Gantry type movable hoisting equipment with early warning and pedestrian collision prevention functions and applied to AGV (Automatic Guided Vehicle)

A kind of hoisting equipment and gantry-type technology, which is applied in the direction of mechanical equipment, hoisting equipment braking devices, hoisting devices, etc., can solve problems that affect the forward use of equipment, hidden safety hazards, low efficiency, etc., and improve hoisting efficiency and performance , Prevent pedestrian impact, move quickly and conveniently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

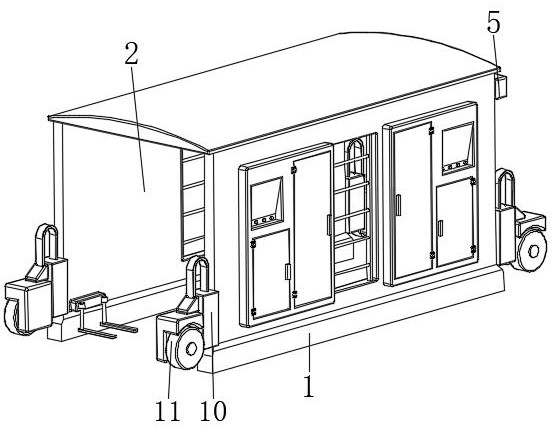

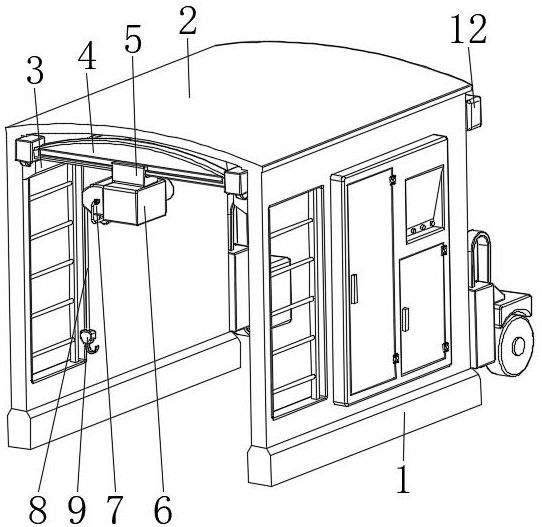

[0028] see Figure 1-Figure 6 , The present invention provides a technical solution: a gantry-type mobile hoisting equipment with early warning and pedestrian impact prevention applied to AGV, including a base 1, the top of the base 1 is fixedly connected with a gantry frame 2, and the inner wall of the gantry frame 2 corresponds to Both sides and near the top are fixedly connected with support rails 3, the top of the support rails 3 is provided with a beam 4, the bottom of the beam 4 is provided with a mobile crane 5, and the bottom of the mobile crane 5 is provided with an electric hoist 6, the surface side of the electric hoist 6 is provided with a processing device 7, the electric hoist 6 is wound with a wire rope 8, the wire rope 8 passes through the center of the processing device 7, the bottom end of the wire rope 8 is provided with a hook 9, and the gantry The bottom of the surface of the frame 2 and the position close to the base 1 is provided with a lifting mechanism...

Embodiment 2

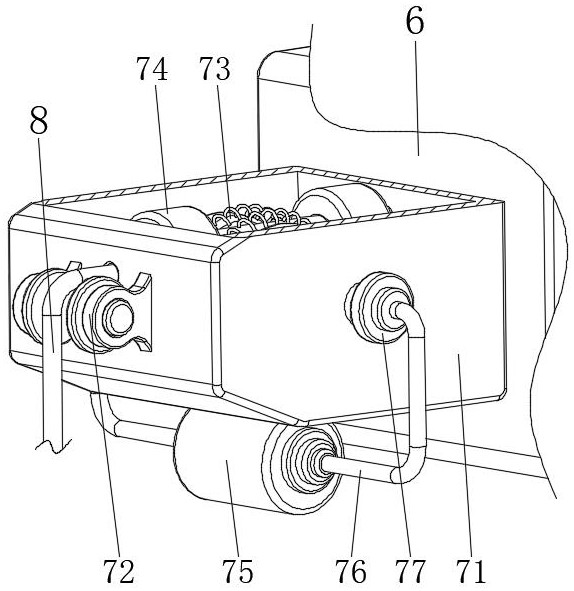

[0030] The processing device 7 includes a box body 71 , a surface side of the box body 71 is fixedly connected with the surface side of the electric hoist 6 , a guide wheel 72 is arranged on one end of the surface of the box body 71 , and a lubricating device 73 is arranged at the inner center of the box body 71 The inside of the box body 71 and on both sides close to the lubricating device 73 are provided with smear devices 74, the bottom center of the box body 71 is fixedly connected with a high pressure pump 75, and the oil inlet end of the high pressure pump 75 penetrates the bottom of the box body 71 and extends Inside, the oil outlet end of the high-pressure pump 75 is communicated with a connecting pipe 76. The top end of the connecting pipe 76 is provided with a rotating connector 77. One end of the rotating connector 77 is disposed at the end of the lubricating device 73. Under the guiding action of It is driven to rotate, and at the same time, the high-pressure pump ...

Embodiment 3

[0036] The applicator 74 includes a lower applicator 741, the lower applicator 741 is fixedly connected to the bottom of the inner wall of the box body 71 through a bracket, a tension spring 742 is fixedly connected to the top of the lower applicator 741, and an upper applicator 743 is fixedly connected to the top of the tension spring 742. , the inner wall of the lower applicator 741 and the inner wall of the upper applicator 743 are fixedly connected with a flexible applicator strip 744 .

[0037] The lower applicator 741 and the upper applicator 743 are both set in an arc shape, and the flexible applicator strips 744 are evenly distributed on the inner walls of the lower applicator 741 and the upper applicator 743. With the movement of the wire rope 8, the flexible applicator strip 744 wipes the lubricating oil on the surface of the wire rope 8 evenly, and under the elastic tension of the tension spring 742, the flexible applicator strip 744 is pressed, thereby helping the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com