Slide rail tool free mounting frame for server

A mounting bracket, tool-free technology, applied in the direction of support structure installation, rack/frame structure, etc., can solve the problems of low work efficiency, inconvenient installation work, etc., and achieve the effect of convenient operation, simple structure, and tool-free installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

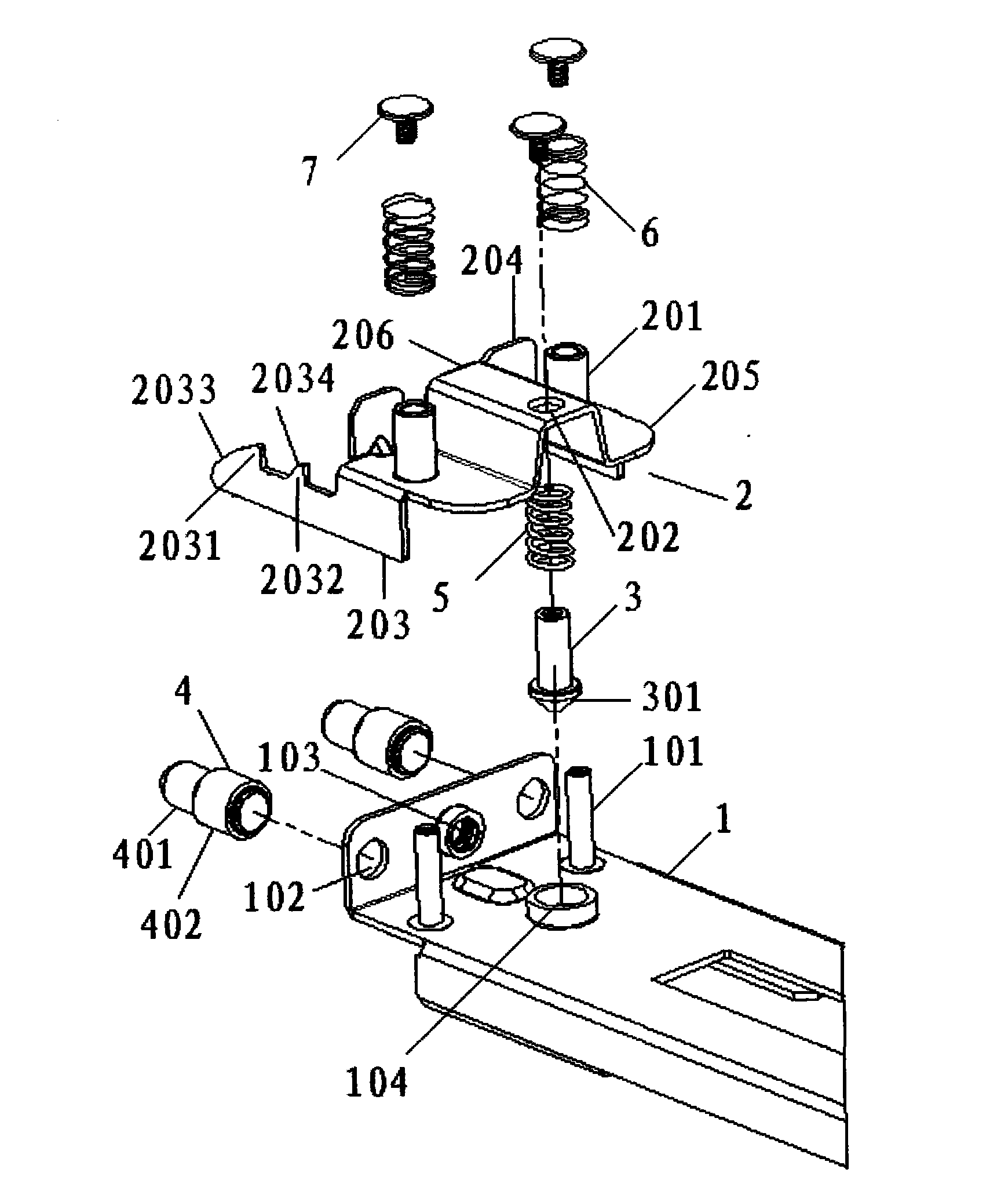

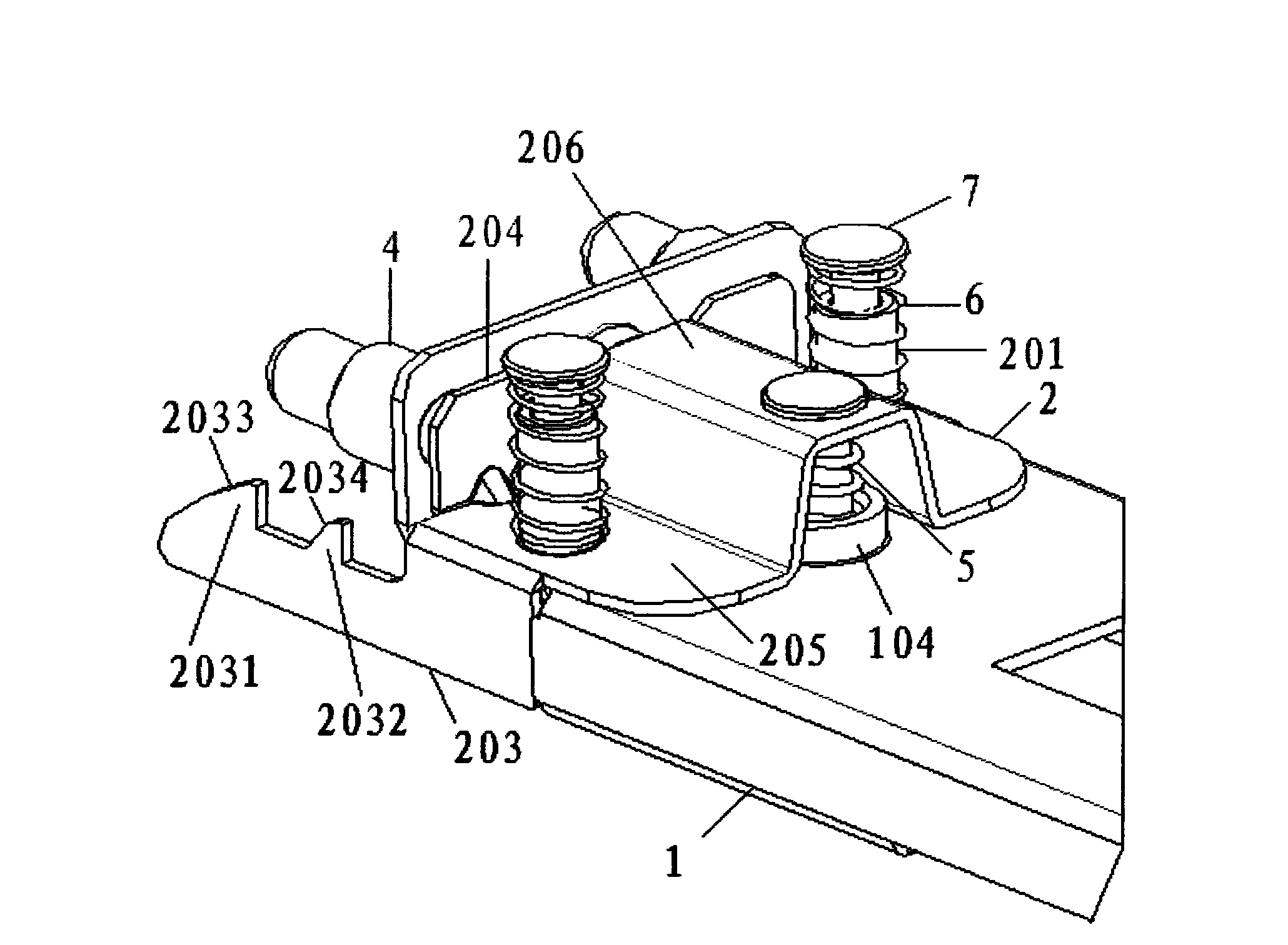

[0042] The following is attached image 3 , 4 , 5 and 6 are described in detail to the present embodiment:

[0043] see image 3 with Figure 4 As shown, the rack installation hole 801 on the rack 8 is a square hole of 9.5mm*9.5mm, and the diameter of the square hole can accommodate the second positioning cylinder 402 .

[0044] The distance between the two rack positioning columns 4 of the tool-free mounting bracket for server slide rails in this embodiment can ensure that the two rack positioning columns 4 fall into different positions on the rack 8 for rack installation. In the hole 801, when installing, align the frame positioning column 4 with the frame mounting hole 801, and then push it forward. During the process of pushing, the vertical plate of the frame 8 will first touch the The first hook tooth 2031, due to the setting of the slope 2033, the frame lifting hook 2 will be pushed up, when the vertical plate of the frame 8 passes over the first hook tooth 2031, du...

Embodiment 2

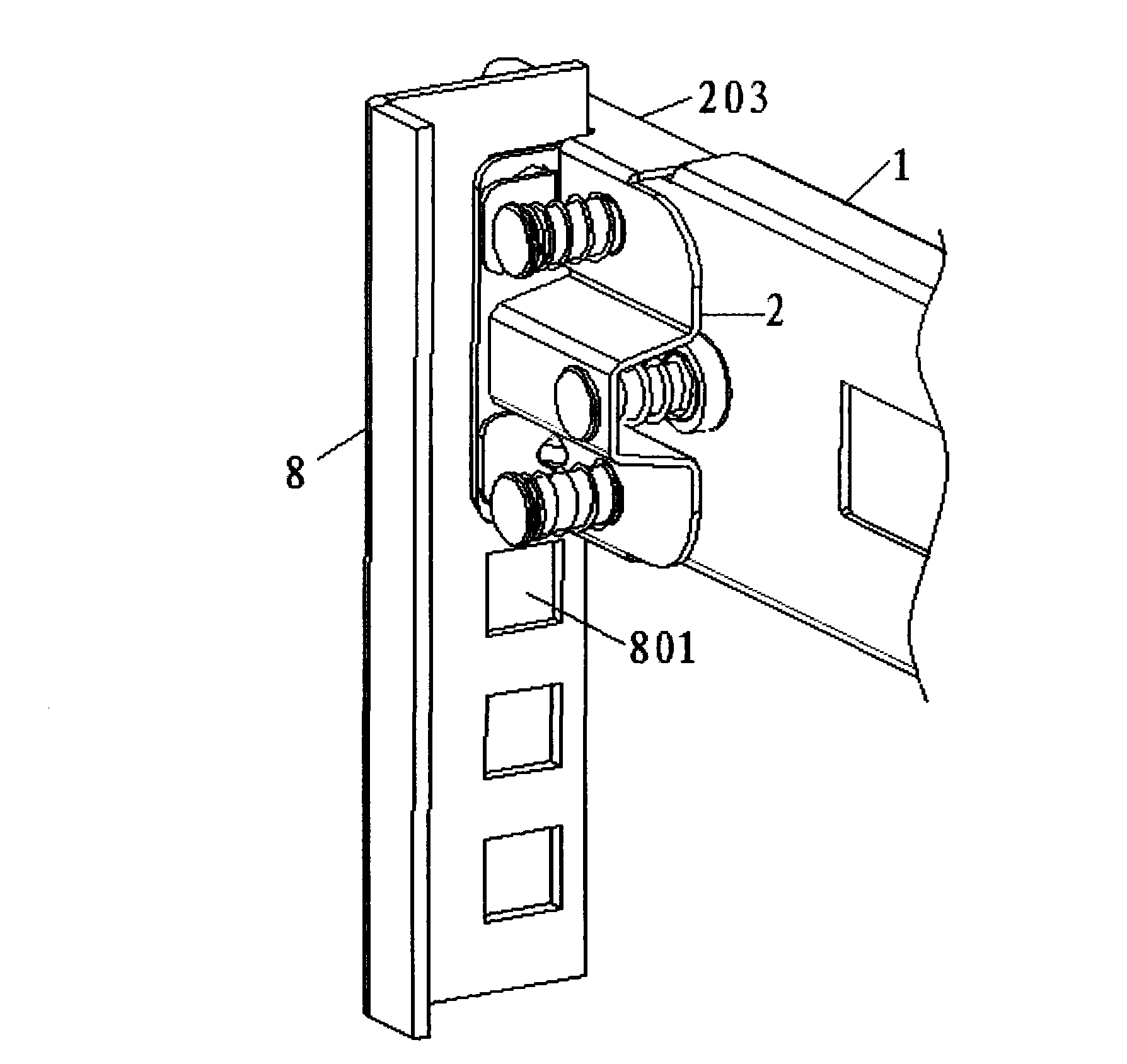

[0049] The following is attached Figure 7 with Figure 8 The present embodiment is described in detail:

[0050] see Figure 7 with Figure 8 As shown, the rack mounting hole 801 on the rack 8 is a round hole with a diameter of 7.2 mm, and the size of the round hole can accommodate the first positioning cylinder 401 .

[0051] The distance between the two rack positioning columns 4 of the tool-free mounting bracket for server slide rails in this embodiment can ensure that the two rack positioning columns 4 fall into different positions on the rack 8 for rack installation. In the hole 801, the installation process is the same as the installation process in Embodiment 1. Since the rack installation hole 801 can only accommodate the first positioning column 401, the vertical plate of the rack 8 will be formed by the first positioning column 401. A hook tooth 2031 bites.

[0052] When the server slide rail tool-free installation bracket of this embodiment needs to be disasse...

Embodiment 3

[0054] The following is attached Figure 9 with Figure 10 The present embodiment is described in detail:

[0055] see Figure 9 with Figure 10 As shown, the rack installation hole 801 on the rack 8 is a threaded hole of M5-M6, and the diameter of the threaded hole is smaller than the diameter of the first positioning cylinder 401 .

[0056] The distance between the two rack positioning posts 4 of the tool-free mounting bracket for the server slide rail in this embodiment can ensure that the two rack positioning posts 4 are in the rack mounting holes at different positions on the rack 8 801.

[0057] When installing the server slide rail tool-free mounting bracket of this embodiment on the rack 8, it is necessary to use fixing screws 9. During operation, align the rack positioning posts 4 with the rack mounting holes 801 , since the end face of the first positioning cylinder 401 is provided with a screw hole, the fixing screw 9 can be screwed into the frame mounting hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com