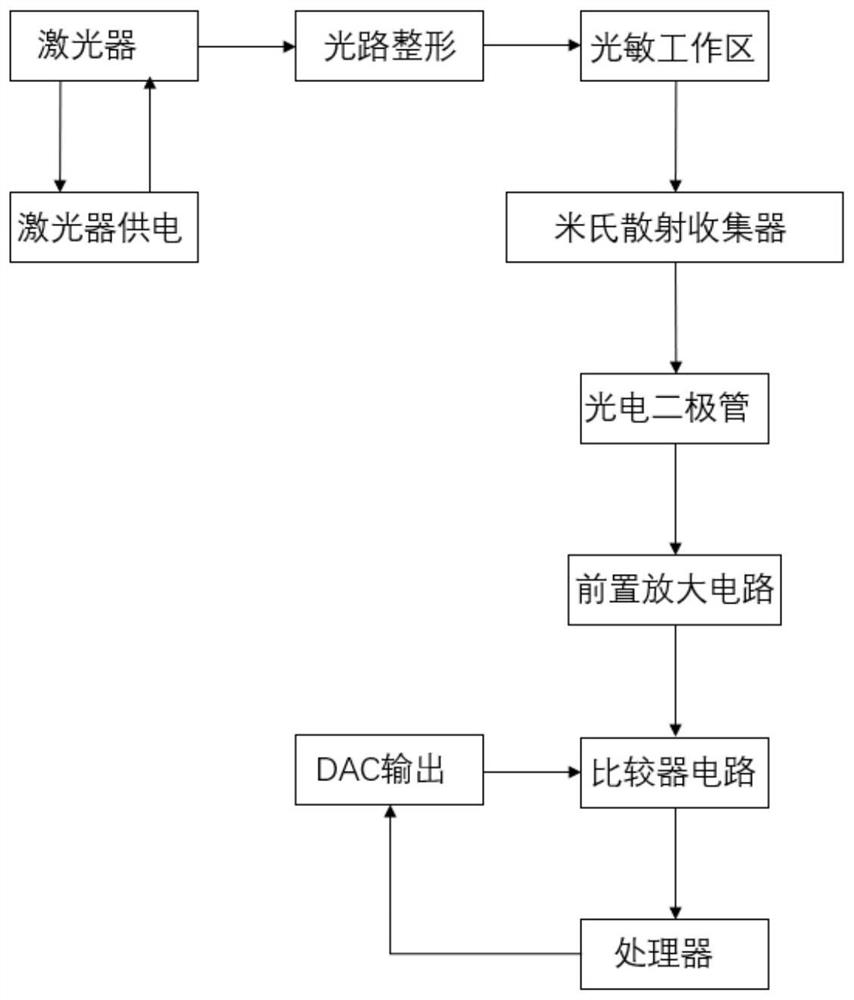

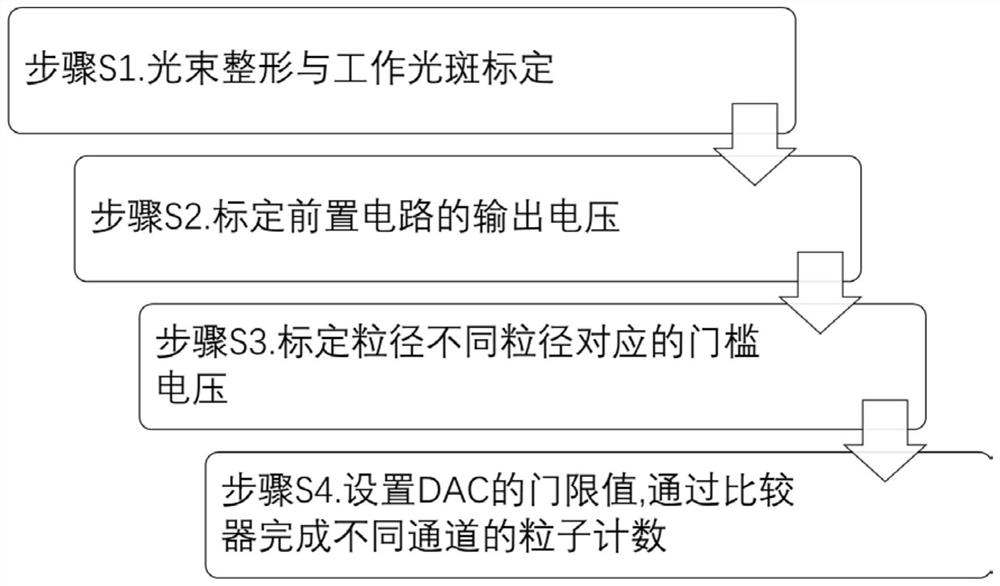

Embodiment 1

[0037] In Embodiment 1 of the present invention, as figure 1 As shown, the particle counter in this embodiment is composed of an optical module providing a working light beam, a working area for detection, a photoelectric receiving module for receiving and converting optical signals, a processor, a comparator and a DAC. The working area is the photosensitive working area and the Mie scattering collector. The optical module includes a laser as a laser light source and its power supply components. By adjusting the power supply of the laser, the output light intensity of the laser can be adjusted. In this embodiment, the airflow of a certain concentration of particles passes through the light field of the photosensitive working area, and the light emitted by a single particle after passing through the Mie scattering collector is collected by the photoelectric receiving module and projected onto the photosensitive element of the photoelectric receiving module . The photosensitiv...

Embodiment 2

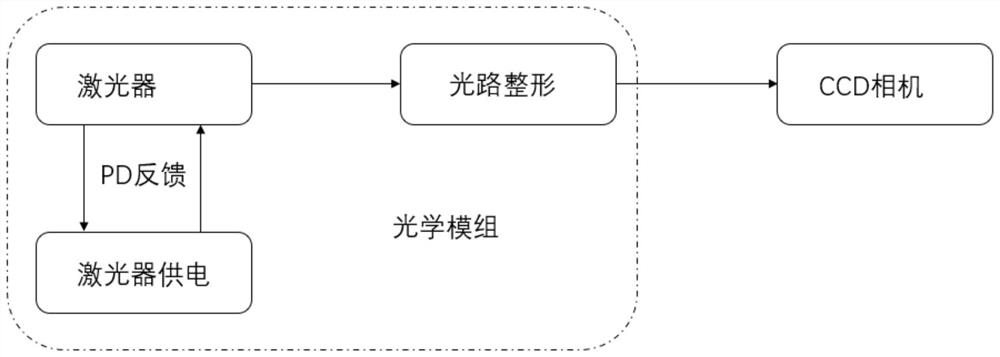

[0043] Because the light intensity of the particle counter is required to be uniform, and the light intensity at each point in the entire working area is the same, it is required that the light intensity of the optical module of each particle counter has better consistency. Such as Figure 5 As shown, the difference between Embodiment 2 and Embodiment 1 is that an optical power meter is used in addition to a CCD camera when calibrating the spot. In step S1, the light intensity of the working beam required by the actual application is also used. The light intensity is equal to the unit The optical power of the area, thereby preset the standard total value of the optical power of the working area, measure the optical power of the working beam, and adjust the optical power of the working area to be consistent with the standard total value based on the measurement results, thereby calibrating the optical power of the working beam powerful. In this embodiment, multiple particle co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com