Yarn conveying device on knitting machine

A yarn feeding device and knitting machine technology, applied in knitting, weft knitting, warp knitting, etc., can solve problems such as yarn fluffing, yarn clearer grooves, affecting the quality of knitting machine fabrics, etc., to achieve constant tension, The effect of improving quality and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

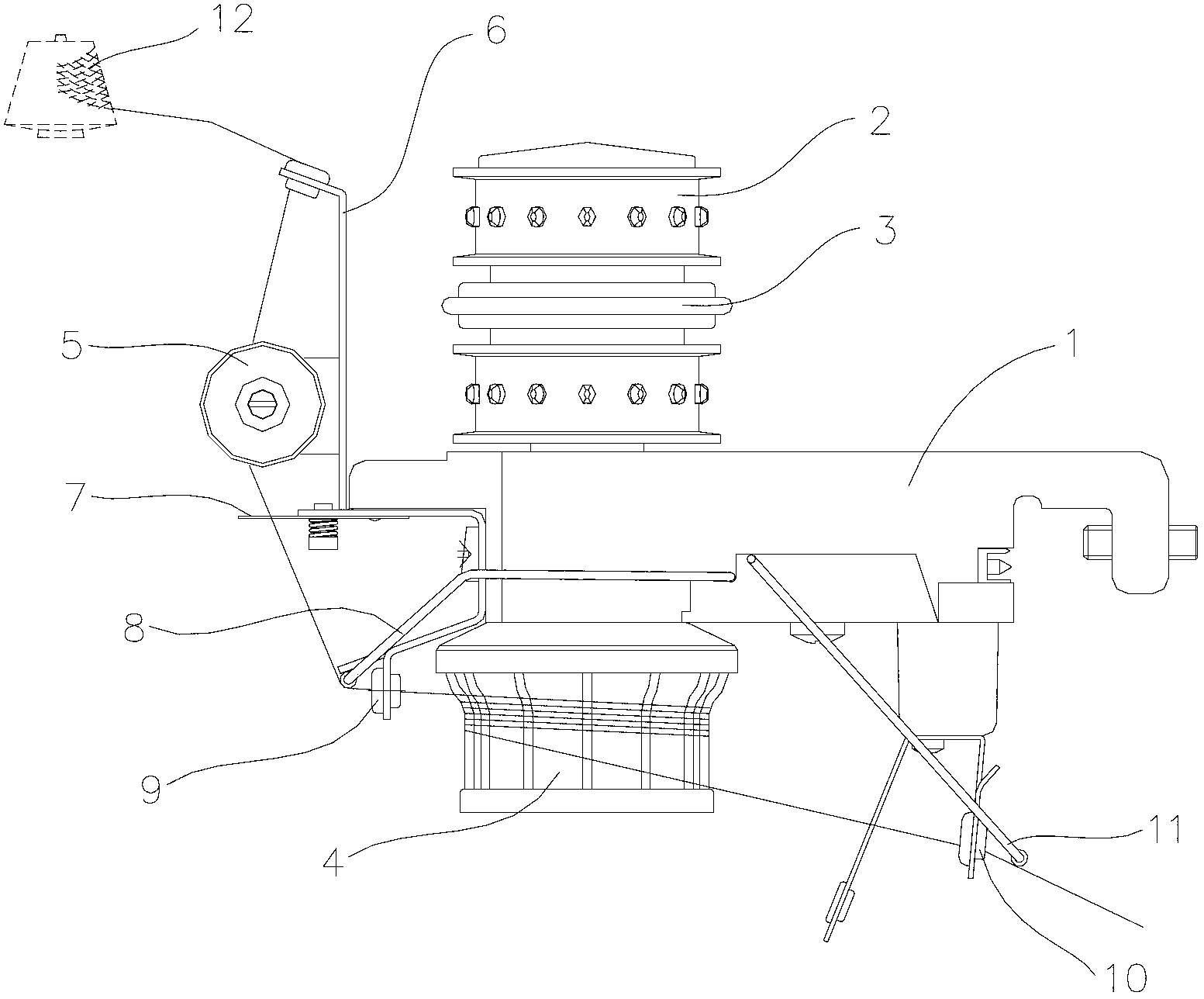

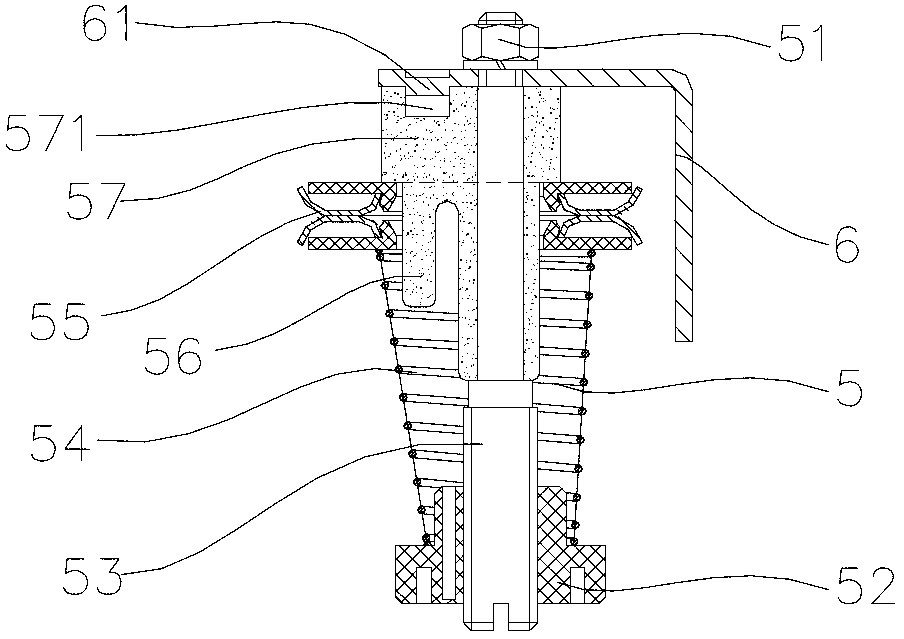

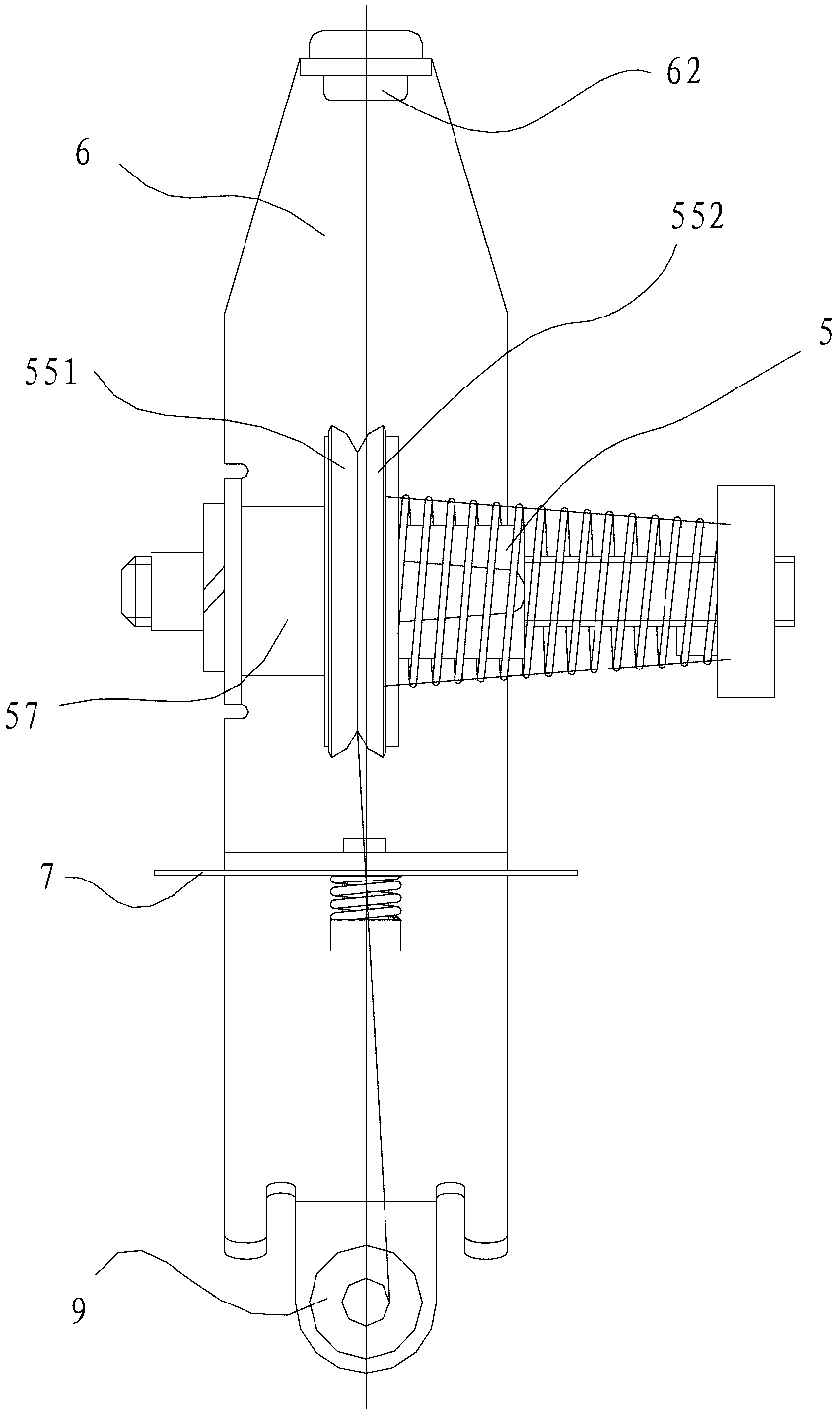

[0020] Such as figure 1 , figure 2 , image 3 and Figure 4 The yarn feeding device on the shown knitting machine includes a housing 1 and a transmission pulley 2, a clutch 3, a wire feeding wheel 4 and a main shaft thereon. The main shaft runs through the housing 1 up and down, the upper part of the main shaft is connected with the transmission pulley 2 and the clutch 3, and the lower part of the main shaft is connected with the transmission pulley 4. Lead frame 6, yarn clamping assembly 5, yarn clearer 7, front detection rod 8, yarn input ceramic ring 9, yarn output ceramic ring 10 and rear detection rod 11 are installed in the shell in sequence from yarn inlet to yarn outlet. On the body 1, the clamping assembly 5 is installed on the housing 1 through the lead frame 6.

[0021] The thread delivery wheel 4 is sequentially provided with a connected yarn introduction area 411, a yarn storage area 421 and a waste silk export area from top to bottom. The yarn introduction ...

Embodiment 2

[0028] Such as figure 1 , figure 2 , image 3 and Figure 5 The structure and data of the yarn feeding device on the knitting machine shown are the same as those in Embodiment 1, the only difference is that the waste silk export body 43 also includes a waste silk transition cylinder 43C, and the waste silk temporary storage cone 43A and the waste silk export cone 43B pass through The waste silk transition cylinder 43C is connected, and the diameter of the waste silk transition cylinder 43C is the same as the diameter of the top of the waste silk export cone 43B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com