Universal rotating lifting appliance structure for hoisting

A rotating spreader and hoisting technology, which is applied in the directions of transportation and packaging, load hanging components, etc., can solve the problem of inconvenient rotation of the z-axis, and achieve the effect of convenient adjustment process, convenient adjustment and stable sling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

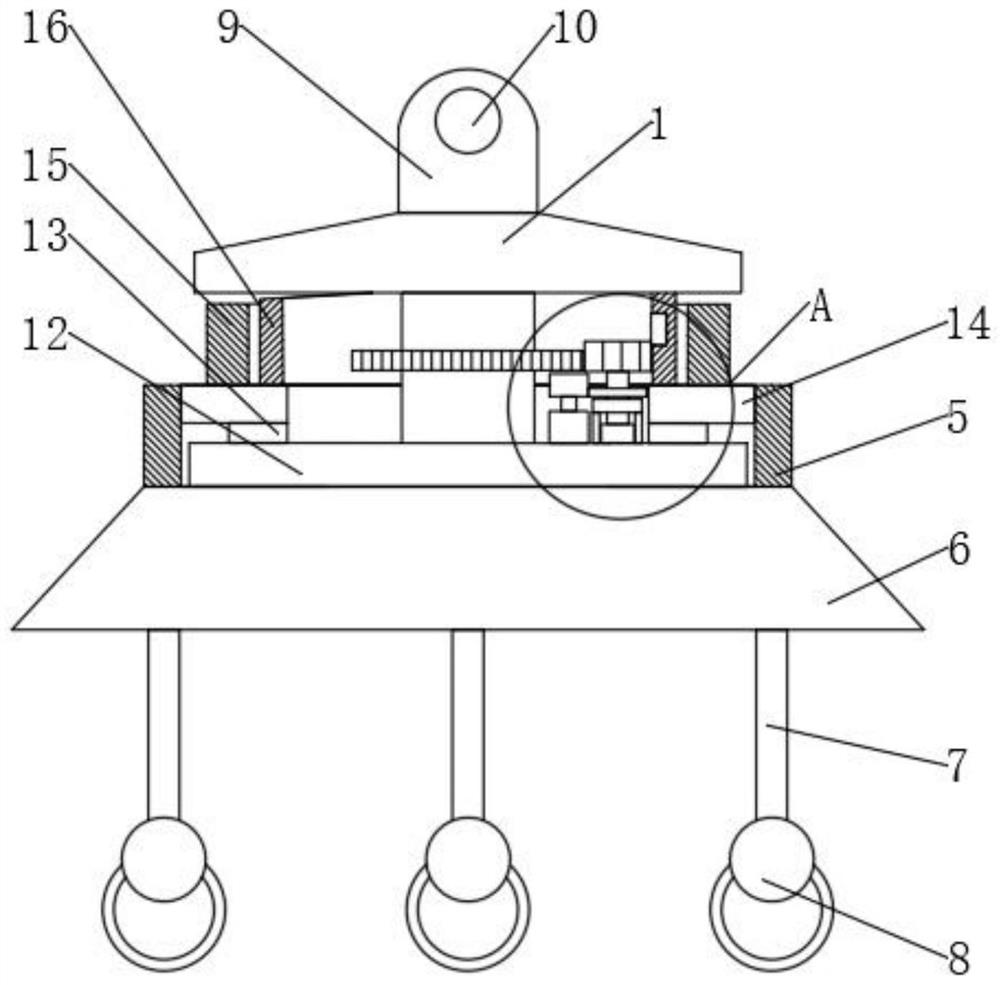

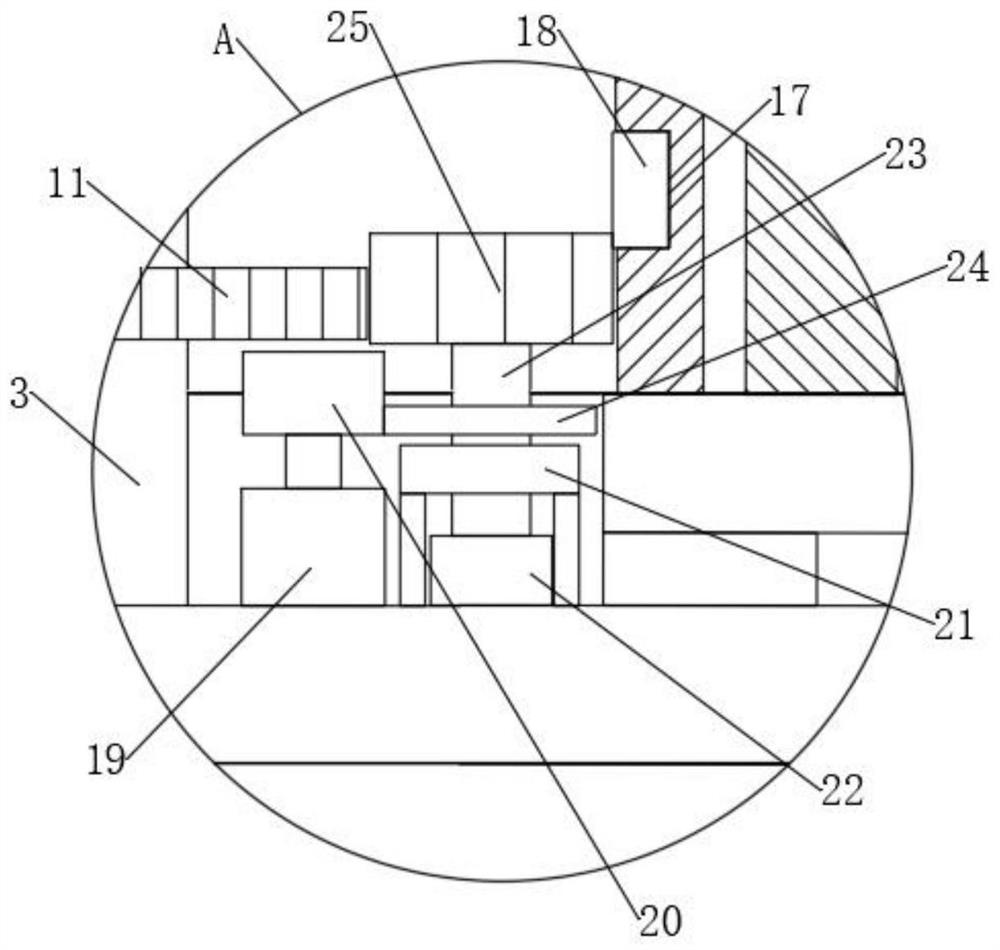

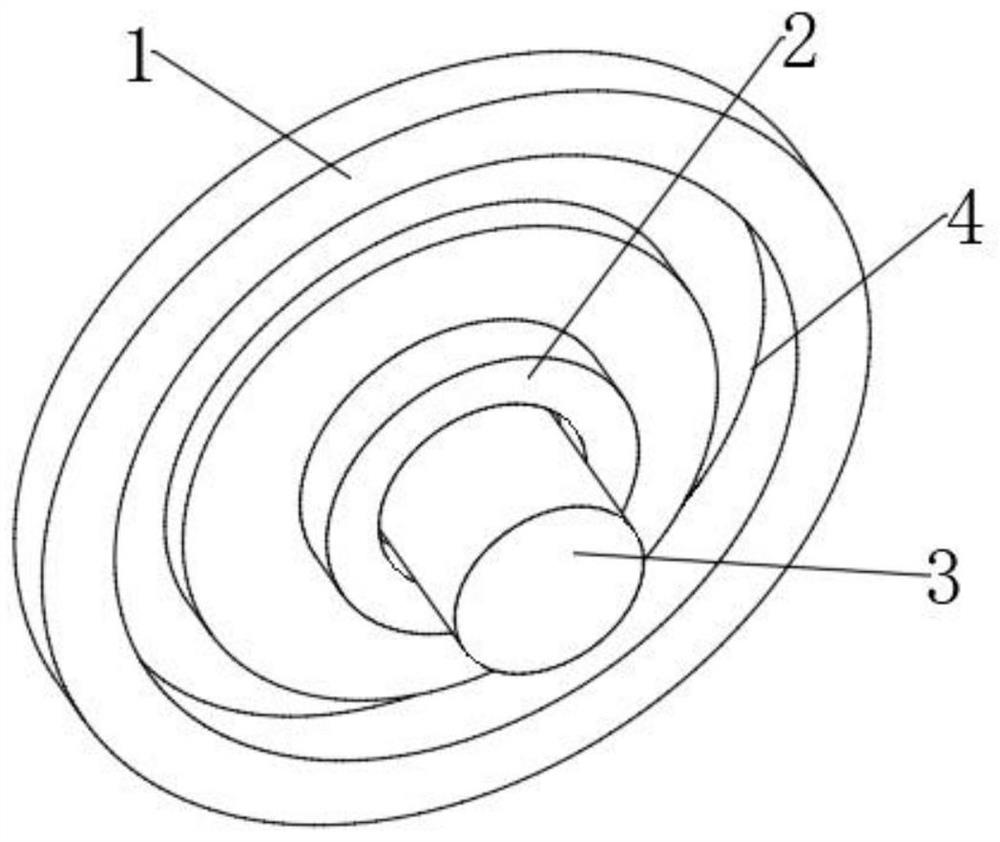

[0033] Such as Figure 1-5 As shown, the embodiment of the present invention provides a universal rotating spreader structure for hoisting, including a fixed plate 1, and the bottom of the fixed plate 1 is fixedly connected with a fixed connecting rod 3 through a fixed connection seat 2, so as to realize the connection between the fixed plate 1 and the fixed plate. The plates 12 can be rotated on the z-axis and tilted. The bottom of the fixed connecting rod 3 is movably connected to the bottom fixed plate 12, and the bottom surface and the side of the bottom fixed plate 12 are fixedly connected to the rotating disc 5. The inner side of the rotating disk 5 is fixedly connected with a first hydraulic thruster 13, the first hydraulic thruster 13 can push the bottom fixed plate 12 to move upwards, and then push the movable adjustment cylinder 16 to move upwards, the top of the first hydraulic thruster 13 is fixedly connected with The movable disc 14 is fixedly connected with a fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com