Method and rod forming device for producing coiled rods for the tobacco processing industry

A strip forming device and a technology of the processing industry, applied in the field of manufacturing coils, can solve the problems of increased consumption, cumbersome separation, increased finishing and reprocessing of injection materials, etc., and achieve the effect of short path and prevention of tobacco drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

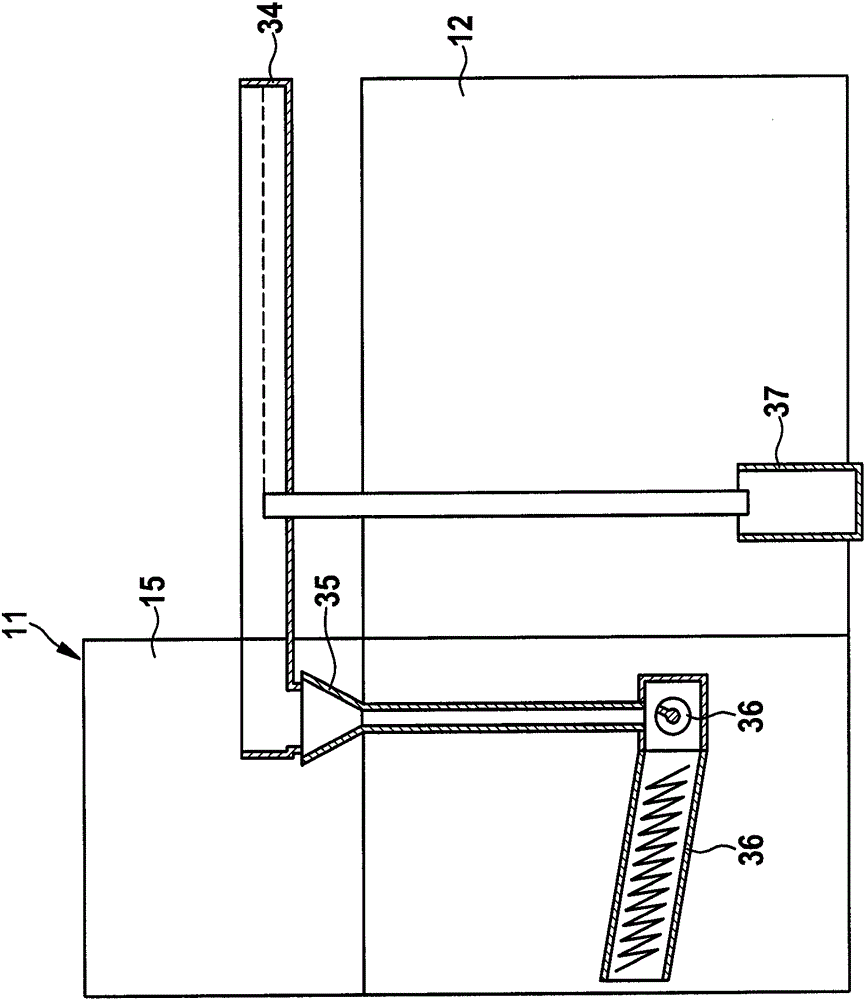

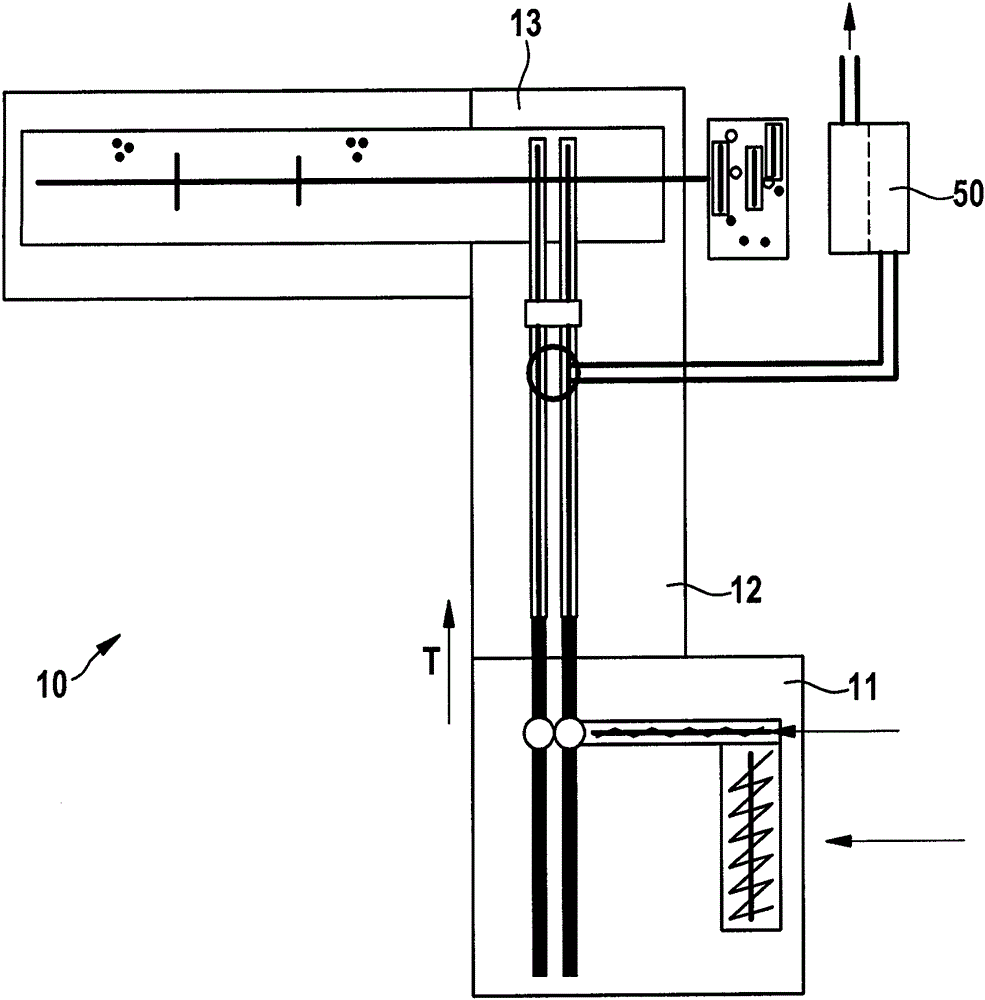

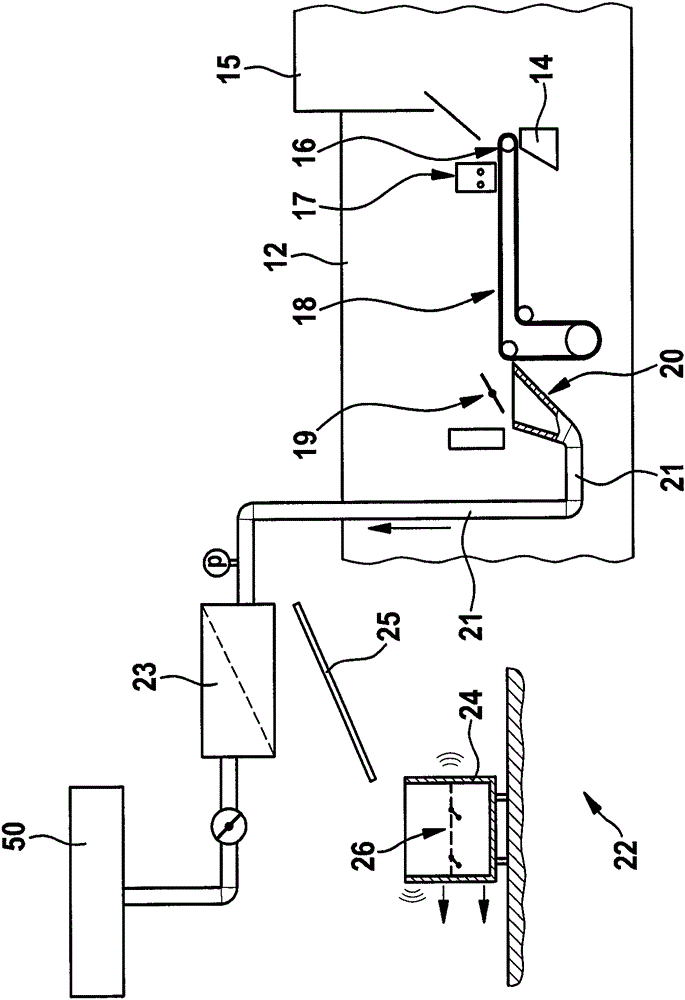

[0021] first in figure 1 In order to simplify the understanding of the invention, a conventional arrangement of a plant for the complete manufacture of a rod-shaped article, ie for example a cigarette, is shown in . exist figure 1 The apparatus 10 shown in FIG. 2 comprises dispensing means 11 , rod forming means 12 and optionally filter placement means 13 . The invention relates to the region of the slitting device 12 and, in another configuration, to the connection or coupling of the slitting device 12 to the recovery of the distribution device 11 . A known rod forming device 12 for the manufacture of rods for the tobacco processing industry comprises a mechanism 14 for supplying cigarette paper, a mechanism 15 for supplying tobacco, for example designed as a dispensing device 11, a mechanism for polymerizing cigarette paper and tobacco 16. Means 17 for gluing cigarette papers, means 18 for shaping cigarette paper-wrapped tobacco rods, for interrupting edge formation from r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com