A packaging for use in vacuum packaging

A technology of vacuum packaging and packaging bags, which is applied in household packaging, packaging under vacuum/special atmosphere, packaging, etc., which can solve the problems of high production cost of packaging bags and no improvement in the anti-puncture performance of packaging bags.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] It should not be difficult for a professional to realize that the present invention, in addition to its own characteristics, achieves the above-mentioned objects and advantages. The embodiment described here is not intended to limit the scope of the inventive solutions.

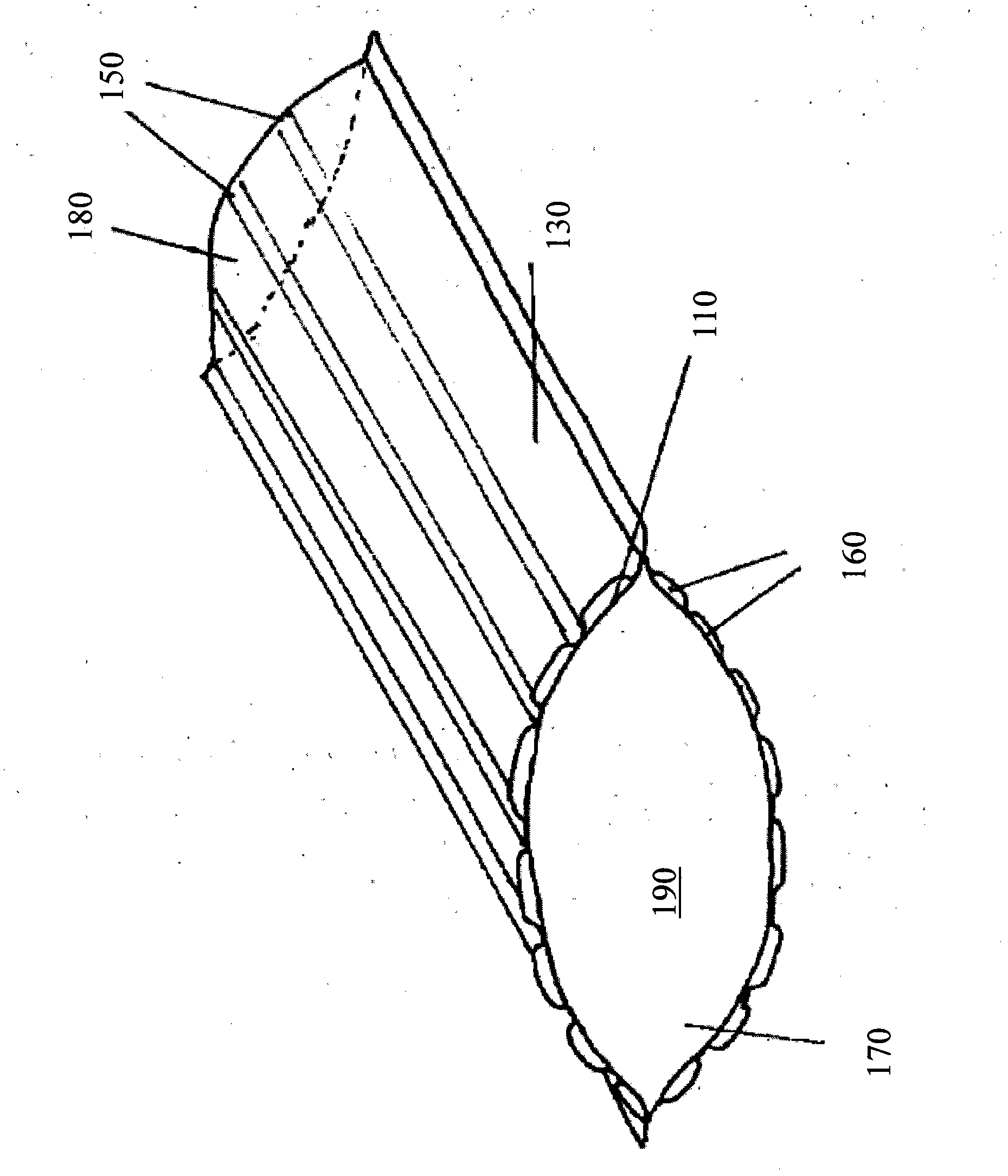

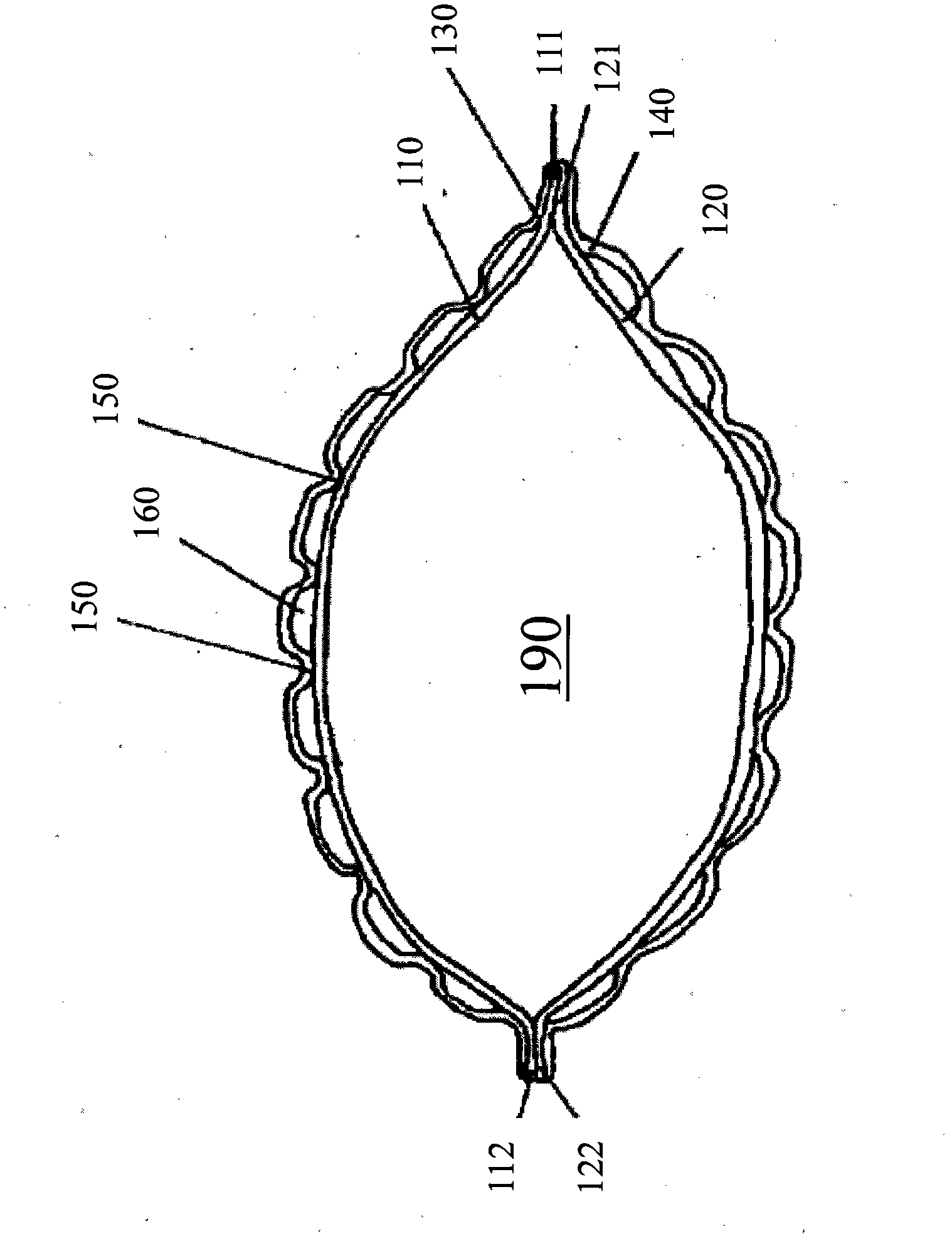

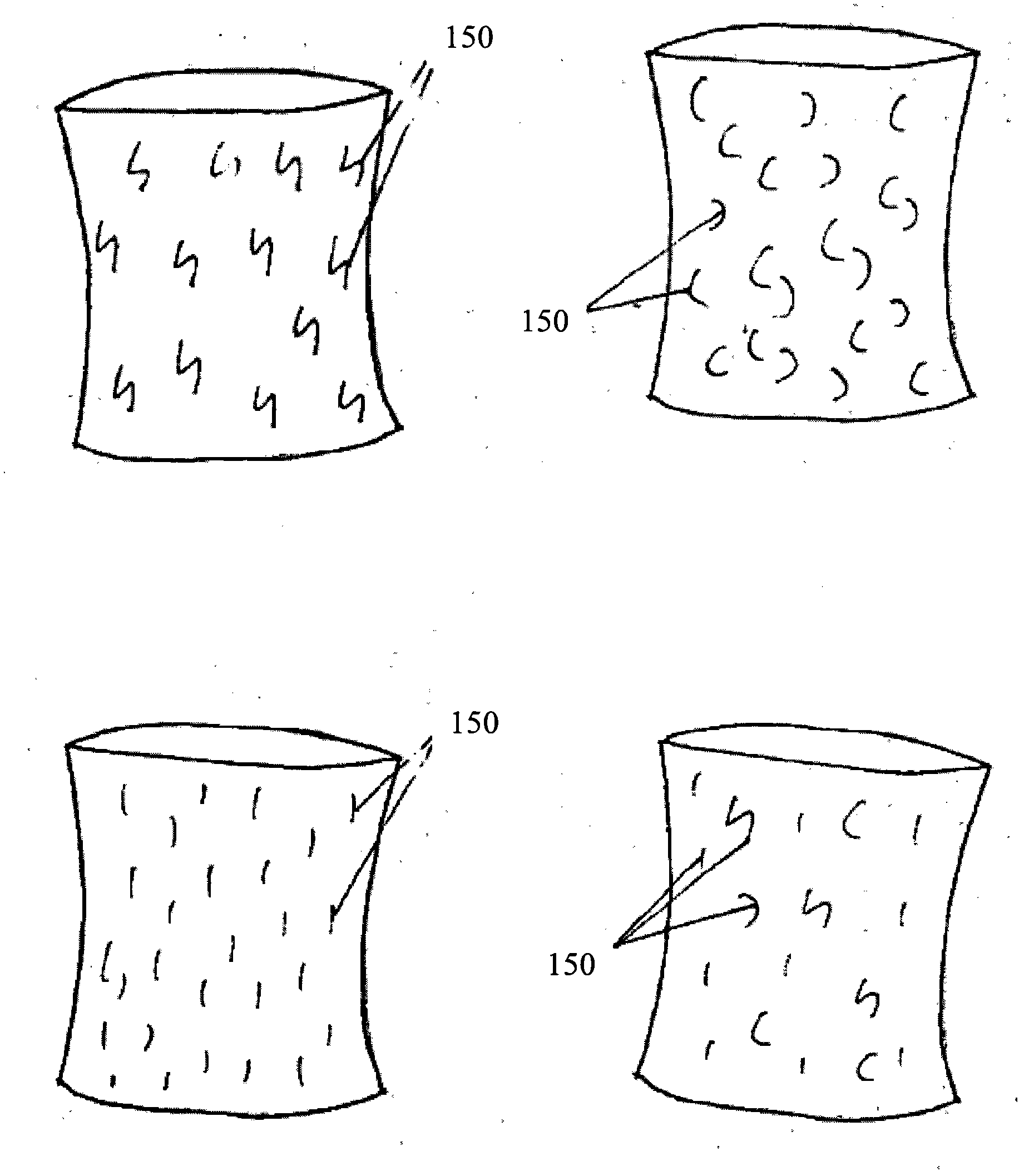

[0017] The present invention comprises a packaging bag (100) for use in a vacuum packaging process comprising first (110) and second planar compartments (120) sealed together along opposite outer edges on both sides to form a the inner space (190); the third (130) and the fourth plane interlayer (140) are overlapped on the opposite two outer edges of the first (110) and the second plane interlayer (120) and sealed to form a packaging bag (100 ) of the puncture-resistant outer surface; the top (170) and bottom openings (180) for communicating with the interior space (190) are formed by the unsealed portion of the partition edge; it is characterized in that the third (130) and the second The four compar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com