Duplex printing apparatus

一种双面印刷、印刷机的技术,应用在打印装置、印刷、打字机等方向,能够解决装置大型、负担增大、设备费昂贵等问题,达到设备费降低、改善制品成本、产量增加的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

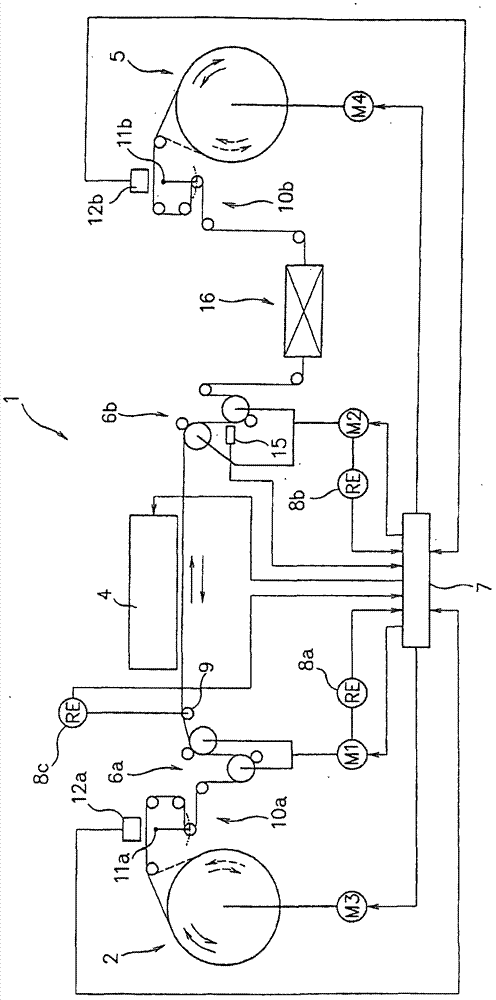

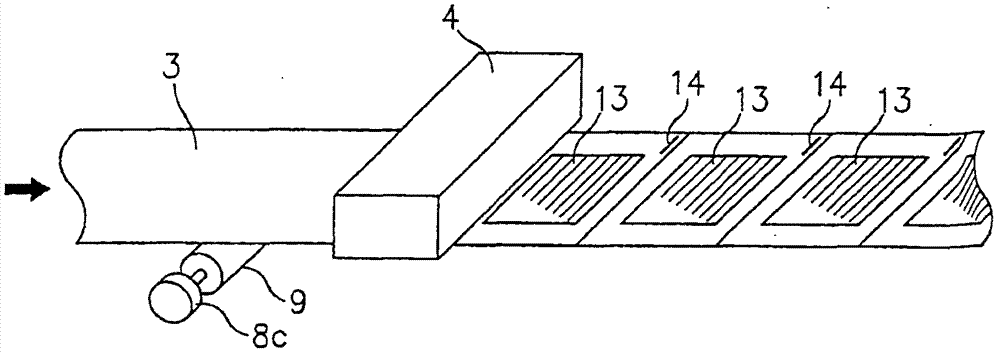

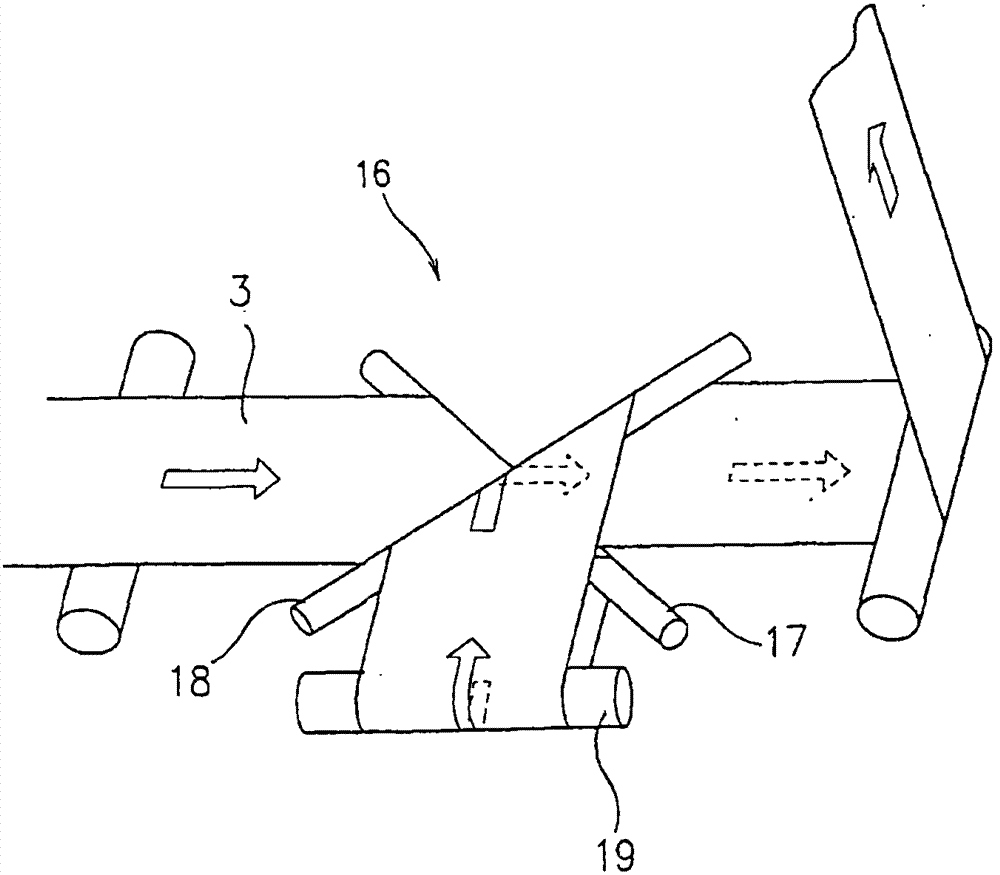

[0024] figure 1 A double-sided printing apparatus 1 of a first embodiment of the present invention is shown. The basic structure of this double-sided printing device 1 is that an inkjet printer 4 , which is an example of a digital printing machine, prints on the upper surface of a roll paper 3 supplied from a paper feeding unit 2 , and then winds it up by a winding unit 5 . In addition, moving the rolled paper 3 from the paper feeding unit 2 to the winding unit 5 is called forward feeding, and moving the rolled paper 3 in the opposite direction is called reverse feeding.

[0025] On the upstream side and the downstream side of the direction in which the above-mentioned roll paper 3 is fed in the inkjet printer 4, respectively, conveying roller devices 6a, 6b are separately controlled by the driving motors M1, M2 in a forward and reverse rotation manner. The two conveying roller devices 6a, 6b are controlled forwardly or reversely by their respective driving motors M1, M2, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com