Bag breaking machine

A bag breaking machine and rack technology, applied in the field of environmental protection material sorting, can solve the problems of moving knife entanglement, inability to break bags, and low bag breaking efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

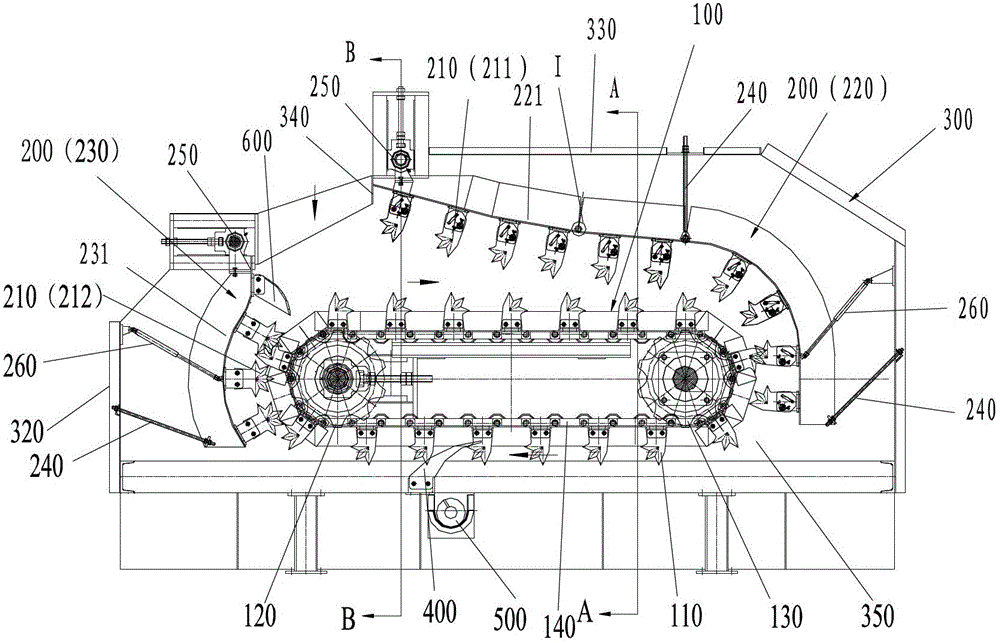

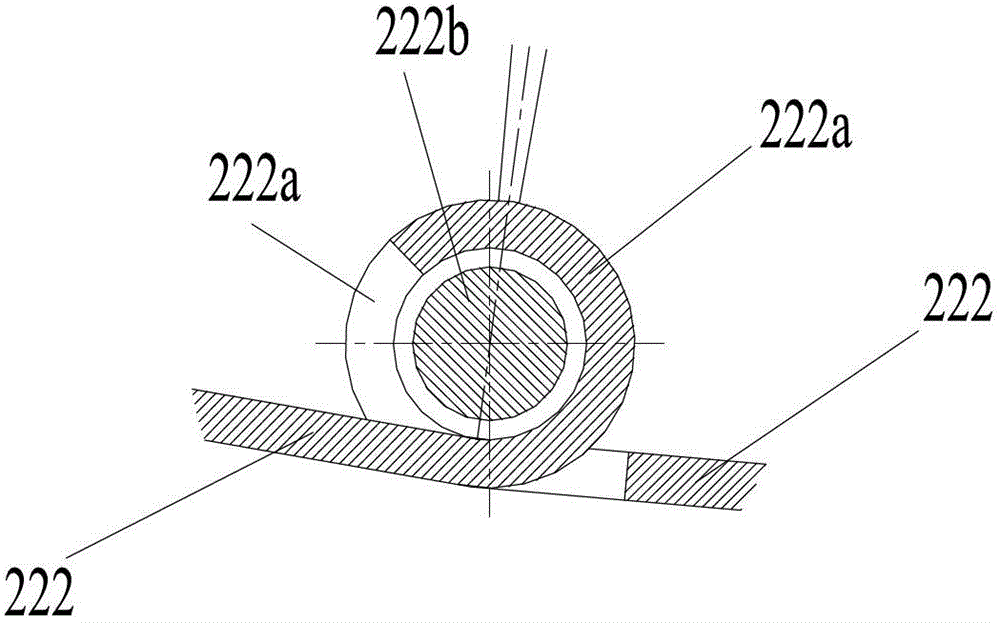

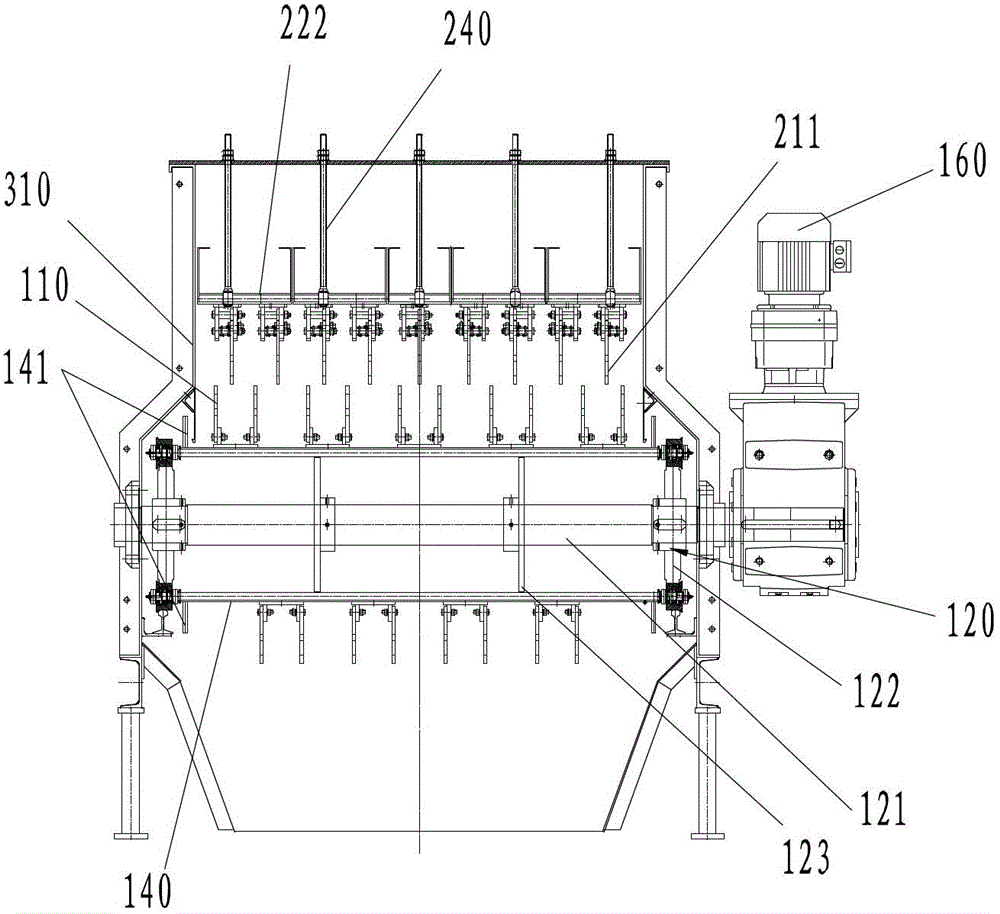

[0046] The bag breaking machine according to this embodiment includes a moving knife mechanism 100, a static knife mechanism 200 and other functional mechanisms, as follows Figure 1 to Figure 5 Describe in detail.

[0047] Moving knife mechanism

[0048] The moving knife mechanism 100 of the present invention adopts a chain transmission, and includes a chain plate conveying device and a plurality of moving knives 110 . The movable knife 110 is installed on the chain plate conveying device, and moves with the chain transmission of the chain plate conveying device. Due to the chain transmission, the diameter of the sprocket is much smaller than that of the roller, and the torque arm is shorter. When driven by a motor with the same power, the power output to the sprocket is much larger than that output to the roller, and the resistance is stronger. powerful. Therefore, the tearing force transmitted to the movable knife 110 is also stronger. Therefore, the moving knife mechan...

no. 2 approach

[0107] The bag breaking machine according to this embodiment includes a feeder 300' and a moving knife mechanism 100. The end in the feeding direction is arranged opposite to the feeder 300' at intervals.

[0108] Wherein, both sides of the feeder 300' can be closed in various ways, for example, a hopper 200' can be provided to realize it. Refer below Figure 6 and Figure 7 Describe the preferred embodiment with hopper 200', feeder 300', moving knife mechanism 100 and other functional mechanisms.

[0109] hopper

[0110] The hopper 200' is used to store materials, and the materials are piled up along the height direction of the hopper 200'. The upper part, the lower part and one side of the hopper 200' are open, the upper part is open for feeding, the lower part is open for setting the feeder 300' and closing both sides of the feeder 300', one side of the hopper 200' is open for setting Moving knife mechanism 100.

[0111] feeding machine

[0112] The feeder 300' can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com