Image forming apparatus, image forming method, and computer readable medium

An image and ejection position technology, applied in the direction of printing device, printing, etc., can solve the problem of consuming pre-ejection ink, etc., and achieve the effect of suppressing ink waste, preventing clogging, and preventing the decline of printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

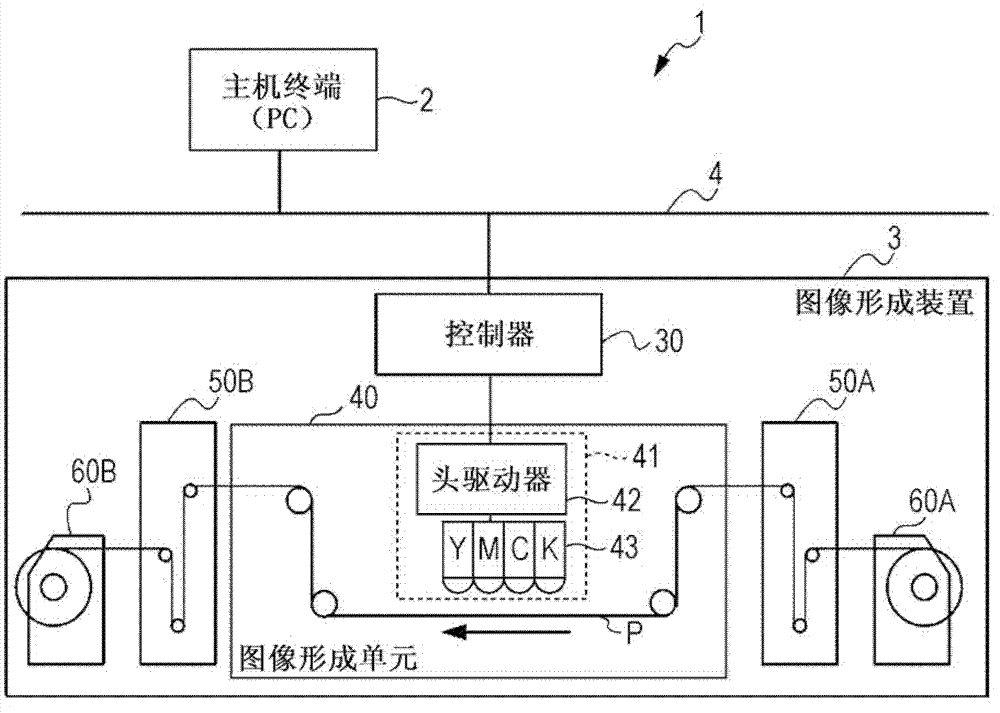

[0039] figure 1 is a diagram showing an exemplary schematic configuration of an image forming system 1 according to an exemplary embodiment of the present invention.

[0040] In the image forming system 1, a host terminal 2 such as a personal computer (PC) and an image forming apparatus 3 that performs printing with continuous paper P at high speed are connected to each other via a network 4 such as a local area network (LAN).

[0041] The image forming apparatus 3 is a printing apparatus that prints a print job (eg, a document) on continuous paper P at high speed in response to a print instruction supplied from the host terminal 2 , and includes a recording head 41 of a full line inkjet method.

[0042] The full line inkjet method is a method of performing printing by fixing the recording head in place, and by moving a continuous sheet of paper toward the recording head in a certain direction.

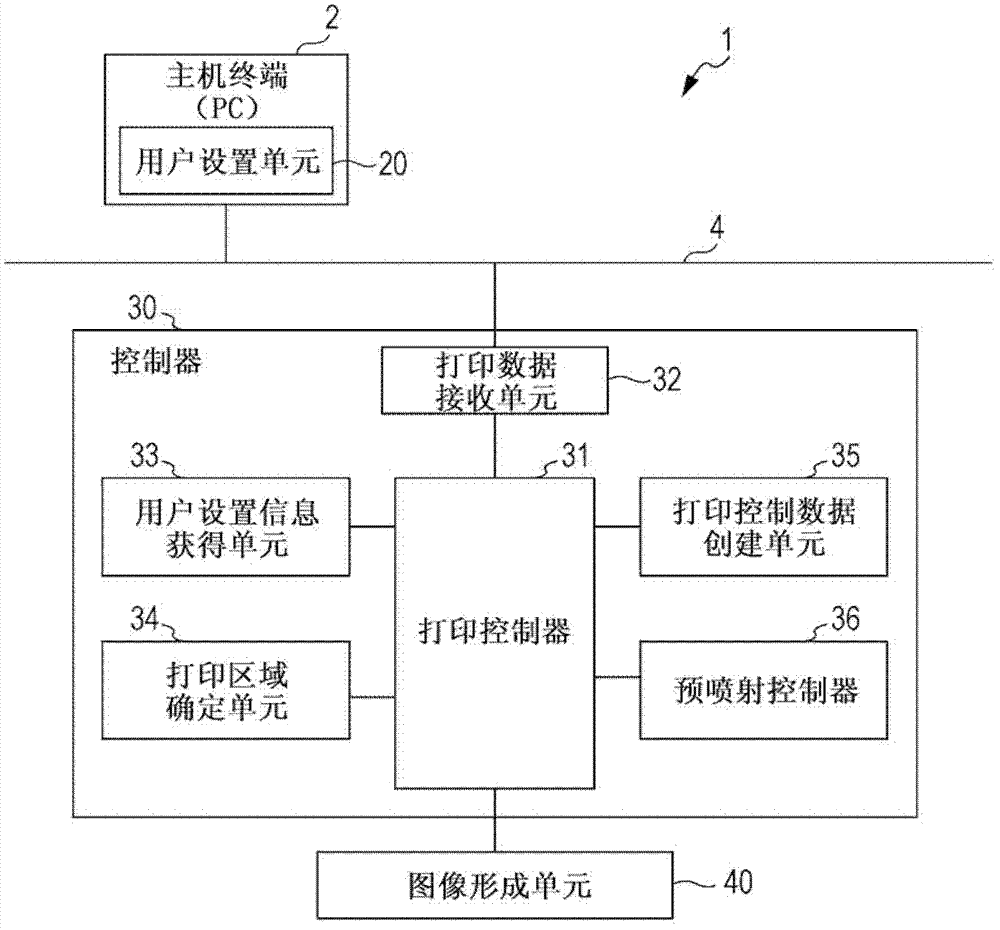

[0043] The image forming apparatus 3 includes a controller 30, an image forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com