Auxiliary forming device of automobile side guardrail supporting ribs

A support rib and car side technology, applied in the field of mechanical processing, can solve the problems of difficulty in one-time molding of arc radius, low efficiency, and high labor intensity, etc., to improve the strength of molding operations, safe and convenient operation, and low input cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

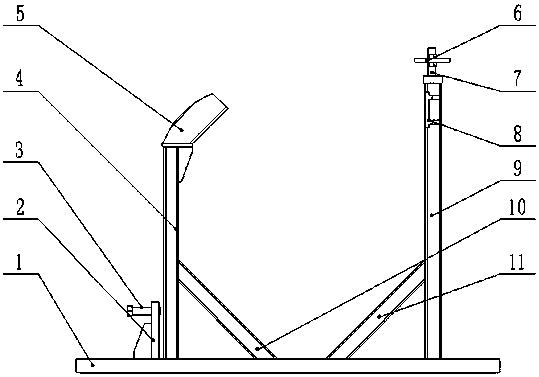

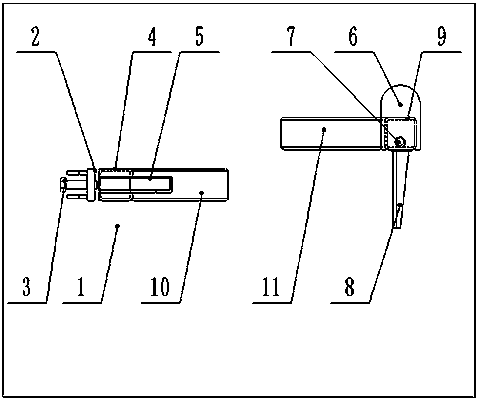

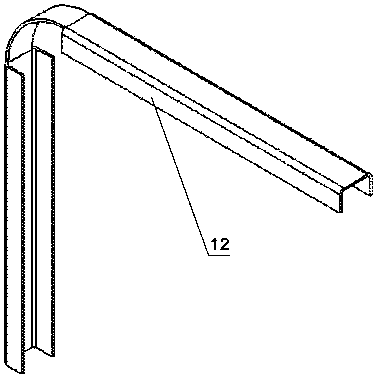

[0021] Now, the technical solutions in the embodiments of the present invention will be clearly and completely described in conjunction with the accompanying drawings. This figure is a simplified schematic diagram and only schematically illustrates the basic structure of the present invention.

[0022] according to figure 1 , figure 2 As shown, one end of the base 1 is vertically fixedly connected with a horizontal positioning seat 2 and a limiting column 4 in turn, and the other end is vertically fixedly connected with a positioning column 9; The threaded holes are equipped with pre-tightening bolts 3; the upper end of the limit column 4 is fixedly connected with a profiling arc seat 5; the positioning column 9 is fixedly connected with a horizontal limit seat 8, and the horizontal limit A longitudinal pre-tightening bolt 7 is arranged on the seat 8; a pressure plate 6 is sleeved on the longitudinal pre-tightening bolt 7 . The arc surface of the profiling arc seat 5 is ada...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com