Bag breaking and sorting equipment and method for food waste treatment

A technology for kitchen waste and bag breaking, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc. The effect of increasing the bag rate and improving the oil extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

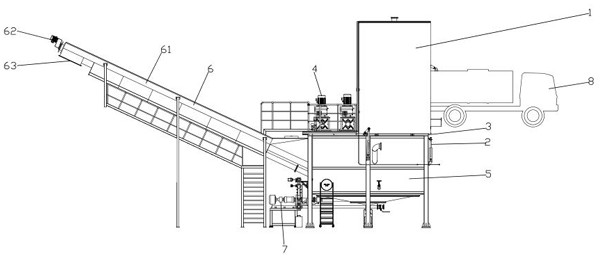

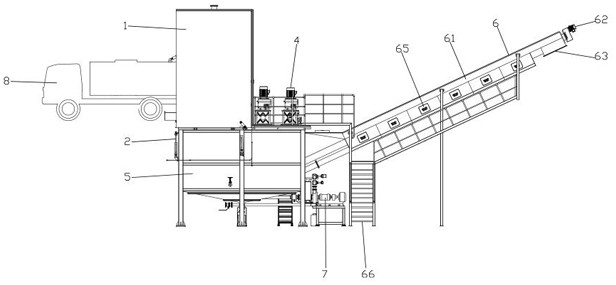

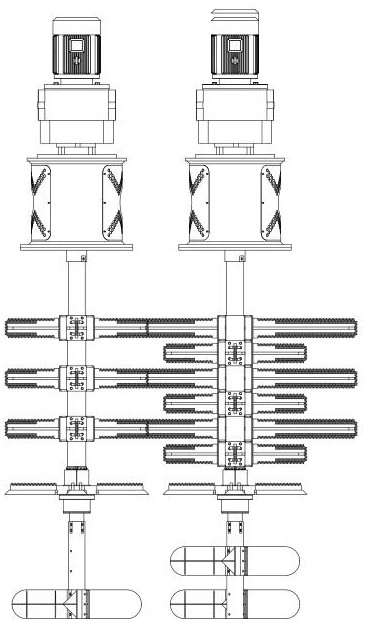

[0067] Example 1: The garbage truck is transported to the unloading hopper, the cover plate assembly 3 is opened by the oil cylinder 31 through the automatic control system, and the garbage truck unloads the kitchen waste into the unloading hopper; the pushing component 2 in the unloading hopper pushes the kitchen garbage To the barrel assembly 5; the kitchen waste is processed by the bag breaking blade 412, the slice 413 and the stirring blade 414 in sequence in the barrel assembly 5, and a large amount of slurry is screened out, wherein the first mixer 41 and the third mixer 43 are stirred clockwise, The second mixer 43 and the fourth mixer 44 stir counterclockwise to push the material forward; the cylinder body assembly 5 is provided with a heating assembly 53, and the heating assembly 53 uses high-temperature steam to heat the slurry to make the oil and kitchen waste liquid phase; the slurry passes through the cylinder The lower sieve plate enters the liquid collecting devi...

Embodiment 2

[0068] Example 2: Since the sand contained in the slurry will be hardened due to a long precipitation time, during the normal slurry discharge process, the slurry outlet and slurry outlet and backwash components 7 should be opened to ensure that the slurry in the funnel is not easy to precipitate. Stand still. Specifically, open the electric regulating valve 71, open the electric switch valve 72, close the electric switch valve 73, open the electric switch valve 74, and open the slurry pump 75, some of the slurry will self-circulate in the pipeline, and some will be discharged from the discharge pipeline. When it is used to backflush the bottom sand discharge pipe, open the electric regulating valve 71, close the electric switch valve 72, open the electric switch valve 73 and the electric switch valve 74, the flushing water enters the sand discharge pipe through the feed pipe, and the backwash slurry flows from the outlet. material pipe out.

[0069] The patent of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com