Assembled waist rail

A prefabricated, waist-beam technology, applied in construction, excavation, infrastructure engineering, etc., can solve the problems of delaying construction period, affecting construction safety, easy deformation, etc., achieving good structural rigidity, convenient installation, and saving raw material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

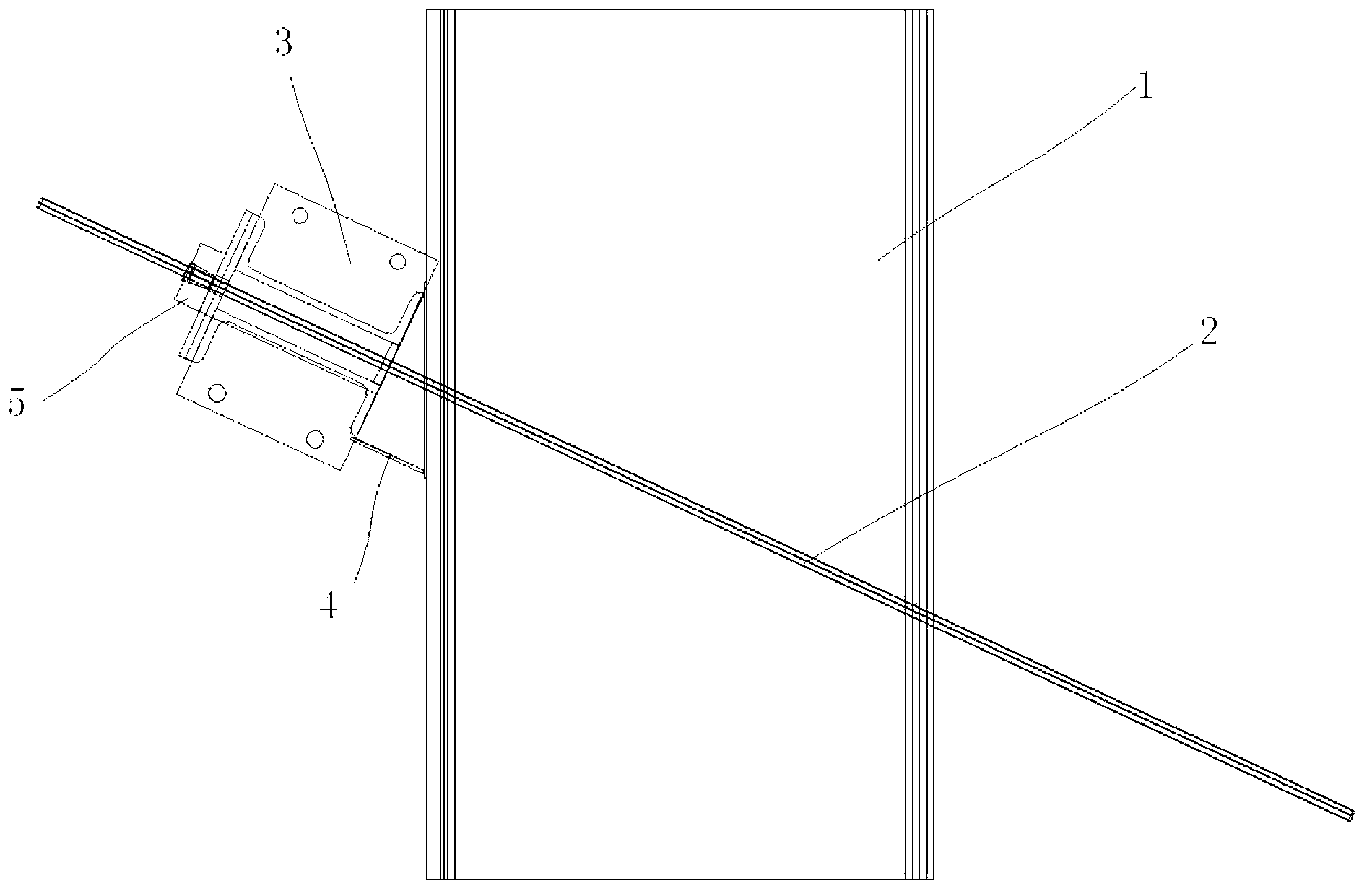

[0028] see figure 1 and figure 2 , in this embodiment, the vertical retaining structure is a SMW construction method pile, and the steel 1 is inserted. The profile steel 1 has an "I"-shaped cross section, the assembled waist beam 3 rests on the side of the profile steel 1 as a whole, and the anchor bar 2 passes through the middle of the two parallel profile steel 1, and is locked on the side of the profile steel 1 through the waist beam.

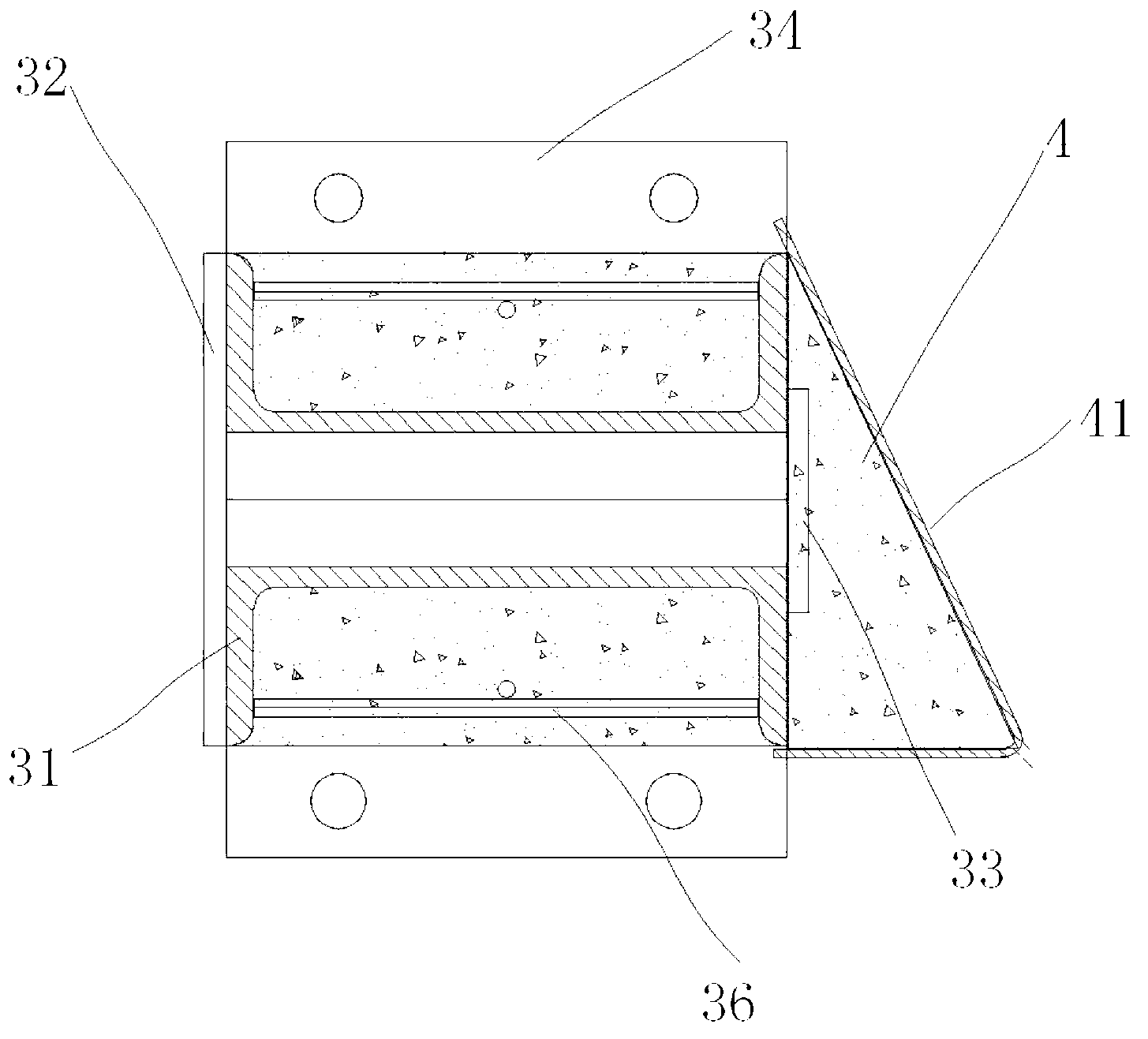

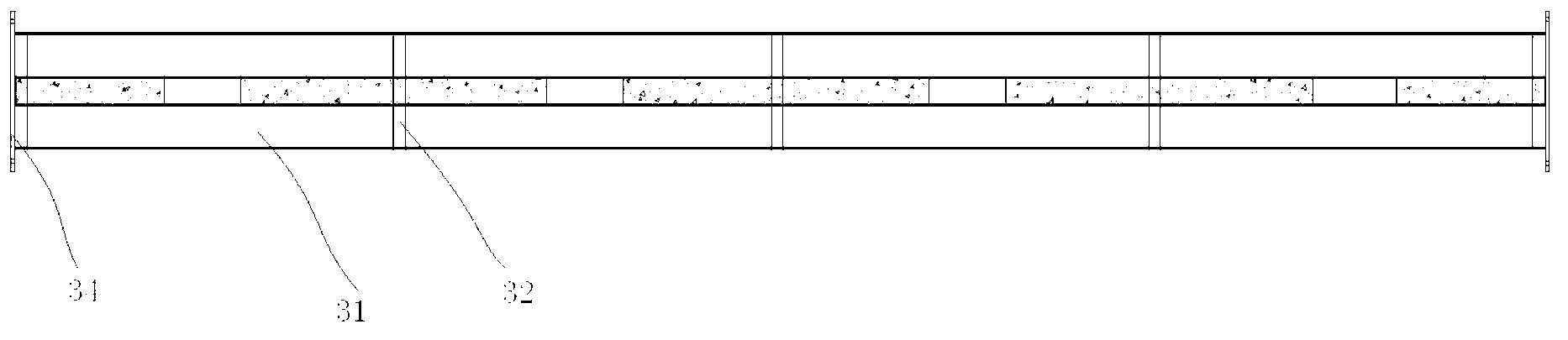

[0029] see figure 2 , Figure 2a , Figure 2b , image 3 , Figure 4 , assembled waist beam 3, including a pair of channel steel 31, channel steel 31 is set back to back, one side of channel steel 31 is welded together with steel plate 32, the upper and lower length of steel plate 32 extends to the edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com