Bulk feeder parts holding case

A storage container and feeder technology, applied to electrical components, electrical components, conveyor objects, etc., can solve the problems of parts spilling outside, taking a long time, and poor storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

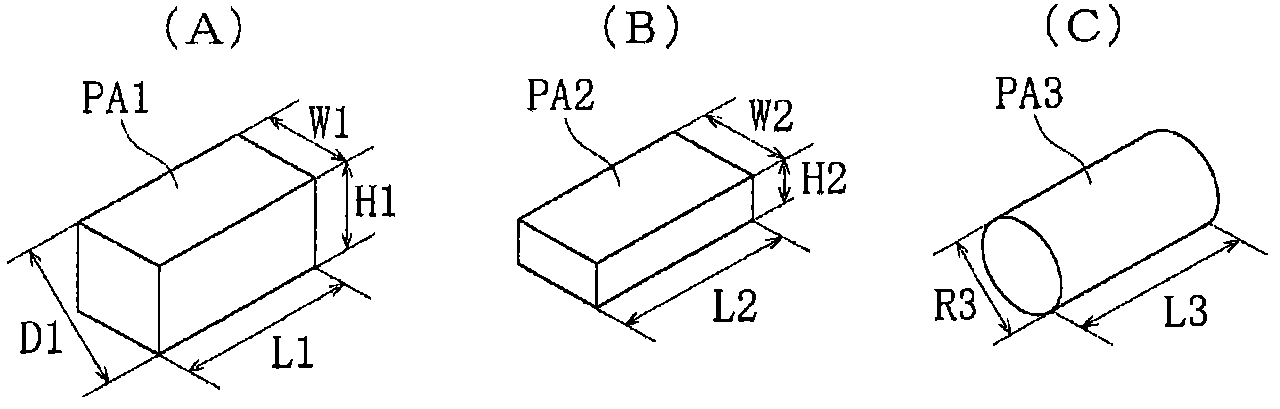

[0061] First, quote figure 1 , the "components that can be accommodated in the component storage container", that is, the components that can be used as supply objects will be described.

[0062] figure 1 The part PA1 shown in (A) is a rectangular parallelepiped having the dimensional relationship of length L1>width W1=height H1, figure 1 The part PA2 shown in (B) is a rectangular parallelepiped having the dimensional relationship of length L2>width W2>height H2, figure 1 Part PA3 shown in (C) has a cylindrical shape having a dimensional relationship of length L3>diameter R3.

[0063] Representative examples of these components PA1 to PA3 are electronic components such as small chip capacitors (chip condensers) and chip registers whose lengths L1 to L3 are 1.6 mm, 1.0 mm, 0.6 mm, or 0.4 mm. These electronic parts generally have external electrodes containing ferromagnetic materials, and depending on the type, also have internal conductors containing ferromagnetic materials,...

no. 2 approach

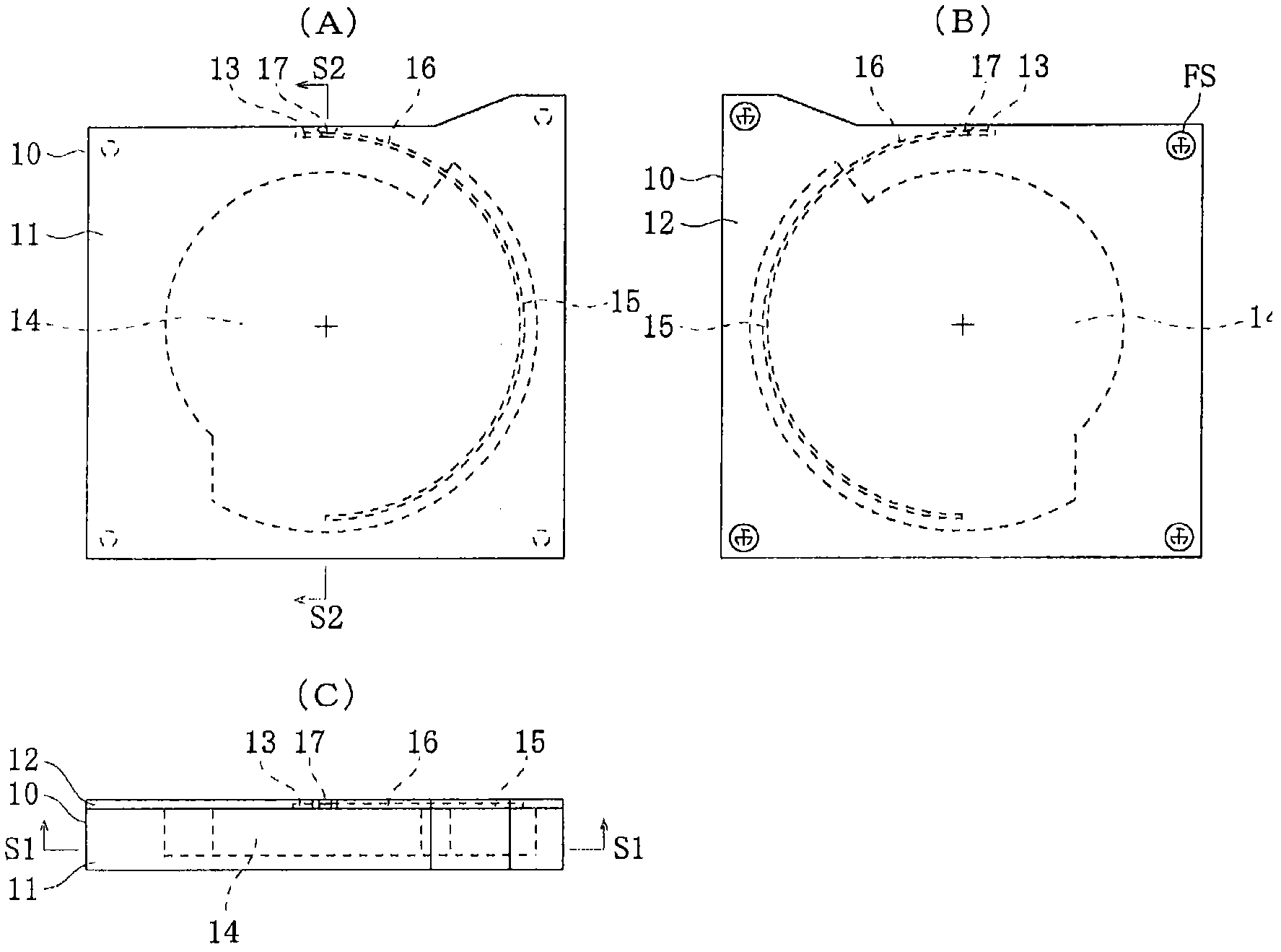

[0176] (Structure of Parts Storage Container (Second Embodiment))

[0177] Next, quote Figure 21 "The structure of the parts storage container (2nd embodiment)" is demonstrated. In this description, for ease of explanation, the Figure 21 The left, right, down, up, near front, and inside are called front, back, left, right, up, and down, respectively.

[0178] Figure 21 The illustrated parts storage container 10-1 differs from the above-described parts storage container 10 in that:

[0179] - A magnetizable stopper 13 - 1 is used as the stopper 13 .

[0180] The stopper 13-1 can be magnetized by the magnetic force of the permanent magnet 22c of the rotor 22, specifically, a rod made of a ferromagnetic material such as iron or nickel, or a bar made of a ferromagnetic material. A rod material in which a layer composed of another material belonging to a ferromagnetic body is formed by electroplating or the like on the entire surface of the base material, or a bar material ...

no. 3 approach

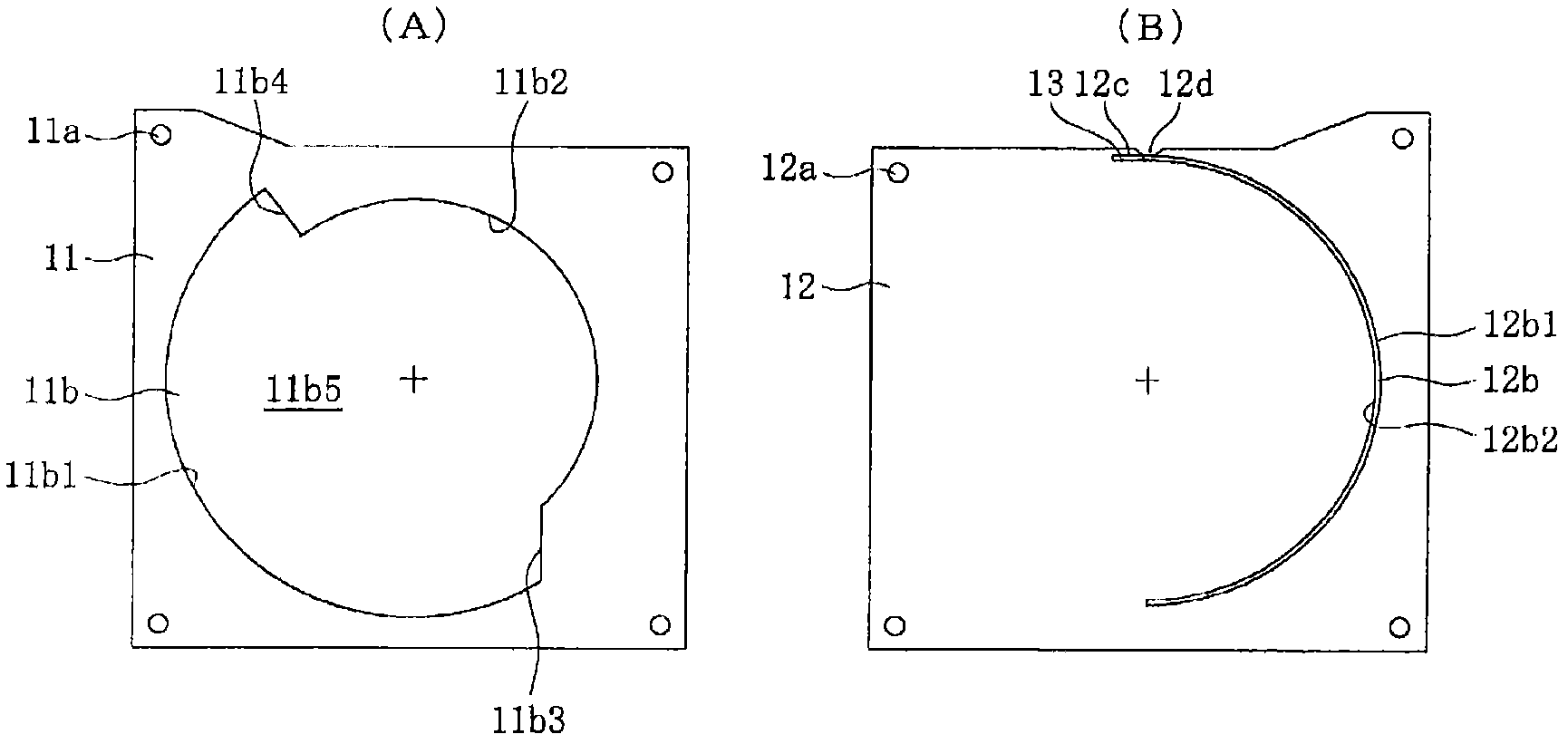

[0194] (Structure of Parts Storage Container (Third Embodiment))

[0195] Next, quote Figure 22 and Figure 23 , and "the structure of the parts storage container (third embodiment)" will be described. In the description, for the sake of illustration, the Figure 22 The left, right, lower, upper, near front, and inside are respectively called front, back, left, right, upper, and lower, and the same name Figure 23 directions comparable to these directions.

[0196] Figure 22 and Figure 23 The illustrated parts storage container 10-2 differs from the above-described parts storage container 10 in that:

[0197] - An elastically deformable shutter 18 that opens and closes the take-out port 17 when the rotor 22-1 operates is added.

[0198] The shutter 18 integrally has: a fixed part 18a; an elastic part 18b continuous with the fixed part 18a; an arm part 18c continuous with the elastic part 18b; The closing part 18d; the pushed part 18e provided at the front end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com