Multifunctional pin taking-out device special for replacement of spring pin of insulator during live-line work

A live operation, multi-functional technology, applied in the direction of overhead line/cable equipment, etc., can solve the problems affecting power supply, human and material resource consumption, reducing use time, etc., to improve social and economic benefits, solve major problems, and prolong use. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

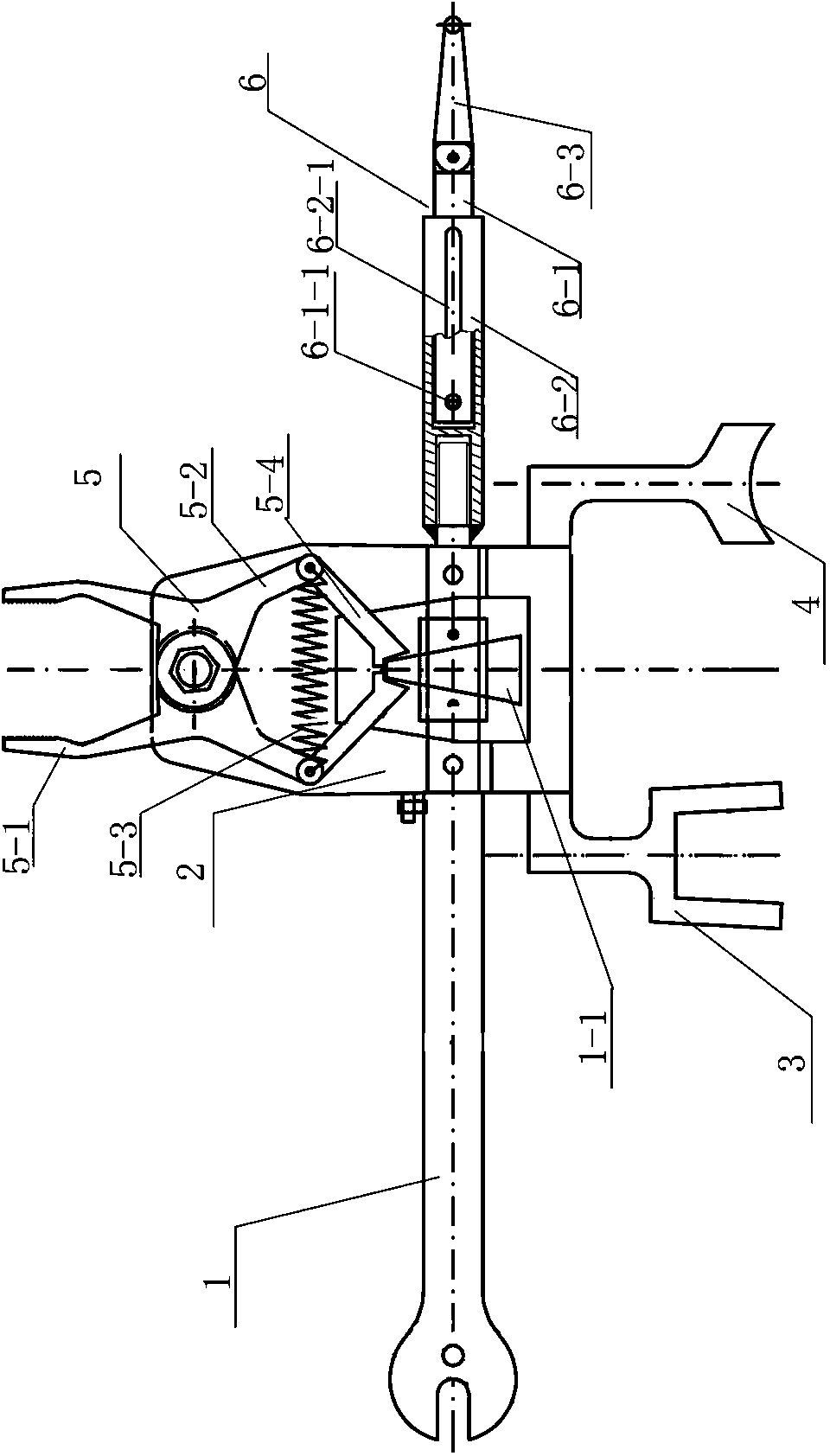

[0010] As described in the accompanying drawings, the embodiment of the present invention is a special multi-functional pin remover for live work to replace the insulator spring pin, which includes a main rod body 1 that can be connected to the insulating operating rod, impact hook 6, bracket 2, and single elbow Take and place fork 3, strike pin hammer 4, spring pin take and place pliers 5. The bracket 2 is fitted on the front part of the main rod body 1 behind the impact hook 6 . A knockout hammer 4 and a single elbow pick-and-place fork 5 are respectively fixed at the bottom of the support 2 , and spring pin pick-and-place pliers 5 are equipped on the support 2 top. The impact hook is composed of a hook rod 6-1, a hook rod installation sleeve 6-2 and a hook head 6-3. The hook rod installation sleeve 6-2 is detachably connected to the main rod 1. The hook rod 6 -1 is inserted in the hook rod installation sleeve 6-2, and two strip sliding holes 6-2-1 are symmetrically opened ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com