Fall-preventing brake sliding carriage and fall-preventing brake method for hoist bucket of vertical shaft

A technology of anti-falling and hanging buckets, which is applied in the field of guidance and anti-falling of hoisting buckets in construction shafts, and in the field of vertical lifting container guidance and anti-falling. Grasp the lifting of the wire rope and other issues to achieve the effect of avoiding secondary arrest, good anti-falling effect, and improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

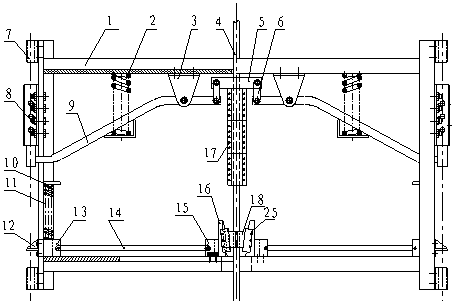

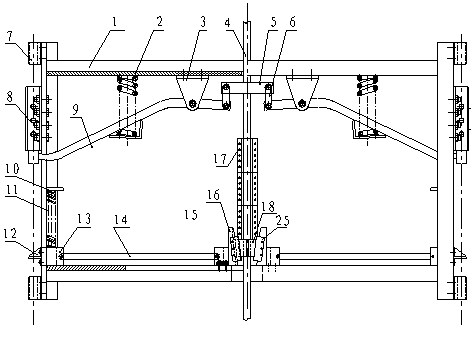

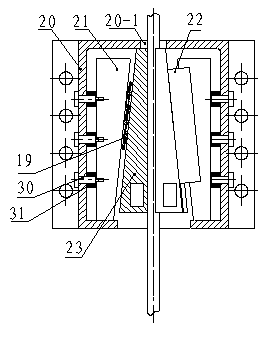

[0023] exist figure 1 , 2 Among them, the vertical shaft hoisting bucket anti-fall braking carriage includes a top beam 1-1, a bottom beam 1-3 set on the hoisting wire rope 4, and longitudinal beams fixed on both sides of the top beam 1-1 and the bottom beam 1-3. Frame body 1 composed of 1-2; the wire rope 4 between the top beam 1-1 and the bottom beam 1-3 is sequentially provided with a connecting block 5 and three rope clips 17 clamped by bolts and lifting wire rope 4, both sides The upper and lower sides of the longitudinal beam 1-2 are respectively provided with the guide sleeve 7 of the suit stabilization rope 27, and the upper part of the longitudinal beam 1-2 on both sides is equipped with anti-falling catch pliers 8 symmetrically by bolts, and the lower part of the longitudinal beam 1-2 on both sides The vertical slider guide groove 26 is symmetri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com