Cutting device and clamping device thereof

A technology of clamping device and cutting equipment, applied in the direction of metal processing, etc., can solve the problems of affecting the quality of finished products, the length of the roll paper 141 is different, and the size cannot be changed, so as to achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

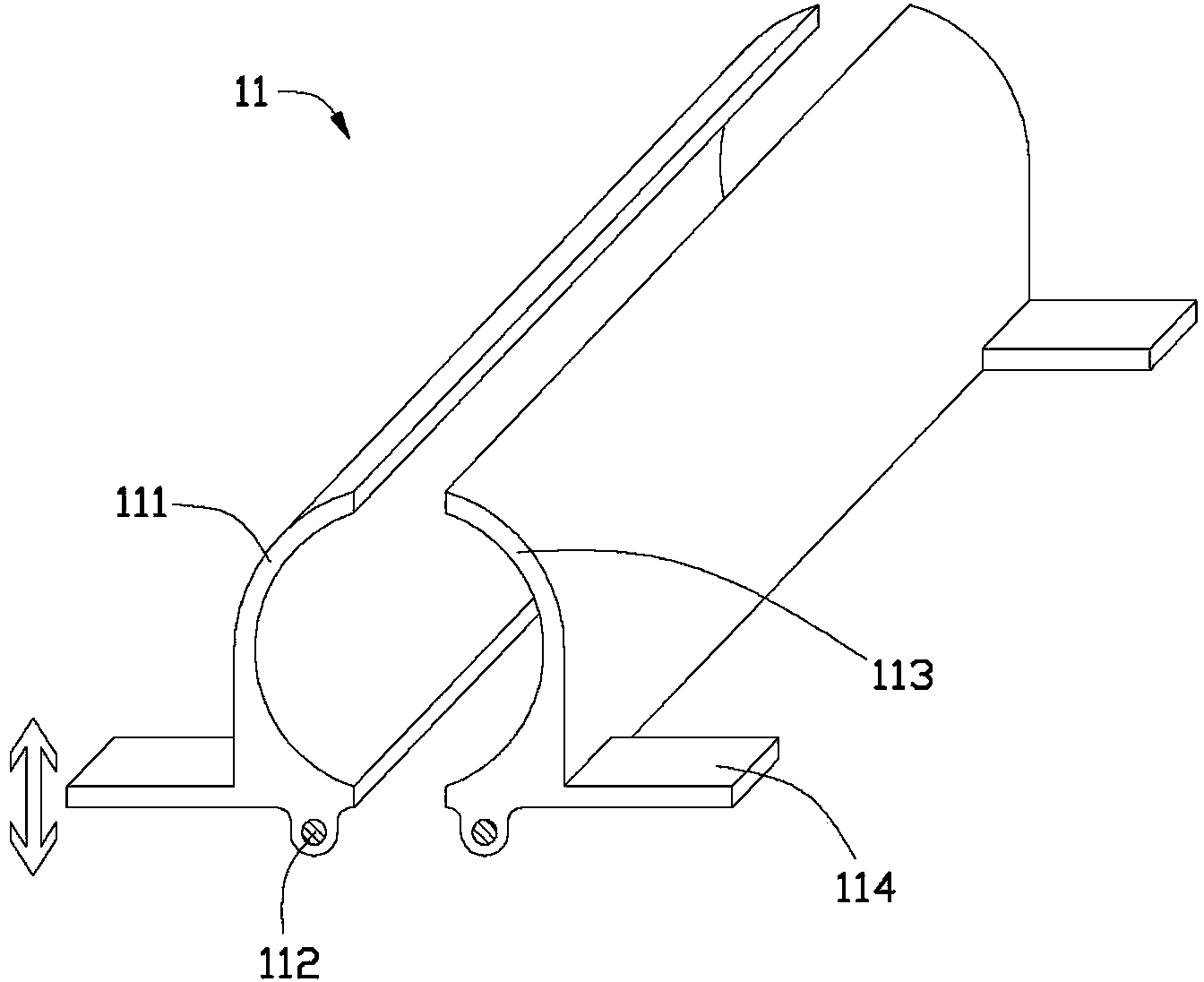

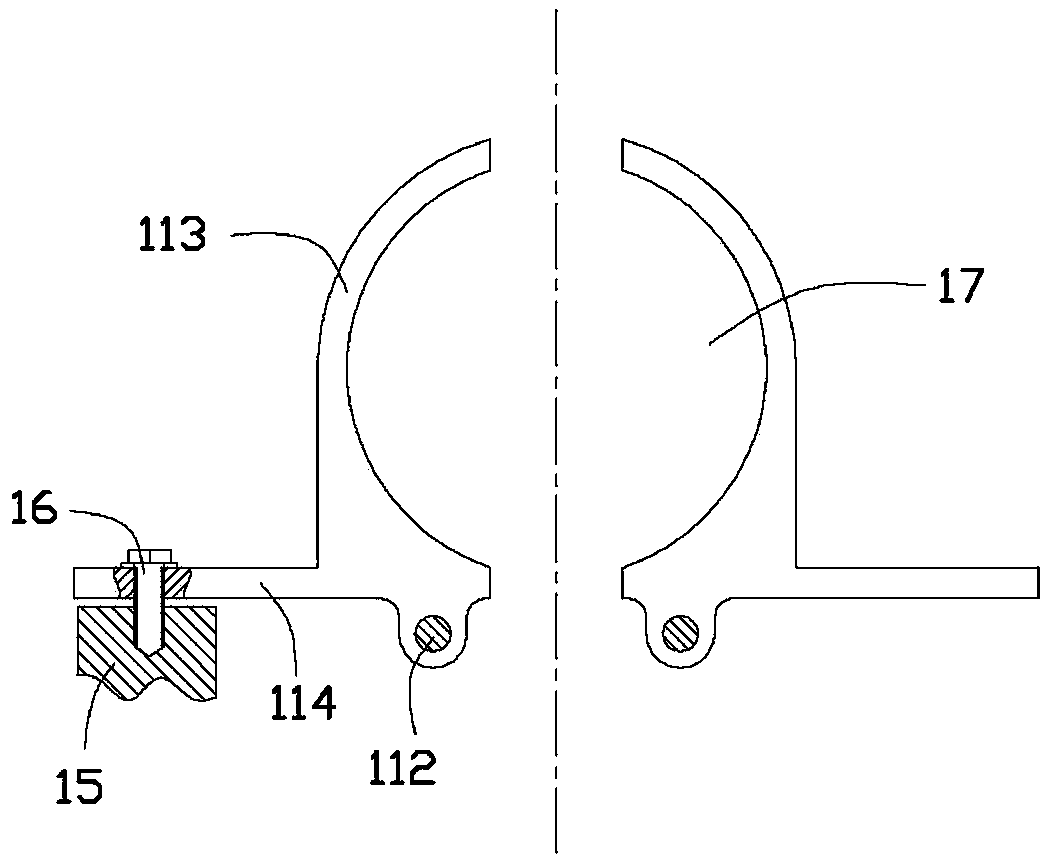

[0021] Please refer to Figure 4 , The clamping device provided by the first embodiment of the present invention includes two clamping arms 30 and two pivots 36 , and the clamping arms 30 are rotatably connected to the pivots 36 .

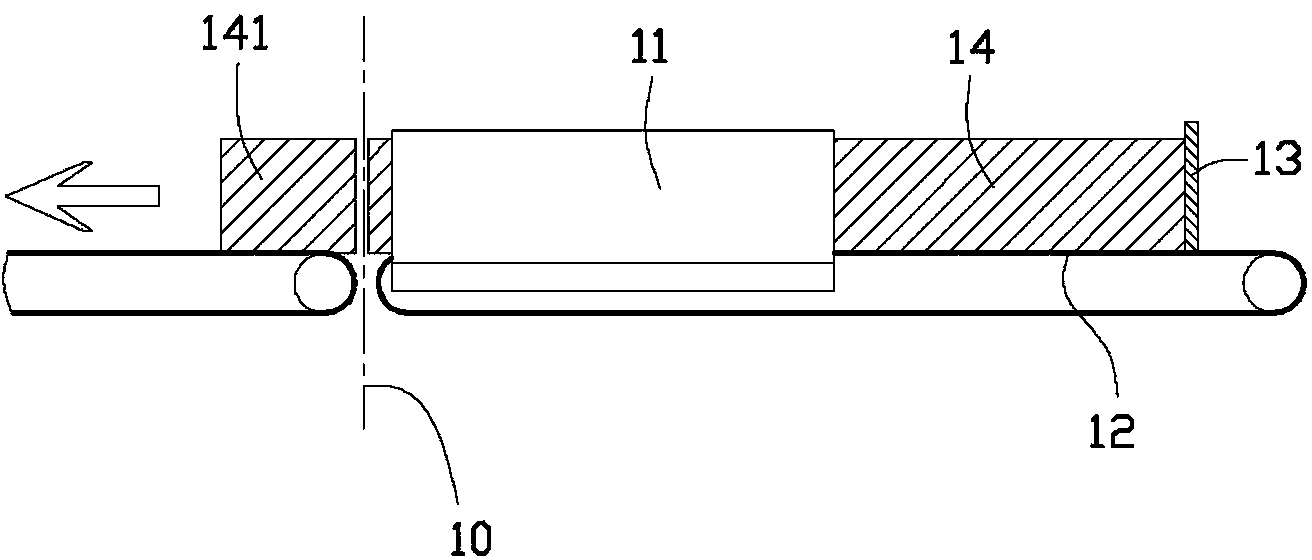

[0022] The clamping device is used in cutting equipment. When the cutting device cuts materials, the clamping device is used to clamp the materials so as to facilitate the completion of the cutting action. The cutting equipment also includes a frame, a conveyor belt, a push plate and a cutter. The push plate is fixed on the conveyor belt, the conveyor belt and the push plate are used to transfer the material to be cut, the cutter is used to cut the material, and the cutter and the conveyor belt are connected with the frame of the cutting device. The push plate is used to assist the conveyor belt to pass the material to be cut. Therefore, in some embodiments, if the conveyor belt has sufficient transmission force, there is no need to set a push p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com