Quick positioning device of connecting shaft in cover plate shaft sleeve

A technology of positioning device and connecting shaft, which is applied to the seat or cover of toilet, household utensils, sanitary equipment and other directions, can solve the problems of time-consuming and laborious, inconvenient disassembly or installation, low assembly efficiency, etc., and achieves simple positioning and connection structure, The positioning connection and disassembly and separation are convenient and reliable, and the manufacturing cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] Example one (Locating pin and compression spring constitute a spring pin device).

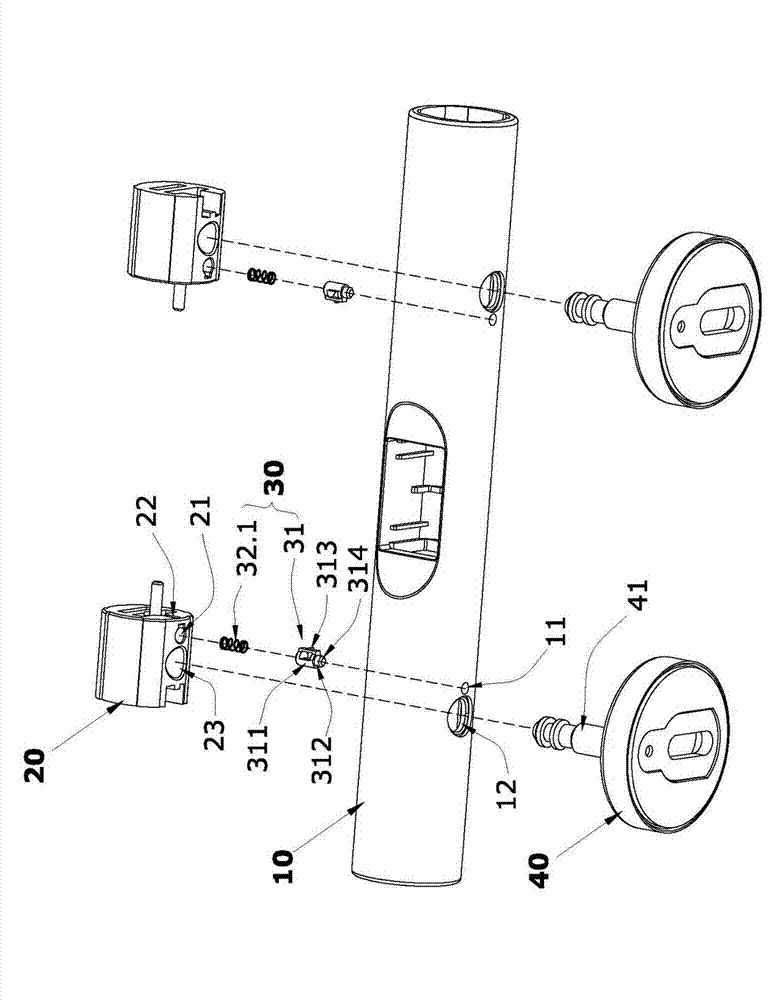

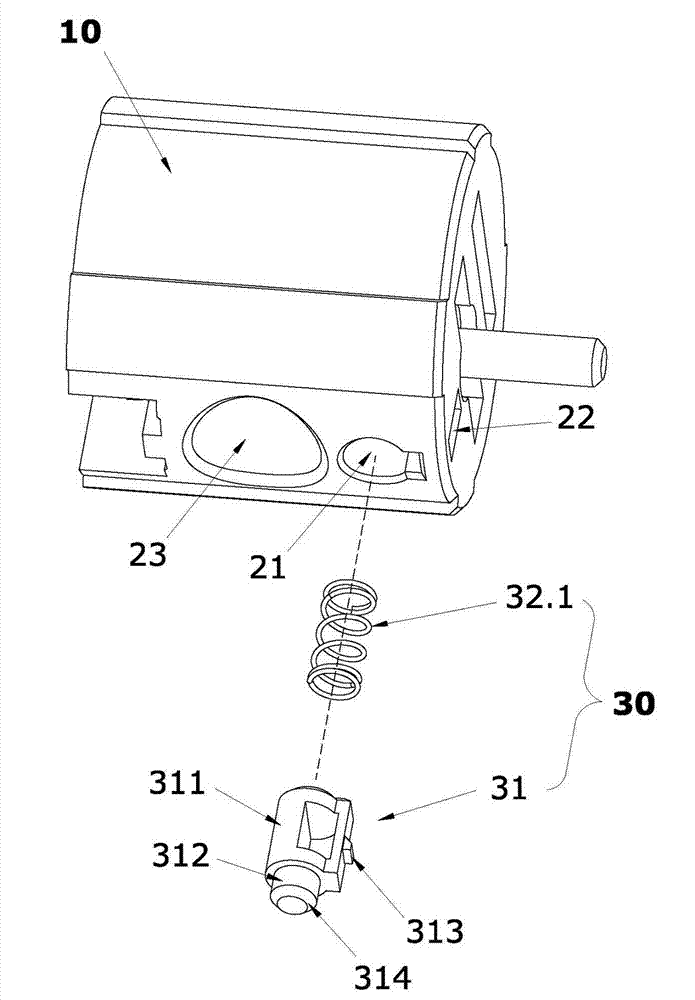

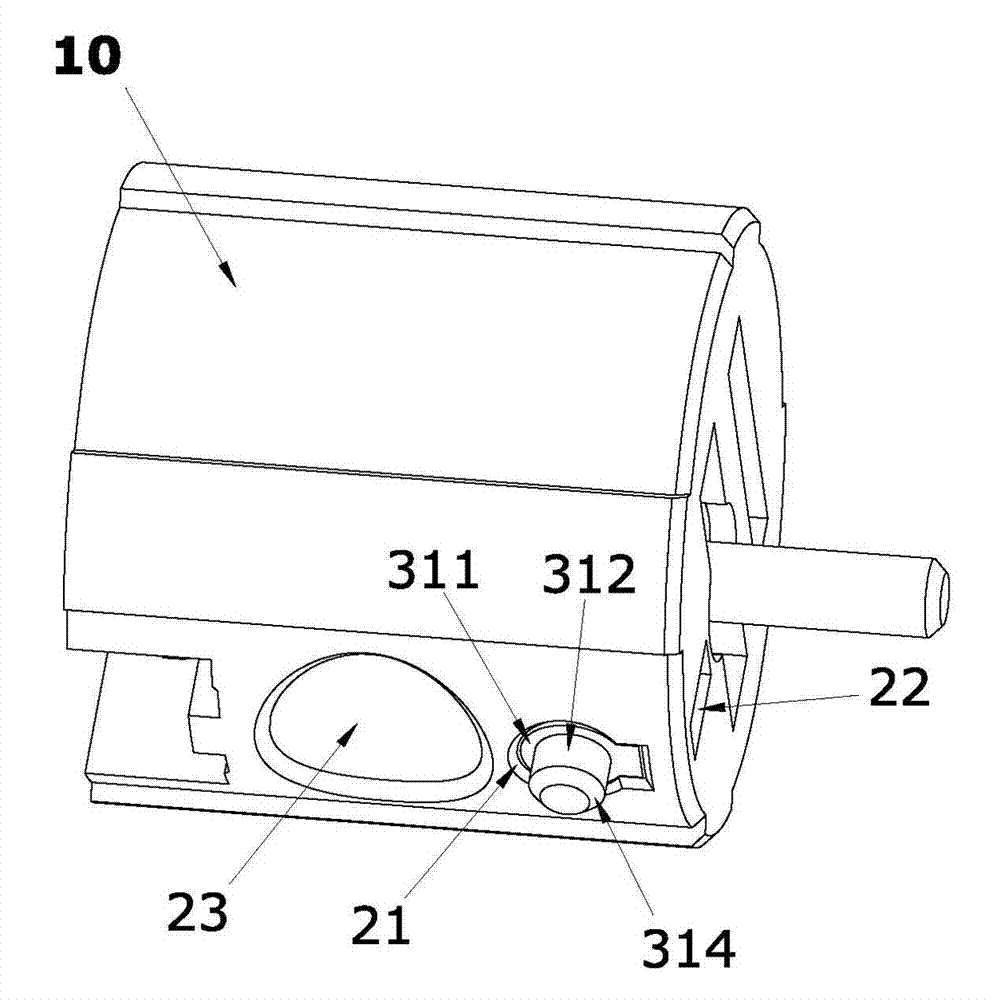

[0029] Such as figure 1 with Figure 4 A quick positioning device for a connecting shaft in a cover shaft sleeve shown includes a cover plate, a shaft sleeve 10 and a connecting shaft 20 that can be axially sleeved in the shaft sleeve 10, and a positioning device is provided in the radial direction of the shaft sleeve 10. Through hole 11, such as figure 2 with image 3 As shown, a mounting hole 21 is provided in the radial direction of the connecting shaft 20, and a spring pin device 30 is provided in the radial direction of the connecting shaft 20; the spring pin device 30 in this embodiment consists of a positioning pin 31 and a positioning pin 31 The pin 31 and the connecting shaft 20 are formed by an elastic member. The positioning pin 31 in this embodiment is formed by integrally forming a sliding post 311 and a plug pin 312. The diameter of the sliding post 311 is larger than the ap...

Example Embodiment

[0033] Example two (The positioning pin and the wave spring are integrally formed to form a spring pin device).

[0034] Such as Figure 5 with Image 6 A quick positioning device for a connecting shaft in a cover plate bushing shown in this embodiment is different from the first embodiment in that the elastic member uses a wave spring 32.2 instead of the compression spring 32.1 in the first embodiment. The wave spring 32.2 and the positioning pin 31 are integrally molded by injection molding, which makes it easier to assemble the spring pin device 30 in the mounting hole of the connecting shaft 20. Other structures, working principles, and specific implementation actions of this embodiment are the same as those in the first embodiment.

Example Embodiment

[0035] Example three (The elastic pin device composed of the positioning pin and the elastic arm is integrated with the connecting shaft).

[0036] Such as Figure 7 with Figure 8 This embodiment shows a quick positioning device for the connecting shaft in the cover plate sleeve. The difference between this embodiment and the first embodiment is that the elastic pin device 30 consists of a positioning pin 31 and a pin connected to the positioning 31 and the connecting shaft The elastic arm 32.3 between 20 is formed, and one end of the elastic arm 32.3 is fixed to the connecting shaft 20, and the other end is fixed to the positioning pin 31. The positioning pin 31, the elastic arm 32.3 and the connecting shaft 20 are integrally formed by injection molding, eliminating the need for installation in the first embodiment. Hole 21, limit sliding hole 22, sliding column 311 and the limit block 313 on its side; insert the connecting shaft 20 with the elastic pin device 30 in the axial d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap