Lifting system

A lifting system and lifting seat technology, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of difficult maintenance, inconvenient operation, complex structure, etc., and achieve the effect of stable work, cost saving and stable lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

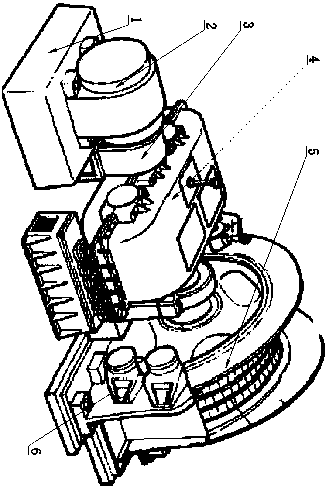

[0014] Such as figure 1 As shown, the object of the present invention is achieved in the following way: a hoisting and hoisting system includes a base 1, and a driving device is fixedly arranged on the base 1, and is characterized in that a reduction box is arranged beside the driving device, and the reduction gear The box is fixed on the ground through a fixed seat, a buffer device is provided between the fixed seat and the ground, a bracket is provided between the driving device and the reduction box, a shield is provided on the bracket, and the driving device passes through a coupling 3 It is directly connected with the reduction box, the other side of the reduction box is provided with a lifting seat 6, and the lifting seat 6 is provided with a wire reel 5, and several steel cables are arranged in the cable, and the output shaft of the reduction box is directly connected to the The input shaft of the wire reel 5 is connected, a reinforcing rib is arranged between the lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com