Lifting device for large cement pipe and construction method thereof

A construction method and cement pipe technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of high risk, difficulty in turning over, low efficiency, etc., and achieve the effect of wide application, ensuring construction safety, and smooth and free operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art.

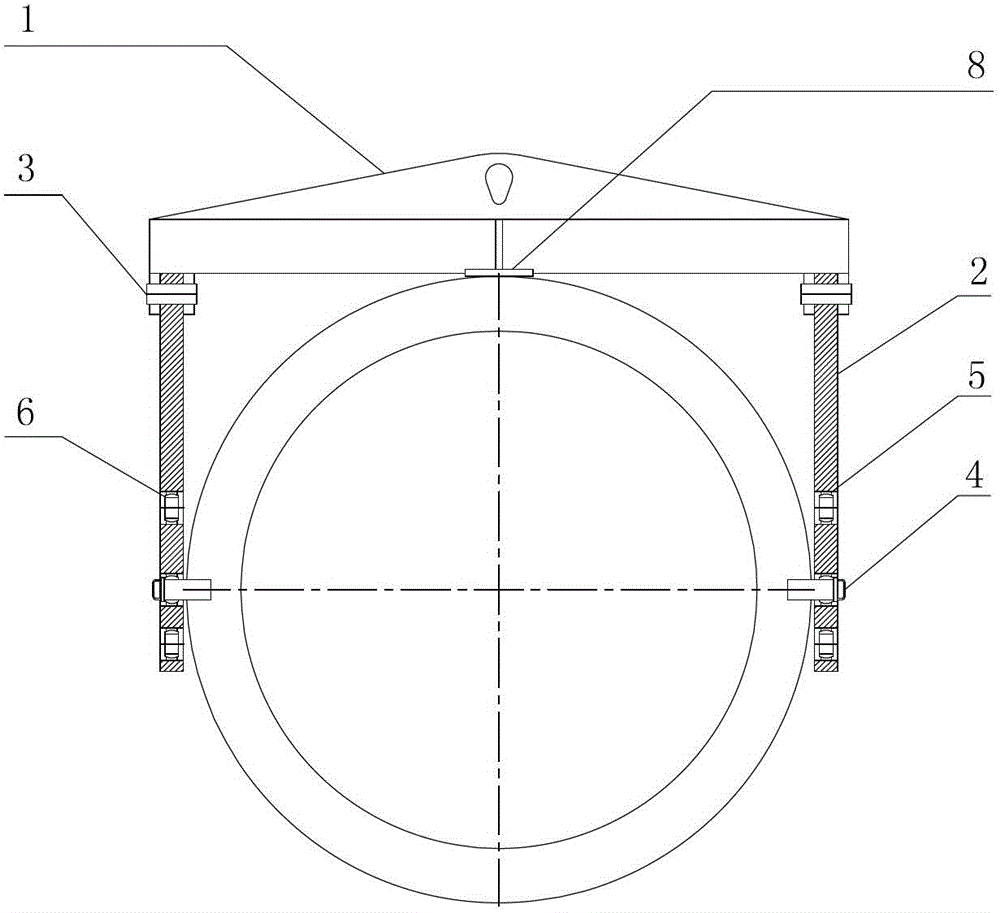

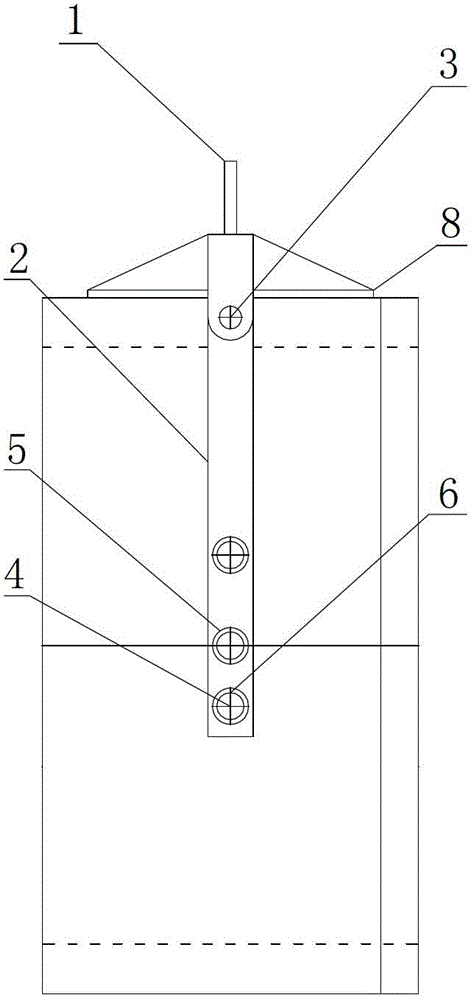

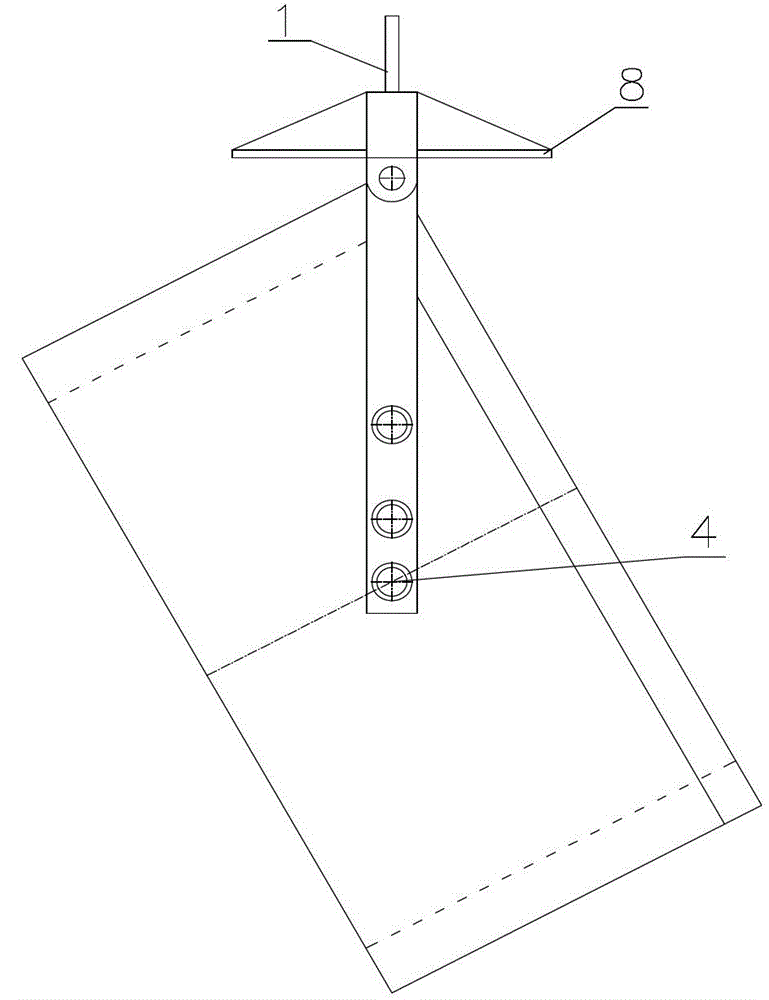

[0021] Such as figure 1 , 2 As shown, the cement pipe is laid flat, the horizontal beam (1) is hoisted above the pipe joint, the two vertical arms (2) naturally hang down on both sides of the pipe joint, and the round pin (4) is inserted into the pipe joint hoisting hole through the pin sleeve (5) The pipe joint is lifted inside, and the wing-shaped baffle (8) restricts the pipe joint from turning over and keeps the pipe joint stable. Such as Figure 5 As shown, the pin sleeve (5) is installed in the ball seat and can be rotated universally to facilitate the insertion and extraction of the round pin. Before lifting, insert the safety pin (7) to prevent the round pin from loosening and withdrawing, so as to ensure safe lifting.

[0022] Such as image 3 As shown, when the pipe joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com