Paper feeder and working method thereof

A technology of paper feeding device and working method, which is applied in the direction of sending objects, transportation and packaging, and thin material processing, etc. It can solve the problems of reduced surface quality of printed products, easy to scratch the surface of printed products, etc., and achieves safe printing and convenient operation , Improve the effect of product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

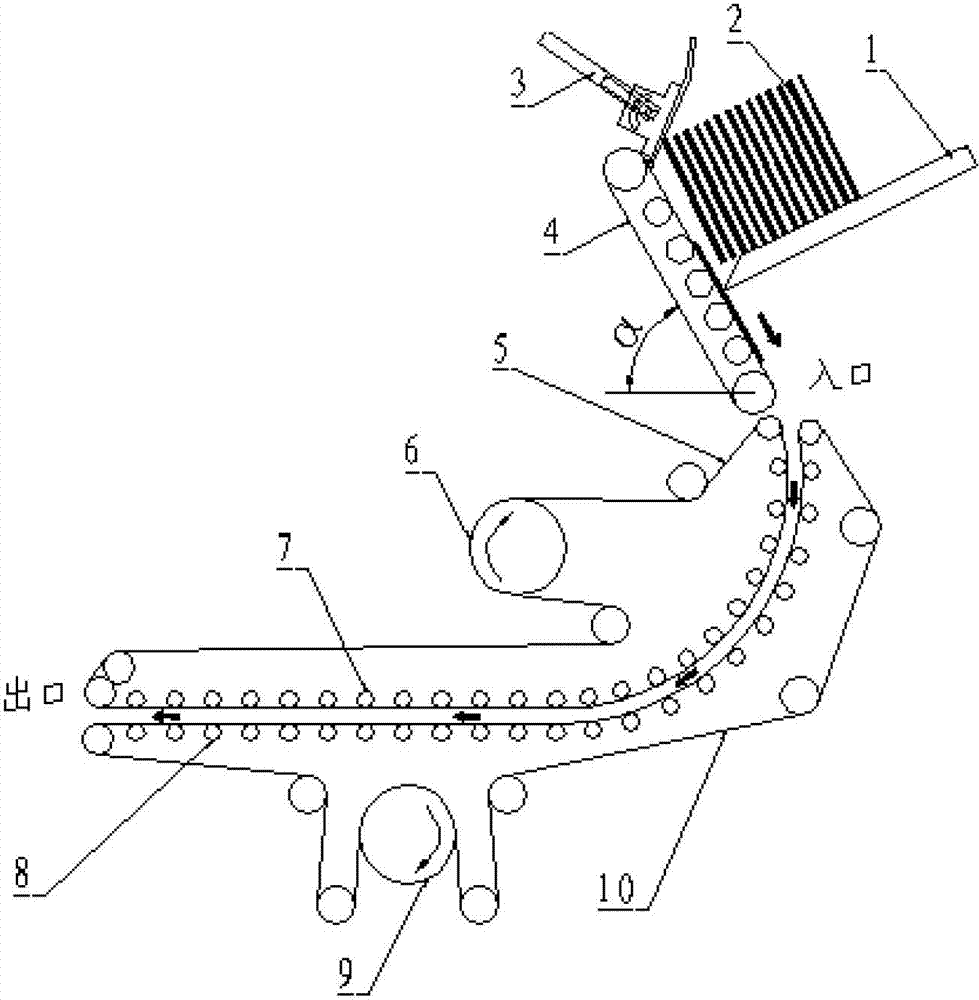

[0024] Embodiment 1: A paper feeding device (see attached drawing), which is characterized in that it consists of a paper feeding device with an inclination angle α and an overturning conveying device; the paper feeding device is installed at the entrance of the overturning conveying device.

[0025] The paper feeding device of the inclined angle α is composed of a paper feeding knife 1, a paper support frame 3 and a sending belt 4; the sending belt 4 is installed at the entrance of the overturning conveying device, and the printed paper pile 2 is placed on the sending belt 4; The paper feeding knife 1 blocks one end of the printed paper pile 2, and the other end of the printed paper pile 2 is held up by the paper holder 3; the single printed product is held and conveyed by the sending belt 4; the paper feeding device and the horizontal line form The angle α is 50-75 degrees. (see Attachment)

[0026] The angle α formed by the sending belt 4 and the horizontal line is 50-75 d...

Embodiment 2

[0039] Embodiment 2: A paper feeding device (see attached drawing), which is characterized in that it consists of a paper feeding device with an inclination angle α and an overturning conveying device; the paper feeding device is installed at the entrance of the overturning conveying device.

[0040] The paper feeding device of the inclined angle α is composed of a paper feeding knife 1, a paper support frame 3 and a sending belt 4; the sending belt 4 is installed at the entrance of the overturning conveying device, and the printed paper pile 2 is placed on the sending belt 4; The paper feeding knife 1 blocks one end of the printed paper pile 2, and the other end of the printed paper pile 2 is held up by the paper holder 3; the single printed product is held and conveyed by the sending belt 4; the paper feeding device and the horizontal line form The angle α is 60 degrees. (see Attachment)

[0041] The angle α formed by the sending belt 4 and the horizontal line is 60 degrees...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com