Fault diagnosis system and method for automobile safety air bag assembly working procedure

A fault diagnosis system and assembly process technology, applied in electrical testing/monitoring, biological neural network models, etc., can solve problems such as low fault diagnosis accuracy, false alarms, and delays in time, so as to achieve practicality and improve accuracy , to avoid local optimal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

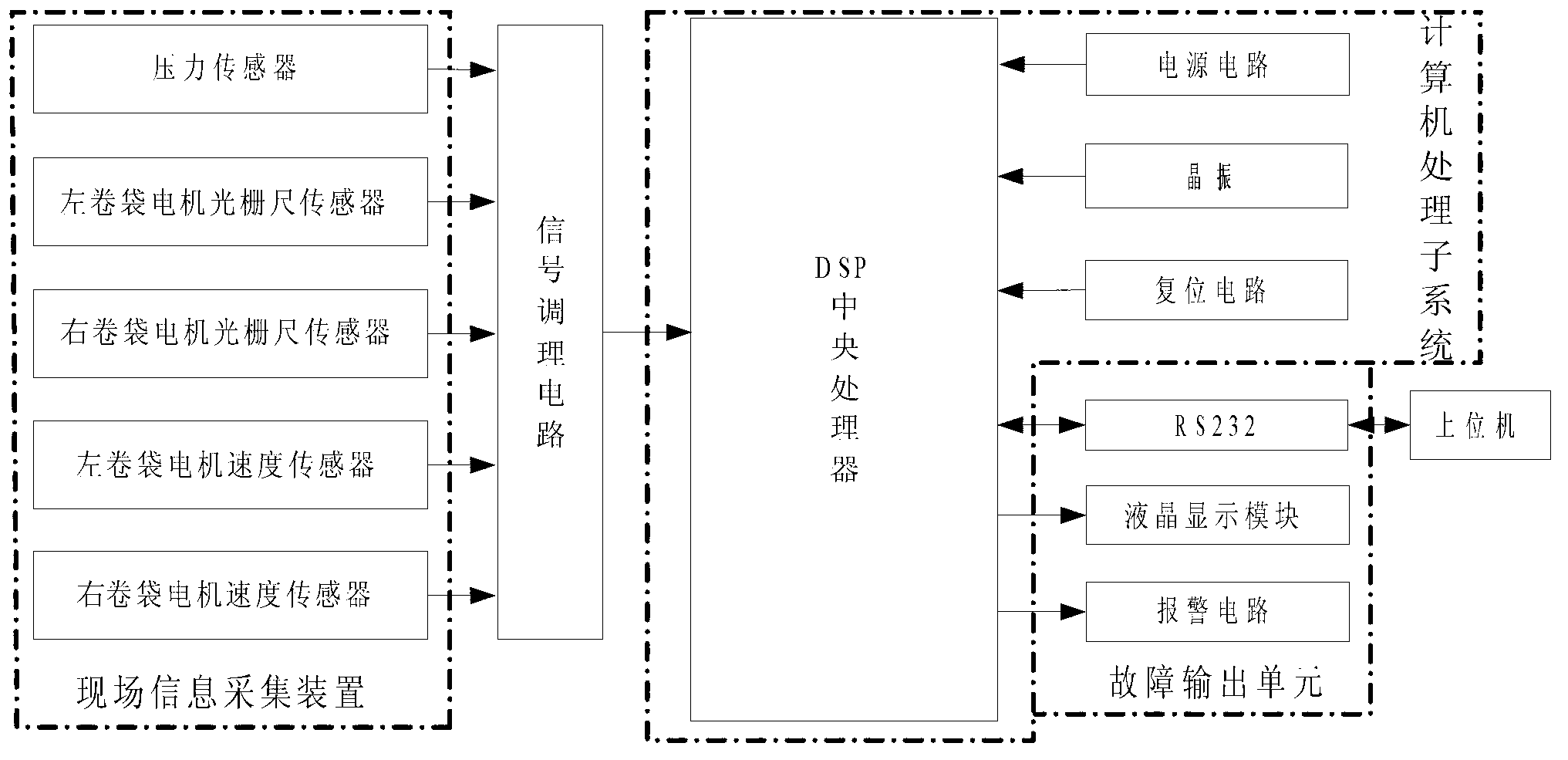

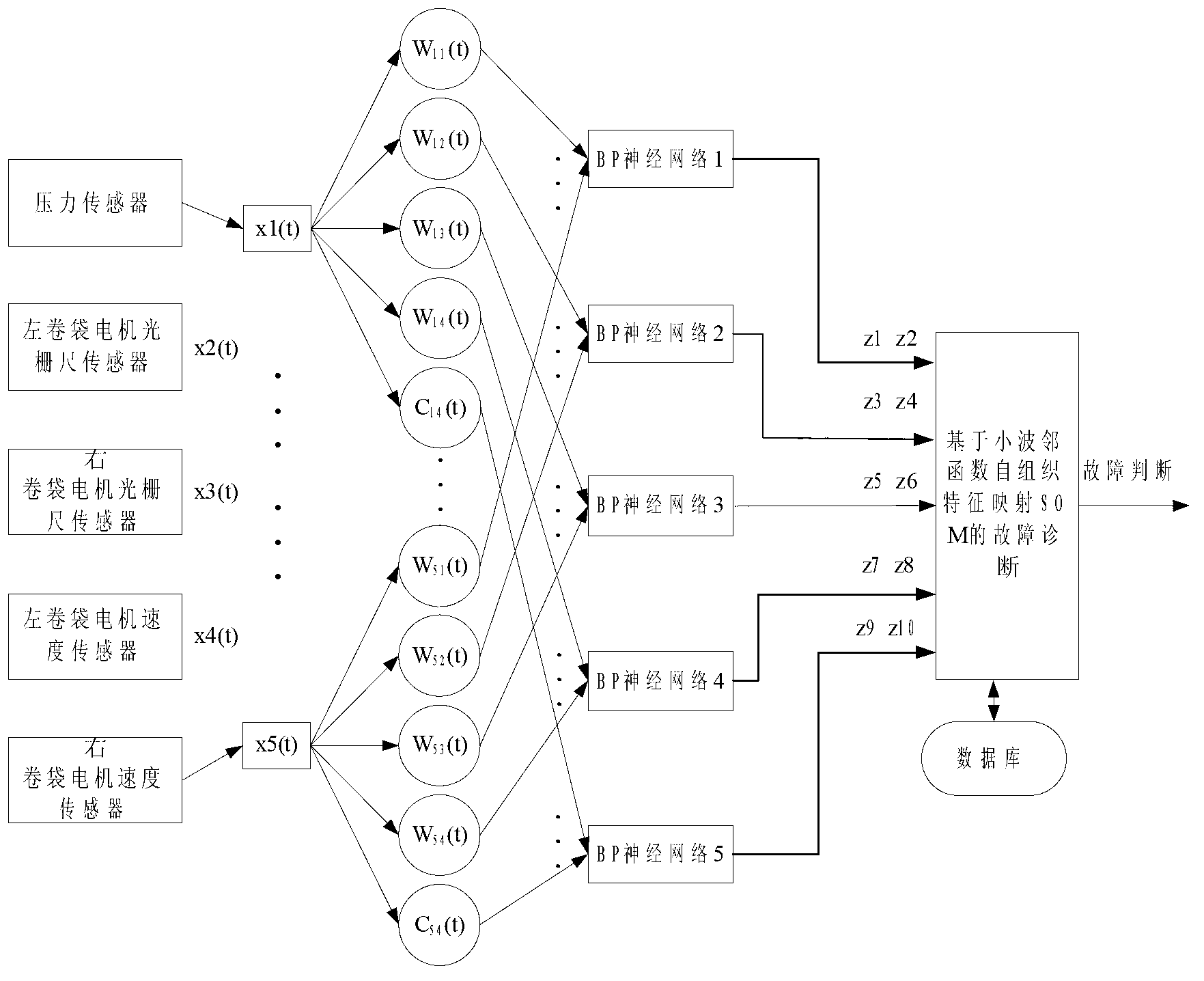

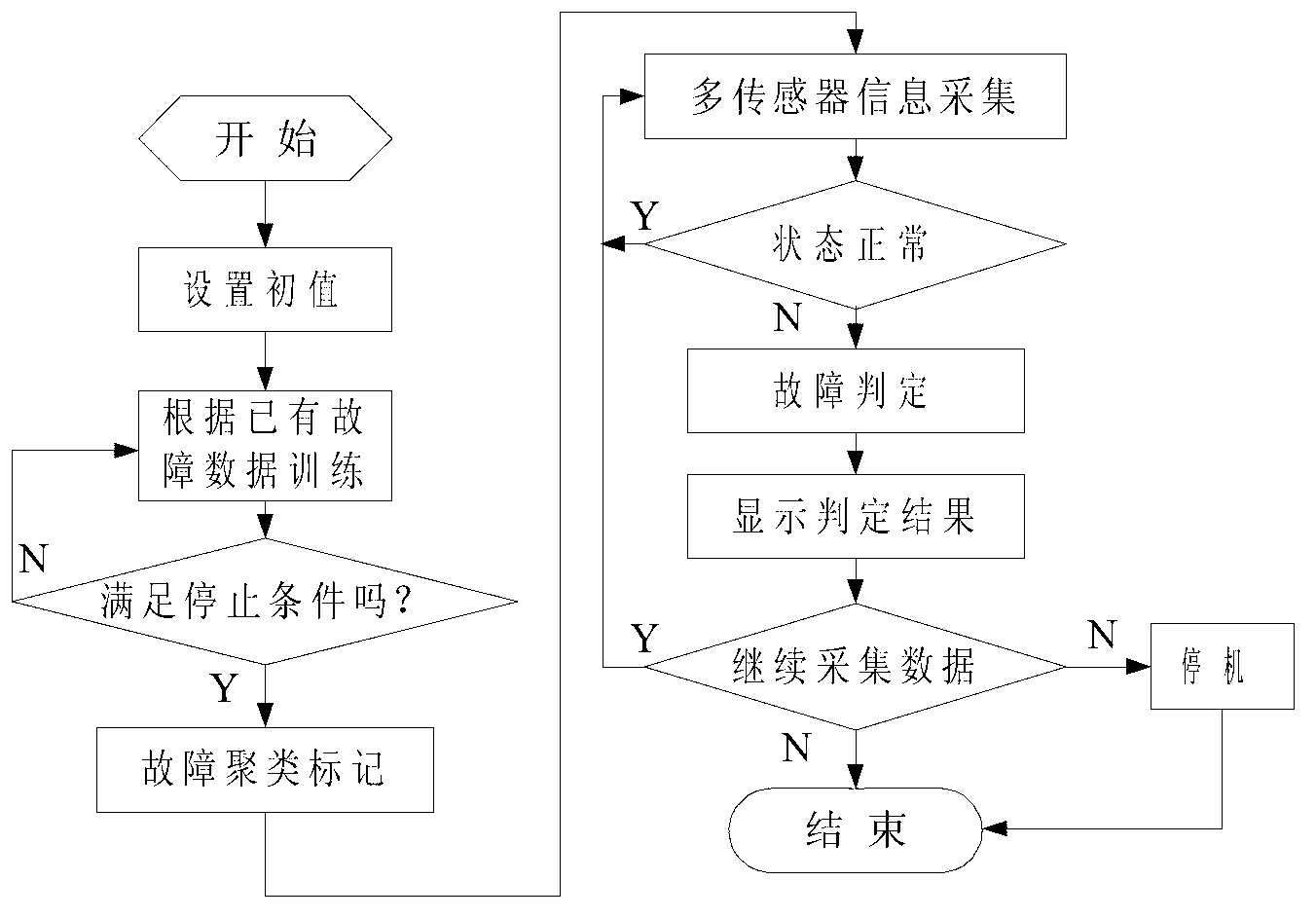

[0027] Such as figure 1 As shown, the fault diagnosis system of the automobile airbag assembly process of the present invention includes on-site information collection device, signal conditioning circuit, computer processing subsystem, fault output unit and upper computer; HBMC9B force sensor from Haofang Instrument Technology Co., Ltd.), the grating ruler sensor of the left bag motor and the grating ruler sensor of the right bag motor (using the QH-600 grating line displacement sensor of Changchun Qihai Photoelectric Technology Co., Ltd.), the left bag motor Speed sensor and right bag motor speed sensor (adopting the E1036 small matrix photoelectric encoder of Changchun Institute of Optics, Fine Mechanics and Physics, Chinese Academy of Sciences); Power supply circuit, crystal oscillator and reset circuit; the fault output unit includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com