Switching device of polish-grinding machine

A transfer device, grinding and polishing machine technology, applied in the direction of grinding/polishing equipment, grinding machines, machine tools suitable for grinding the edge of workpieces, etc., can solve the problems of incomplete transfer, easy drop of glass rhinestones, troublesome installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

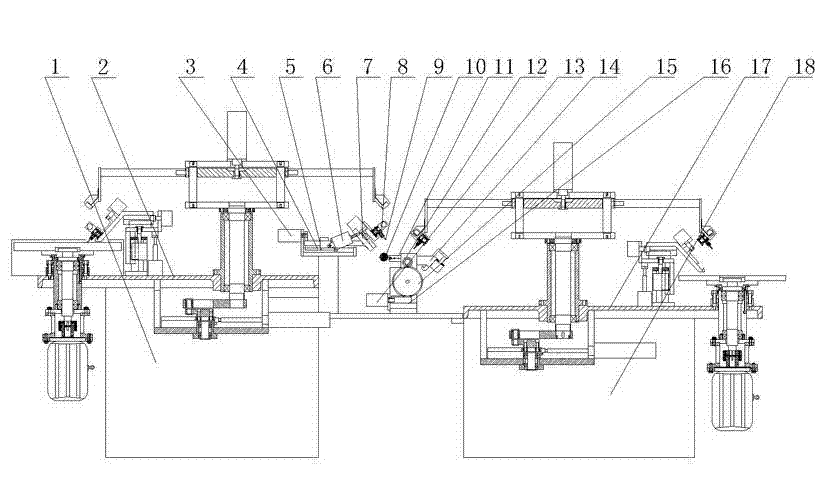

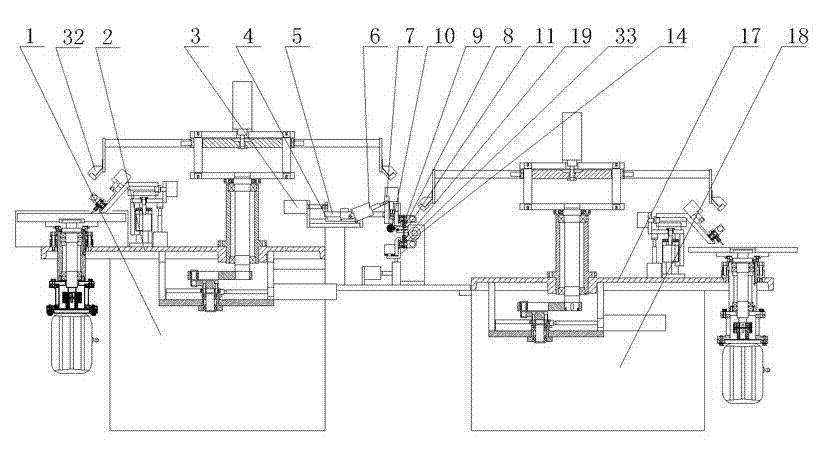

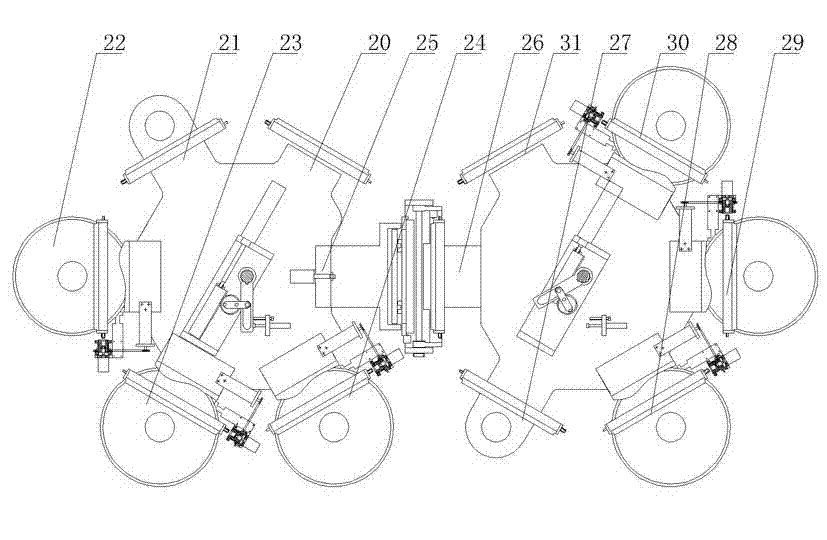

[0015] With reference to accompanying drawing, the adapter device of this grinding-polishing machine has first grinding-polishing machine 1 and second grinding-polishing machine 18, and described first grinding-polishing machine 1 and second grinding-polishing machine 18 are respectively provided with first Frame 2 and second frame 17, described first frame 2 has upper bead station 20, cooling station 21, coarse grinding station 22, fine grinding station 23, fine polishing station 24 and the first turn Connecting station 25, the second machine base 18 has a cooling station 27, a rough grinding station 28, a fine grinding station 29, a fine polishing station 30 and a beading station 31, and each station has a corresponding Clamping support, described first machine base 2 and second machine base 17 are provided with the fixture 32 corresponding with each station, and this fixture 32 is used for clamping or putting down mold 8, and mold 8 is provided with needle tube, and this nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com