Self-adaptive carrying clamp for aluminum foil coil

An adaptive, aluminum foil roll technology, applied in transportation and packaging, cleaning methods and utensils, and pollution prevention methods, etc., can solve the problems of low handling efficiency and poor adaptability of aluminum foil rolls, and achieve improved sliding stability, high efficiency and stability clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

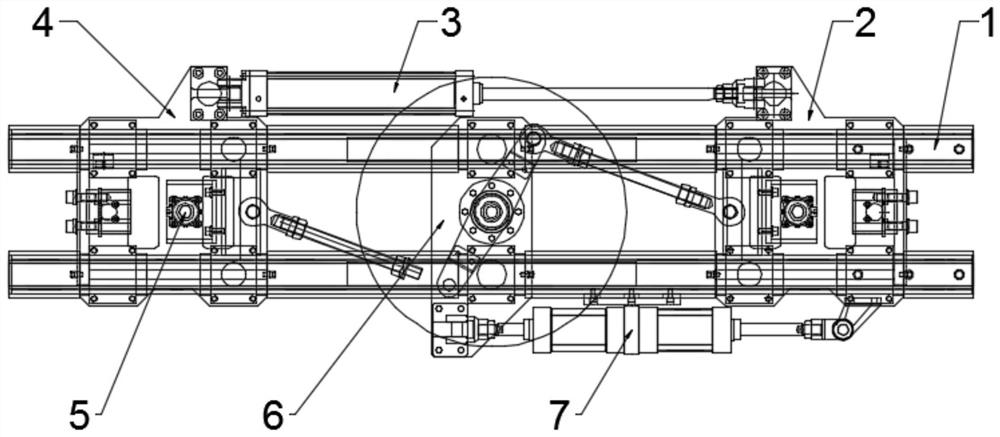

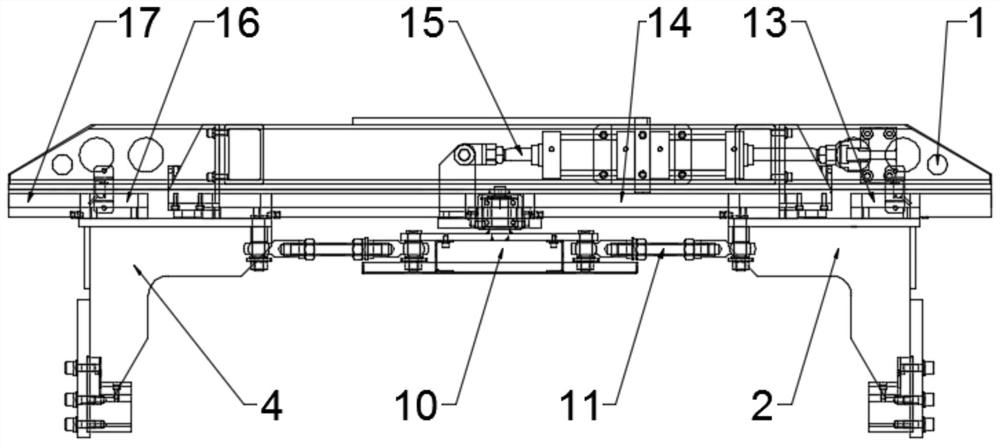

[0022] Such as figure 1 , 2 , The self-adaptive handling fixture for aluminum foil rolls shown in 3 includes a guide rail 1, and the guide rail 1 is a linear guide rail, preferably two, to ensure stable operation; the first splint 2 and the second splint that are slidingly connected to it are installed on the guide rail 1 4. The second splint 4 is connected to the first splint 2 through the clamping cylinder 3, and the clamping cylinder 3 is arranged on the side of the guide rail 1, that is, the expansion and contraction of the clamping cylinder 3 brings the first splint 2 and the second splint. The splints 4 are close to or far away from each other; the second splint 4 and the first splint 2 are equipped with a positioning pin 5 that matches the aluminum foil roll, that is, it is fixed by the positioning pin 5 and the roll material hole of the aluminum foil roll. , and then bring the first clamping plate 2 and the second clamping plate 4 close to each other through the clamp...

Embodiment 2

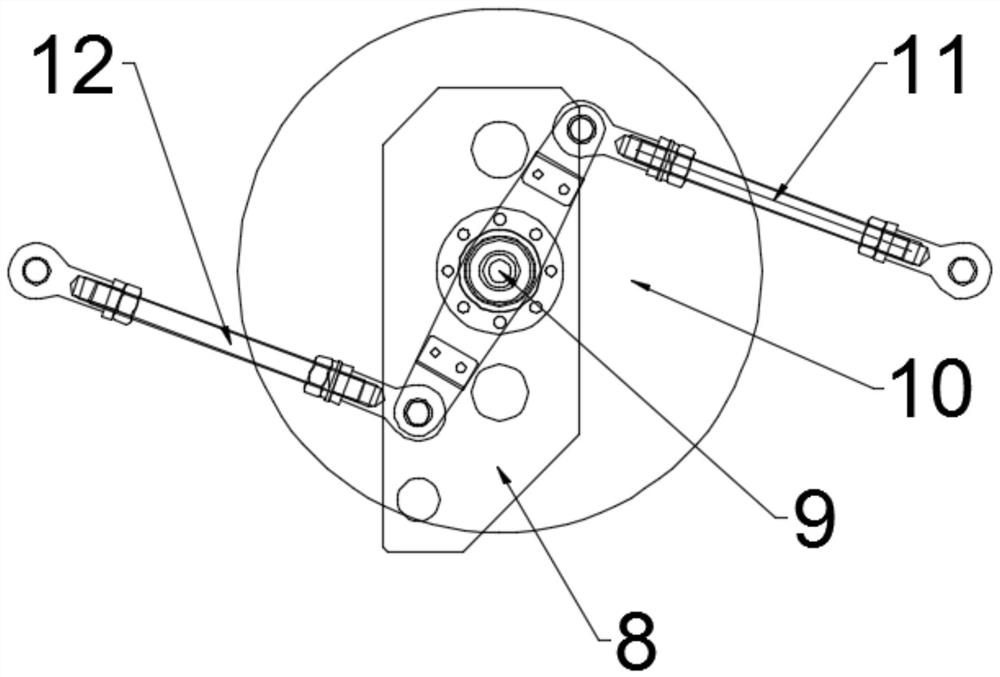

[0027] This embodiment is further optimized on the basis of embodiment 1, as Figure 4 As shown, a bearing 18 is installed inside the fixing plate 8 , and the bearing 18 is sheathed on the outside of the rotating shaft 9 , that is, the rotation stability of the fixing frame 10 is improved by arranging the bearing 18 .

[0028] Further, the first fixed shaft 19 and the third fixed shaft 21 are fixedly installed in the fixed frame 10, the third fixed shaft 21 and the first fixed shaft 19 are arranged symmetrically with respect to the rotating shaft 9, and the first connecting rod 11 One end is sleeved on the outside of the first fixed shaft 19 and connected to it in rotation, and the other end is installed with a second fixed shaft 20 connected to it in rotation. The second fixed shaft 20 is fixedly installed in the first splint 2, and the second connection One end of the rod 12 is sheathed on the outside of the third fixed shaft 21 and is rotatably connected with it, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com