A forward-moving safety buffer forklift with easy replacement of fuel tank

An easy-to-replace, fuel tank technology, applied in the direction of lifting equipment safety devices, hoisting devices, etc., can solve the problems of poor pin maintenance performance, pin wear, bulky and other problems, achieve convenient modification and maintenance, prevent electric shock hazards, Easy and quick installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

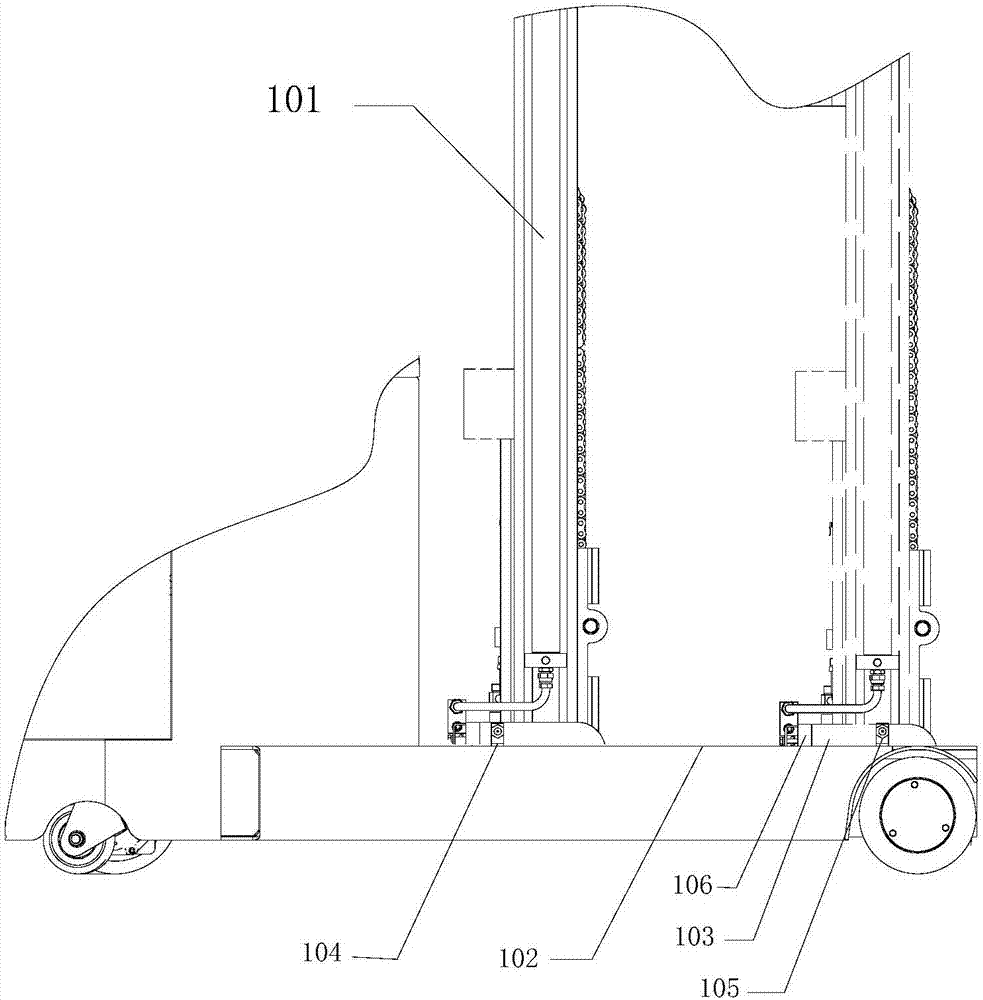

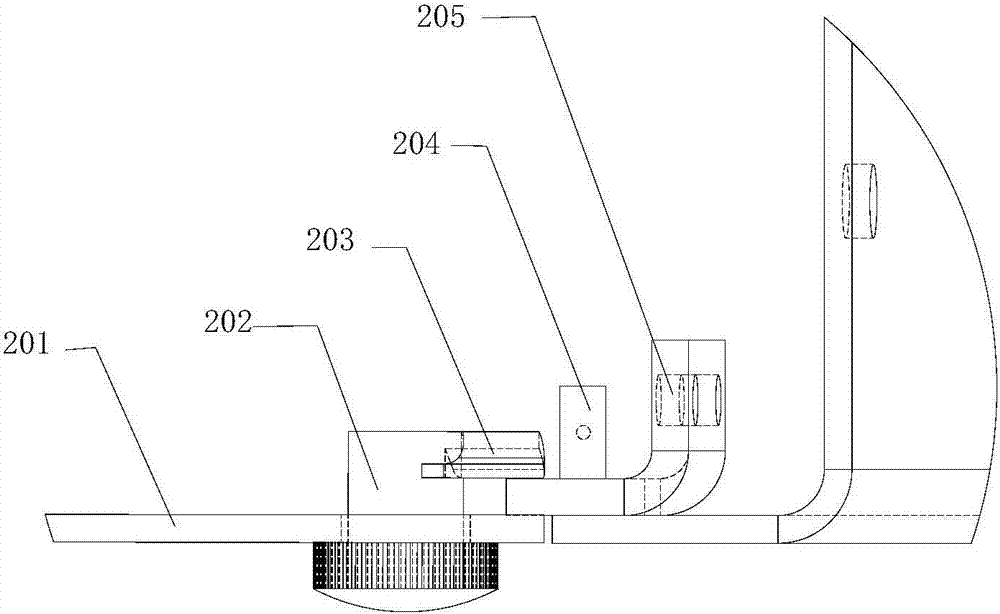

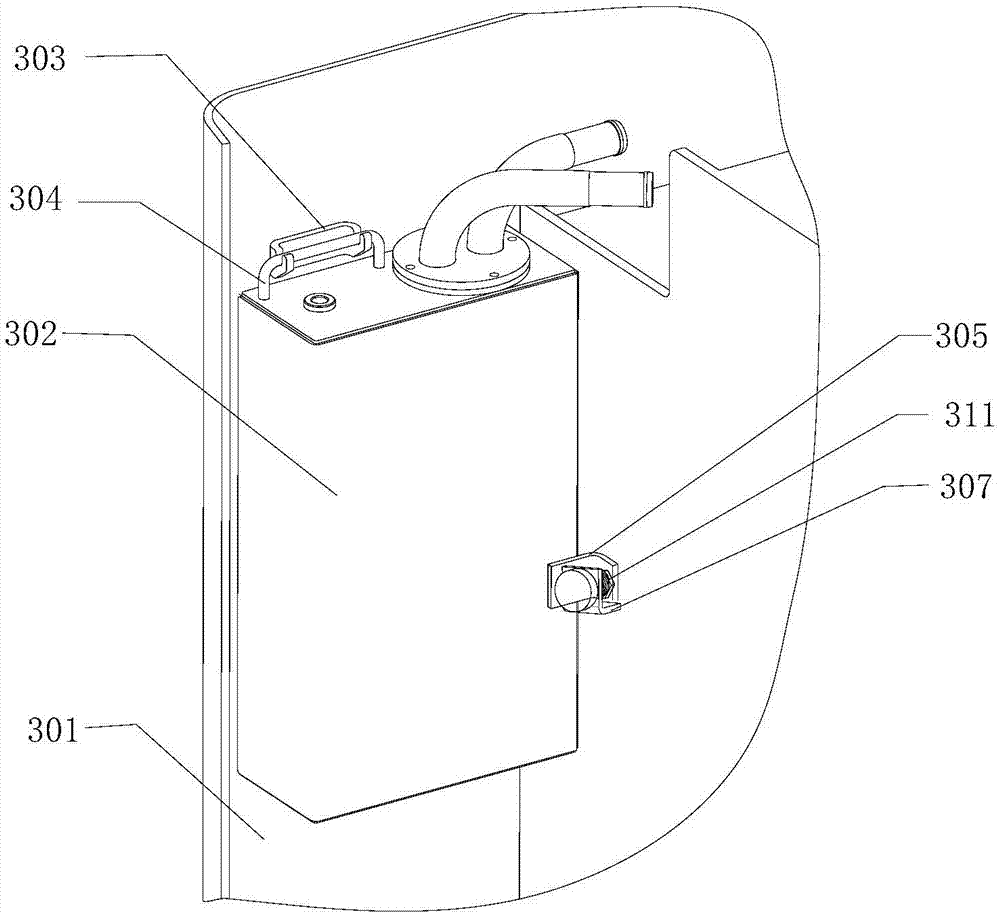

[0020] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8, a forward-moving safety buffer forklift that is easy to replace the fuel tank of the present invention, comprising a fuel tank fixing structure 3, a door lock safety device 2, a forward-moving buffer device 1, and a connecting pin structure 4, and the forward-moving buffer device 1 includes a mast 101, gantry guide rail 102, forward pump 103, first distance sensing switch 104, second distance sensing switch 105, pump speed controller 106, the gantry 101 is installed on the gantry guide rail 102, and the forward moving pump 103 is installed on the door frame 101, the pump speed controller 106 is installed on the forward pump 103, the first distance sensing switch 104 and the second distance sensing switch 105 are installed on the door frame guide rail 102, the pump speed The controller 106 is connected to the forward pump 103, the first distance sensing switch 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com