Optical glass, preform and optical element

A technology of optical glass and preforms, applied in optical components, optics, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

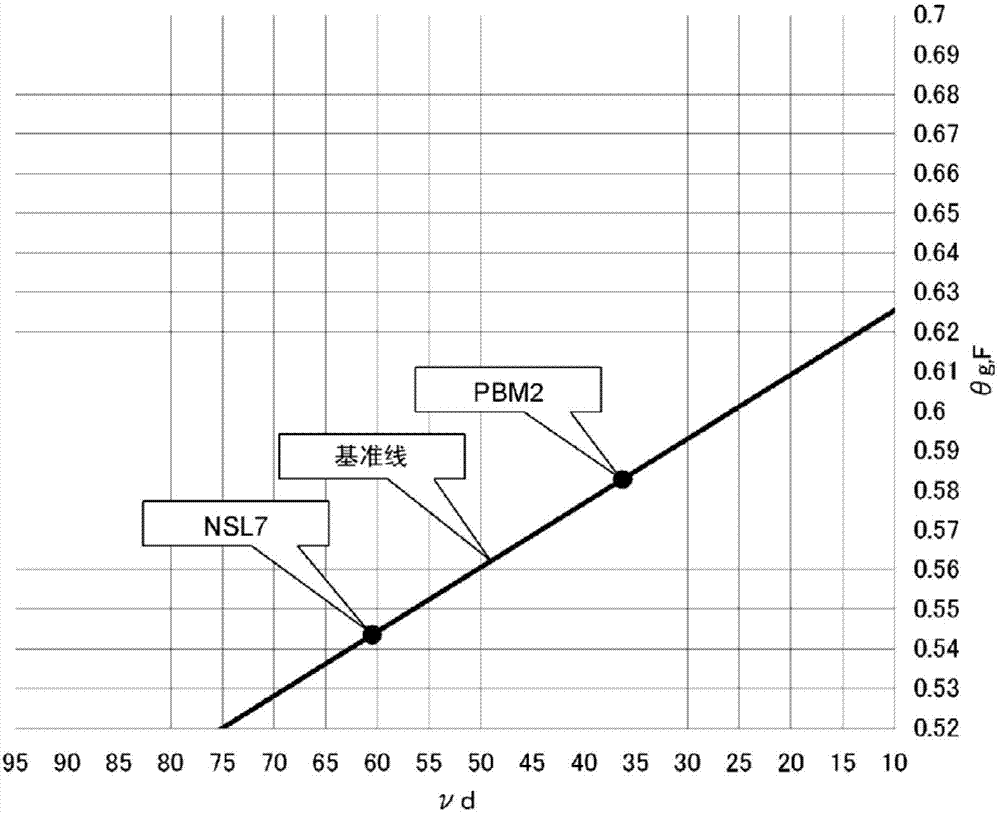

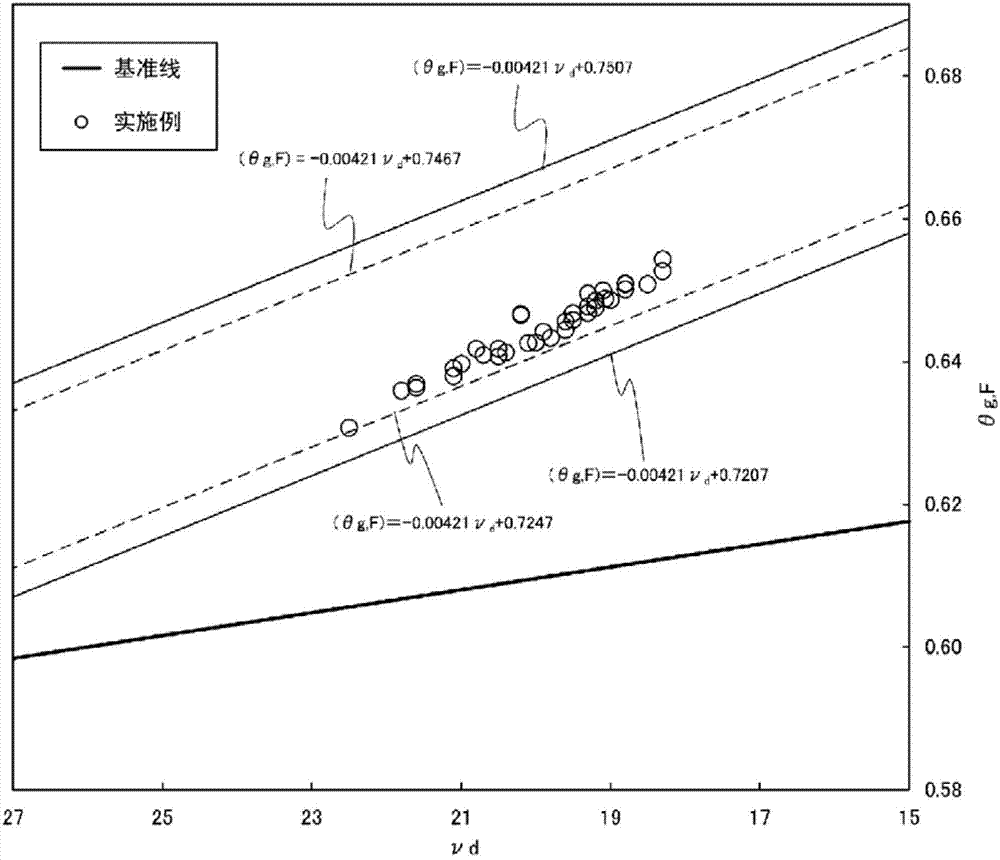

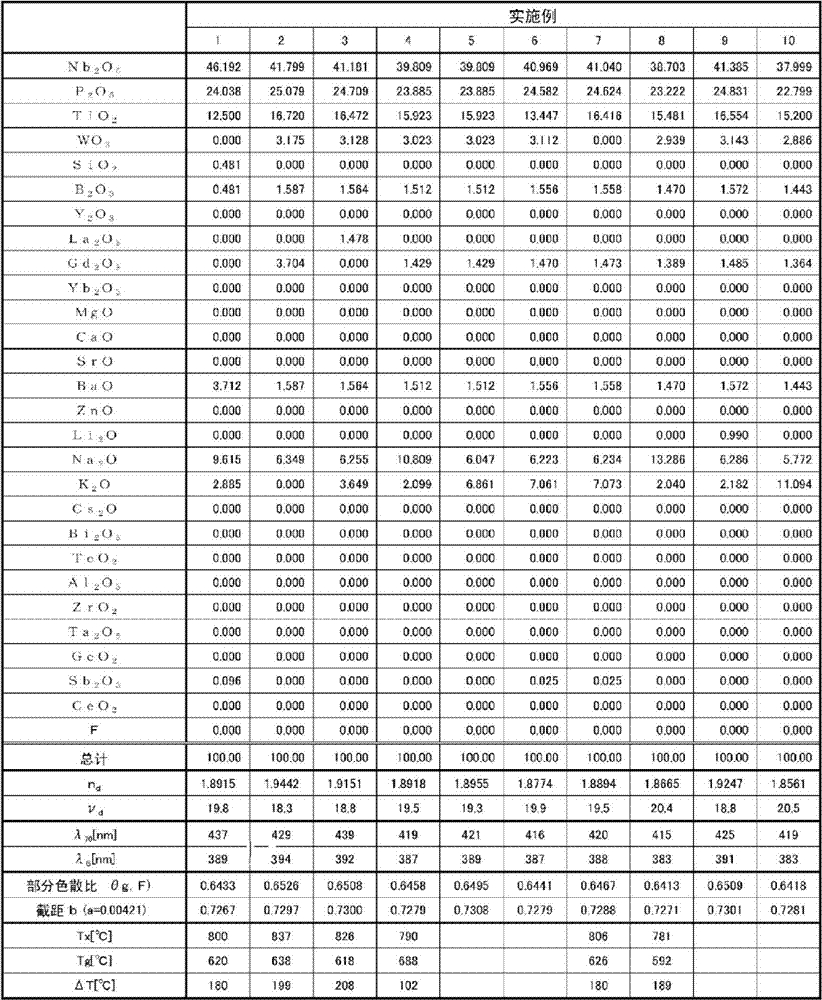

[0190] The glass compositions of Examples (No.1 to No.36) and Comparative Example (No.A) of the present invention and the refractive index (n d ), Abbe number (ν d ), partial dispersion ratio (θg, F), glass transition point (Tg), crystallization onset temperature (Tx), difference between glass transition point and crystallization onset temperature (ΔT), and spectral transmittance are shown as 70% and 5% of the wavelength (λ 70 , lambda 5 ) results are shown in Table 1 to Table 8. In addition, the Abbe number (ν d ) and the partial dispersion ratio (θg, F) are shown in figure 2 . It should be noted that the following examples are for illustrative purposes only, and the present invention is not limited to these examples.

[0191] The optical glass of the examples (No.1~No.36) of the present invention and the glass of the comparative example (No.A) are produced as follows: as the raw materials of each component, the respective corresponding oxides, hydroxides Carbonate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com