Drying oven structure for separating soil animals by using Tullgren method

A technology of soil animals and ovens, which is applied in the direction of separating microorganisms, protozoa, and dryers for static materials, etc. It can solve the problems of not strict temperature control, insufficient collection accuracy, and inability to automate, so as to achieve simple and convenient installation and reduce human interference. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

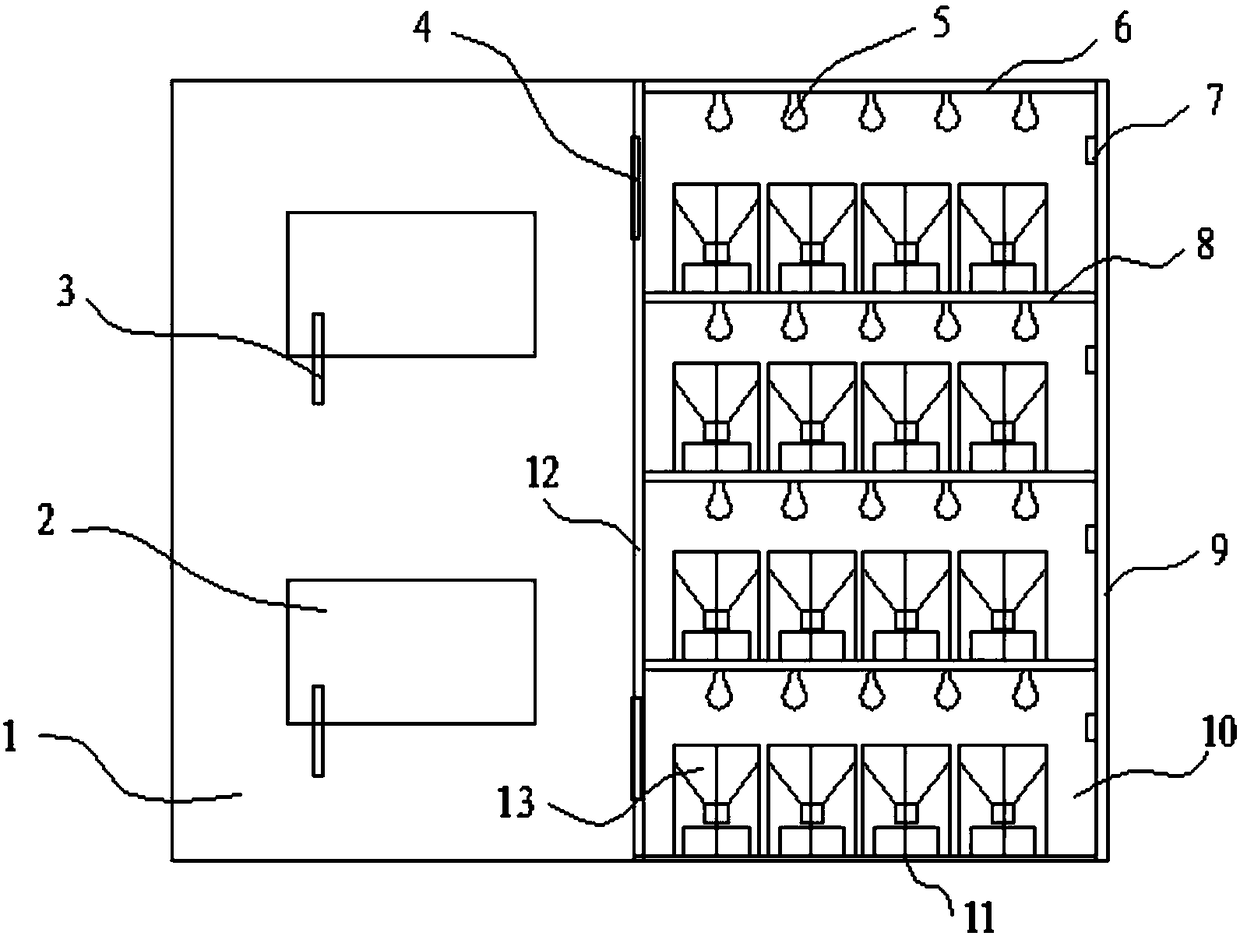

[0018] Embodiment 1: as attached figure 1 Shown, a kind of oven structure that adopts Tullgren method to separate soil animal, it comprises several experiment funnels 13, and it also comprises base plate 11 and top plate 6, is fixedly connected with left side plate 12, right side plate between described bottom plate 11 and top plate 6. Side plate 9 and rear end plate 10, door 1 is hinged by hinge 4 on the side of left side plate 12, between left side plate 12 and right side plate 9, be fixedly connected with horizontal three-layer laminate 8, in A number of light bulbs 5 are arranged below the laminate 8 and the top plate 6, and the bulbs 5 on each floor are connected in series and have a temperature control switch 7 in series, and an experimental funnel 13 is placed on the laminate 8 and the bottom plate 11.

[0019] Further, a glass window 2 is inlaid on the door 1 , and a thermometer 3 is arranged beside the glass window 2 . The situation in the box can be observed through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com