Thermal overload relay with current transformers

A thermal overload relay, current transformer technology, applied in circuits, electrical components, parts of protection switches, etc., to prevent electric shock hazards and avoid the effect of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

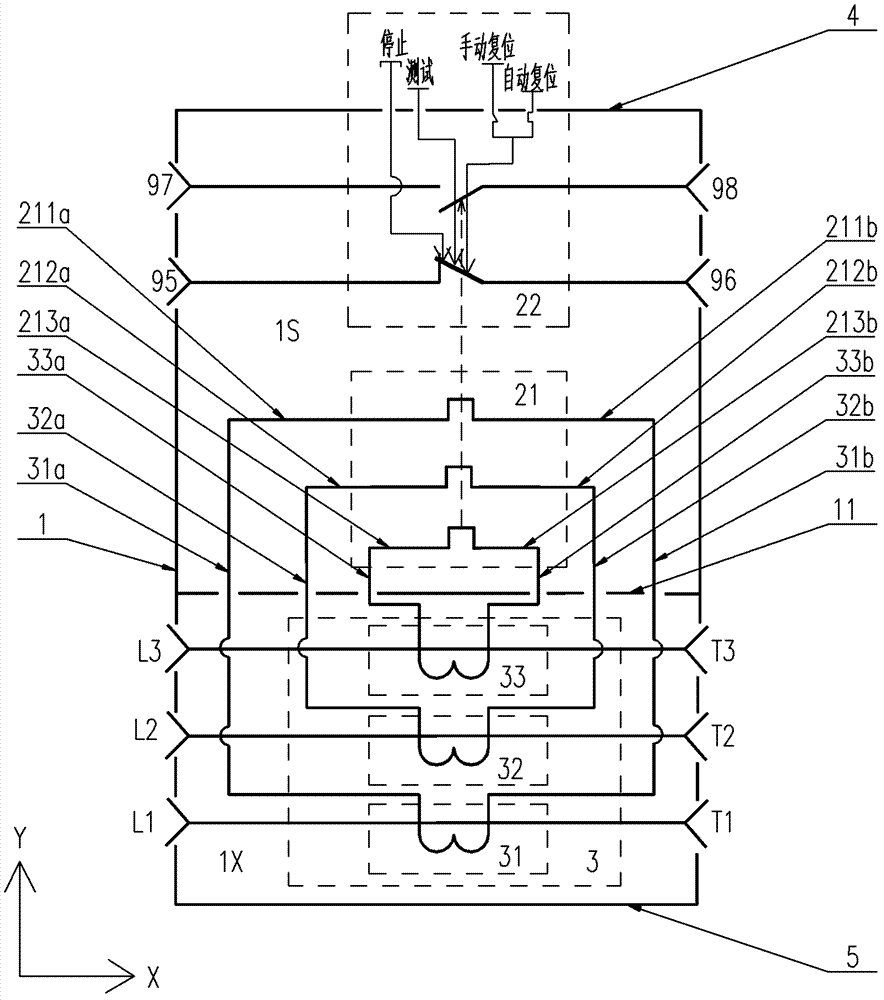

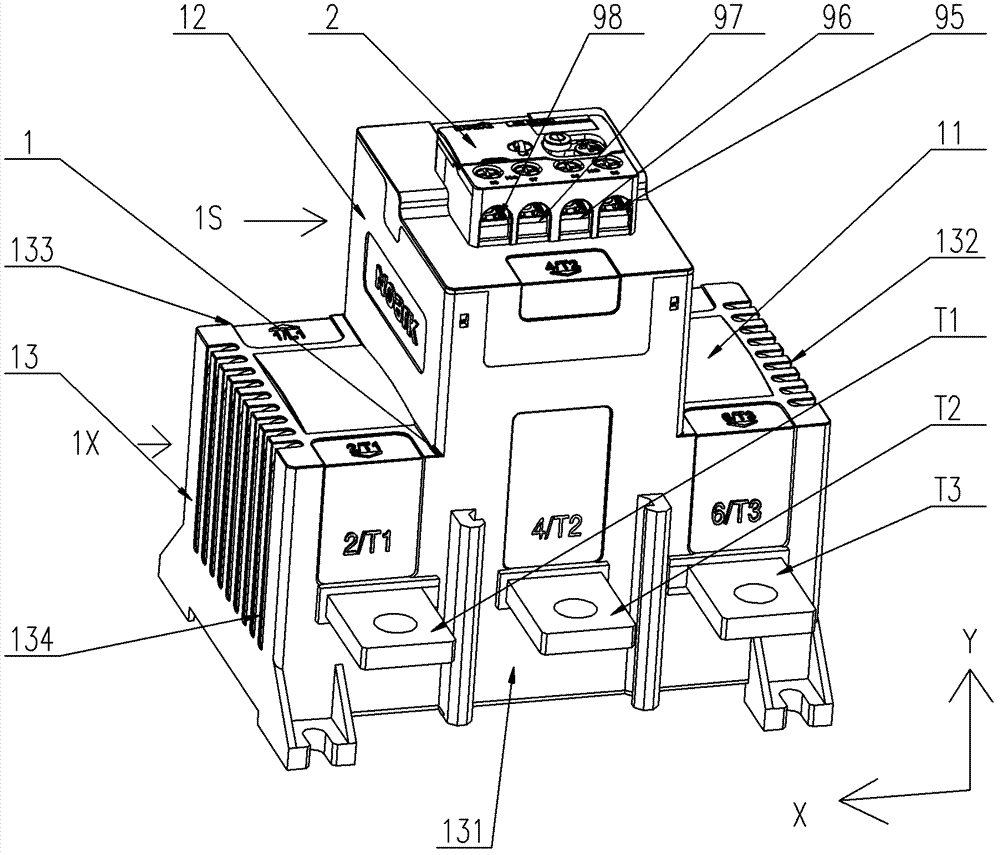

[0029] The following is attached Figure 1-11 Several specific implementations of the thermal overload relay with current transformer of the present invention are described in detail, wherein Figure 1-8 Can be generally used in the first embodiment or the second embodiment of the thermal overload relay with current transformer of the present invention, and Figure 9-11 It is only applicable to the first embodiment of the thermal overload relay with current transformer of the present invention. The current transformer of the first embodiment is arranged in a zigzag shape, and the current transformer of the second embodiment is arranged in a zigzag shape (not shown in the drawings). out). The thermal overload relay with current transformer of the present invention is not limited to the description of the following embodiments.

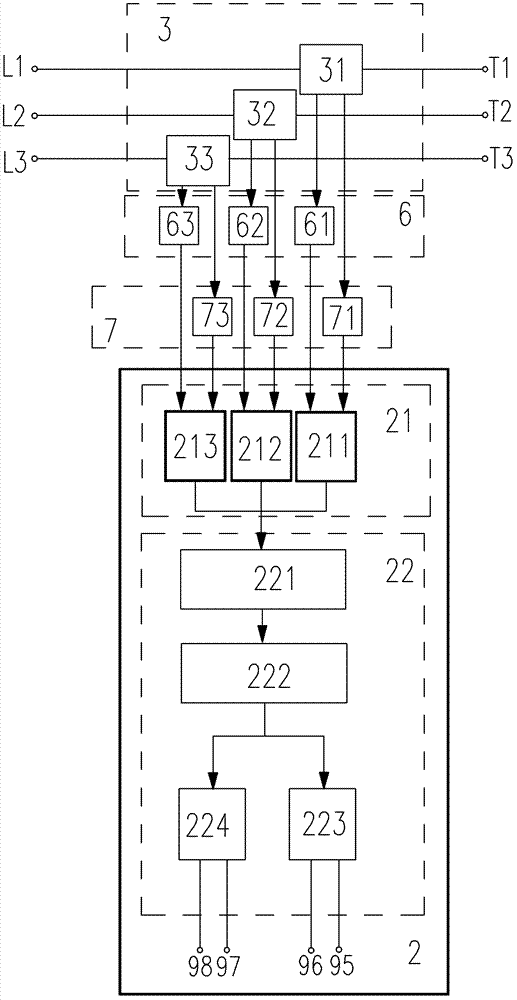

[0030] figure 1 It is a functional block diagram of the thermal overload relay with current transformer of the present invention, in which the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com