Experimental method for measuring distribution of breaking longitudinal force of steel rail of railway

An experimental method and longitudinal force technology, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of increasing experimental costs, difficult to control the temperature force, unfavorable longitudinal force distribution law of rail fracture, etc. The effect of shortening the experiment time and reducing the experiment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

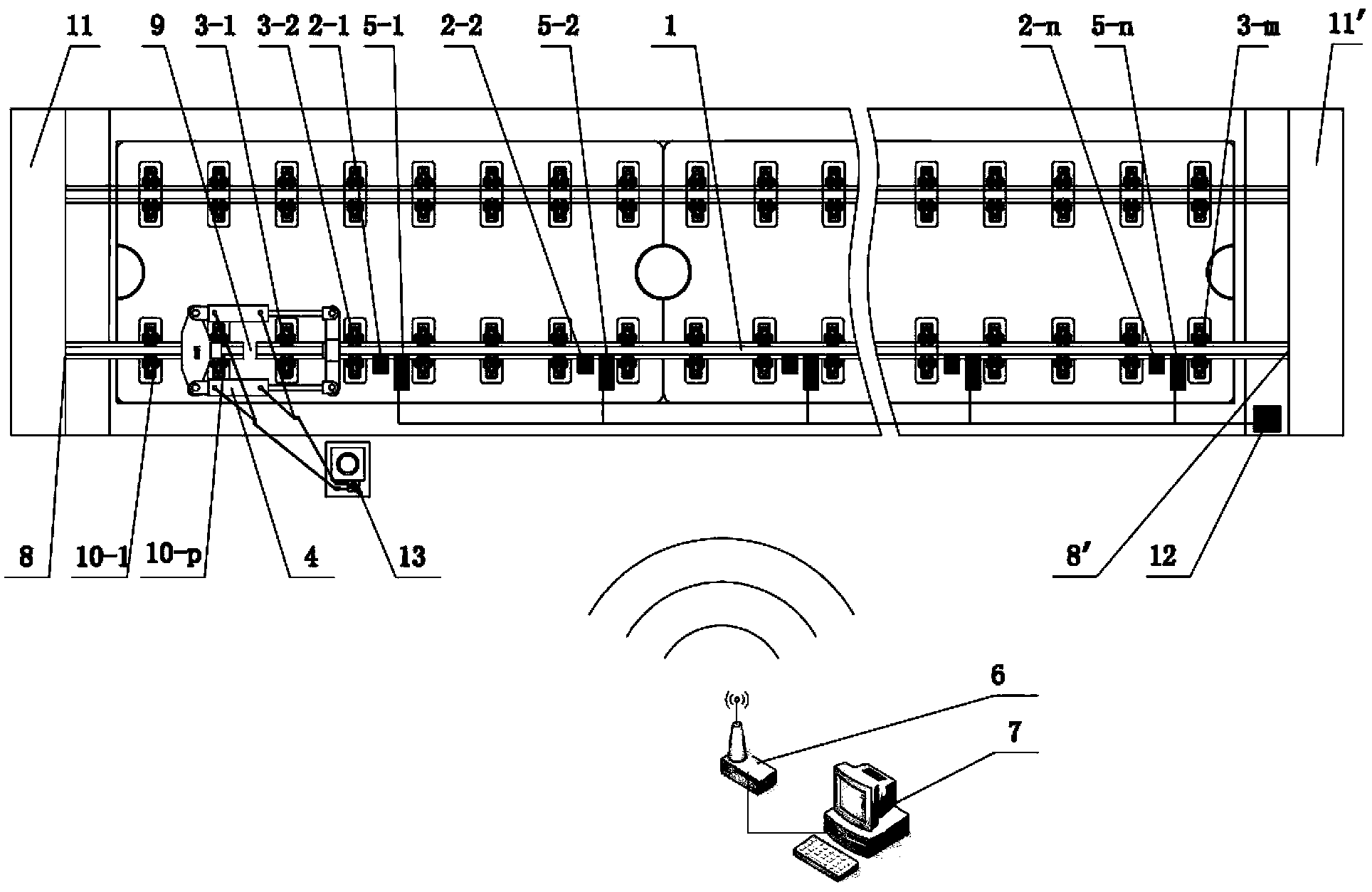

[0016] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solution and the drawings.

[0017] The present invention utilizes a rail tensioning machine to prestress the steel rail, and can accurately control the magnitude of the prestressing force through a load cell group installed on the rail, and can be converted to obtain corresponding values according to Hooke’s law and the relationship between solid thermal expansion strain and temperature Rail temperature change amplitude; after releasing the prestress, the force sensor group can measure the rail fracture longitudinal force distribution value under a certain rail temperature change amplitude or tensile stress.

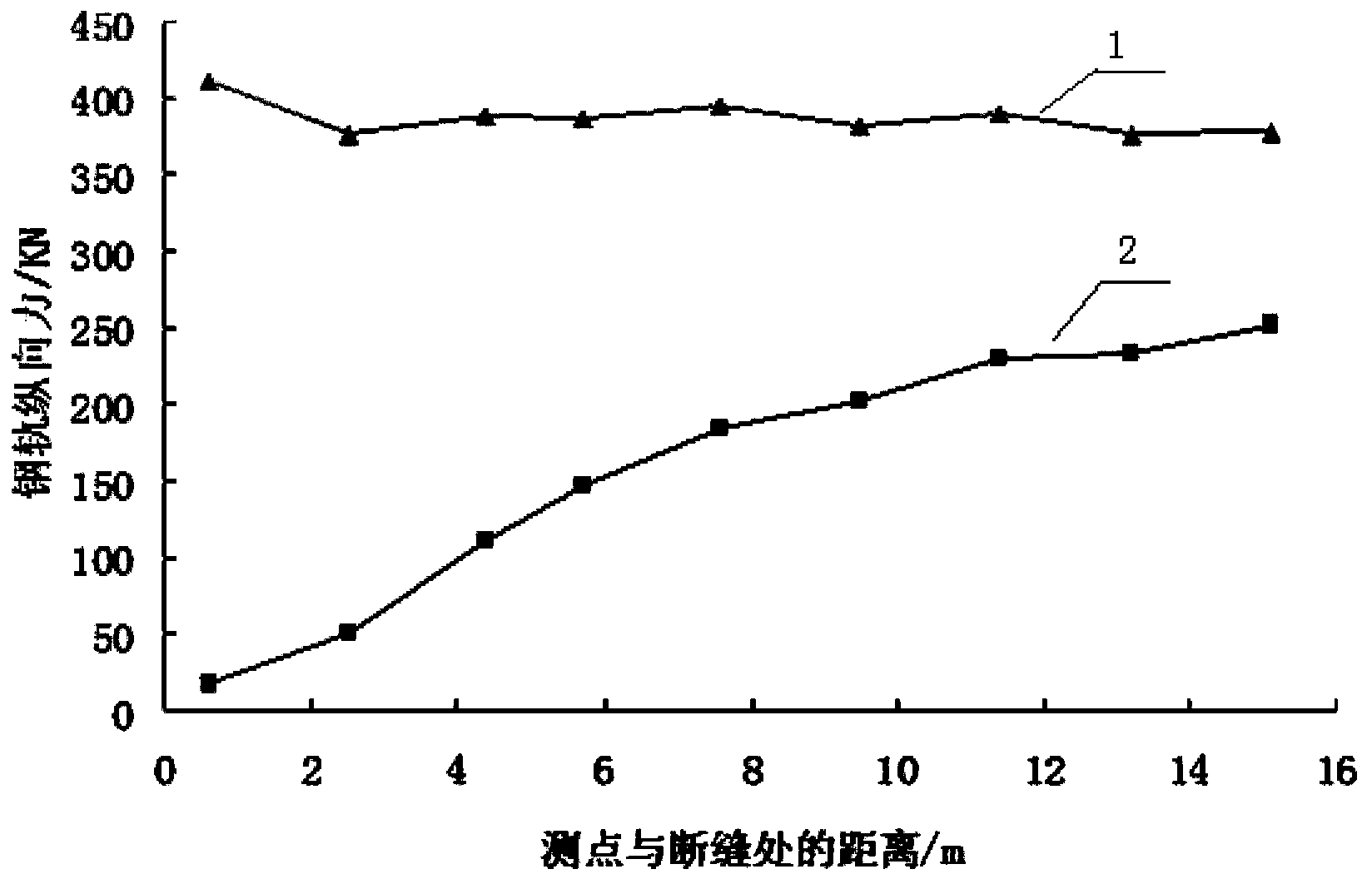

[0018] This example takes the longitudinal force distribution experiment of rail fracture when the rail temperature change amplitude is -21.3℃ as an example. The specific experimental method steps are as follows:

[0019] 1) Install force sensor group ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com