Disintegrating device

A technology of crushing device and screening device, applied in grain processing and other directions, can solve the problems of inability to guarantee, easy to reach the drum, etc., and achieve the effect of increasing the scope and opportunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

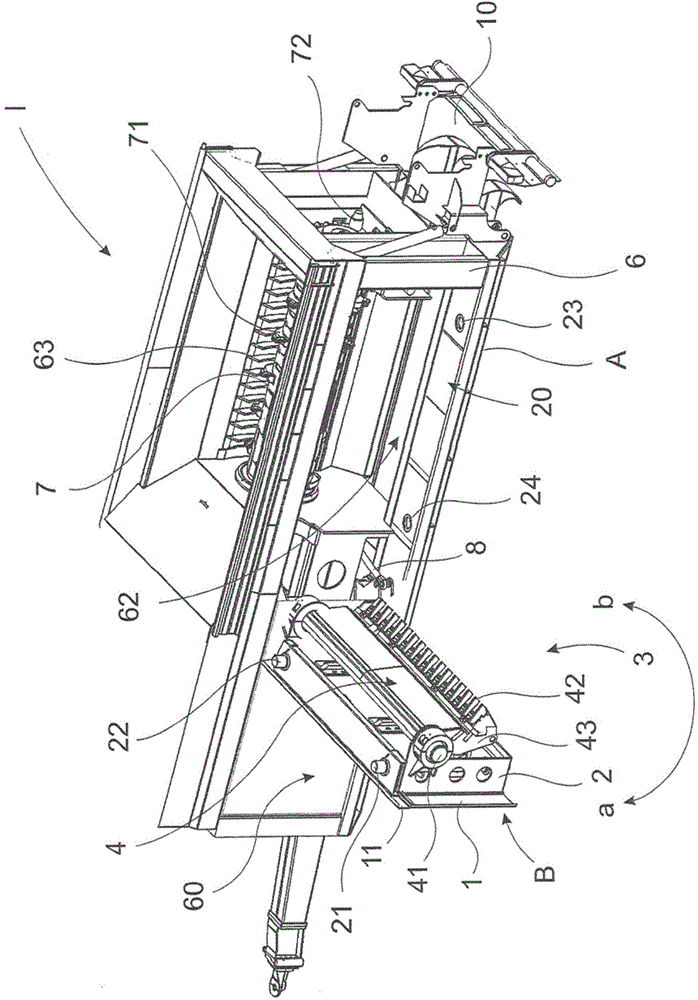

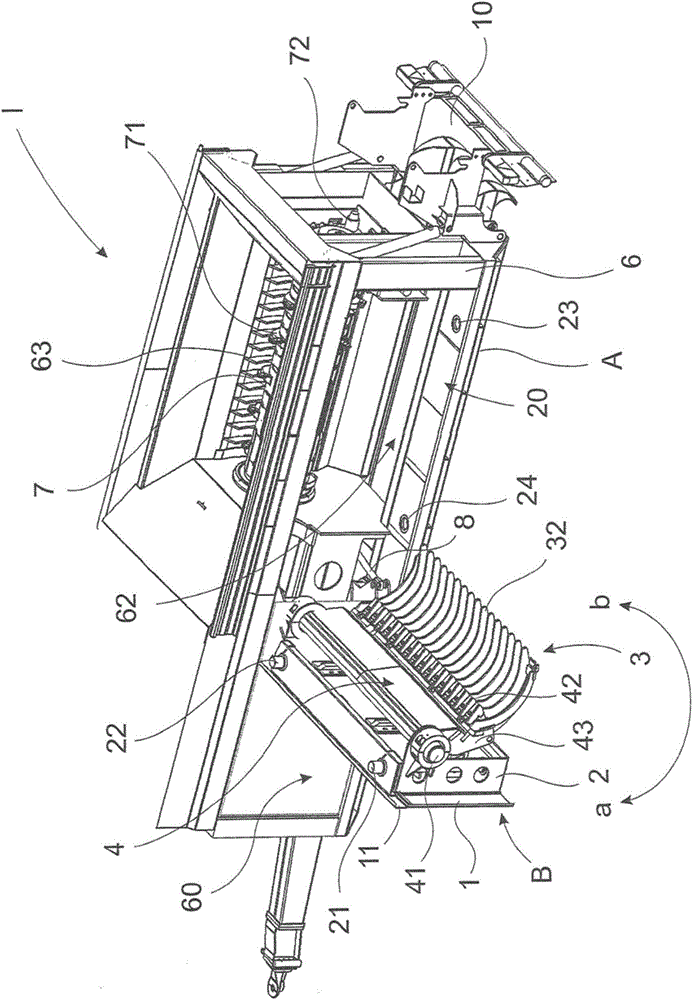

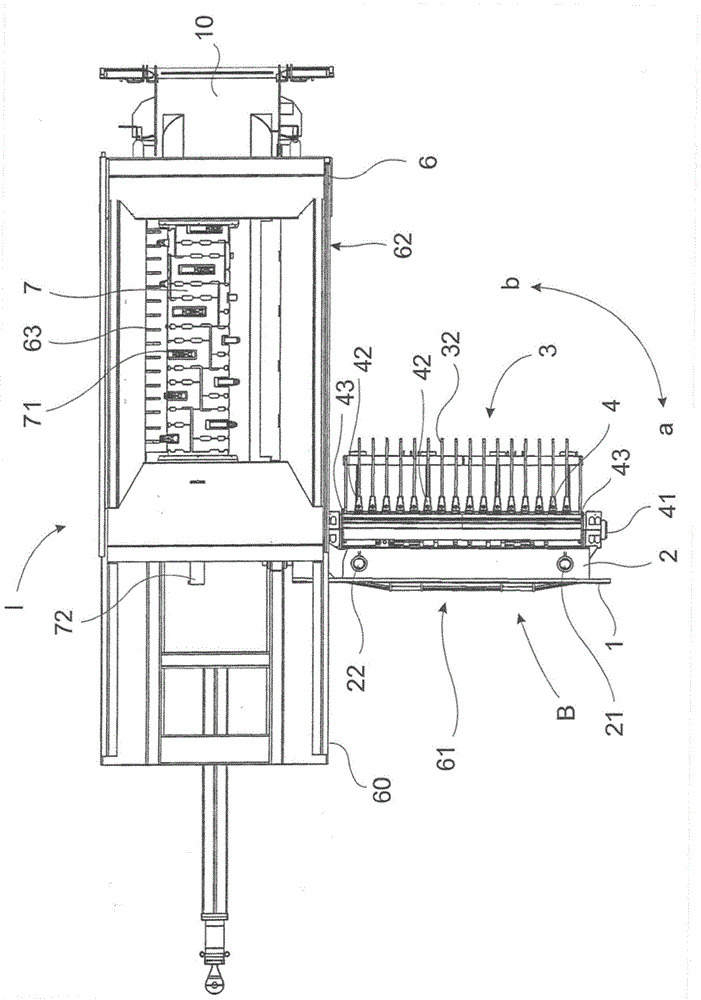

[0028] Figure 1aA schematic diagram showing a crushing device I according to the present invention without a screening device and when the common component B is in an outwardly pivoted position. The pulverizing device I and the common component B are each represented by an arrow. The casing 6 is mounted on a mounting surface A on the ground and / or a mounting plane, which is not shown in detail here. The mounting surface A is visible from the casing 6 in an upward direction. The common component B includes the wall 61 and / or the wall 60 that are part of the casing 6 . The non-pivotable part of the wall of the cabinet is referred to as the wall 60 . The pivotable common assembly B comprises a frame 2, such as Figure 1a As shown, the frame 2 is inserted into a part of the wall 61 through a guide 11 . A comb-shaped carrier 4 is disposed on the frame 2 , and a plurality of corresponding blades 42 are disposed on the comb-shaped carrier 4 . In addition, a comb carrier shaft 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com