Lubricating horsehead pin of oil pumping machine

A donkey head pin and pumping unit technology, which is applied in the direction of engine lubrication, mechanical equipment, engine components, etc., can solve the problems of complicated maintenance of donkey head pins, inconvenient turning and disassembly of donkey head pins, etc., and achieve simple maintenance , to avoid the effect of rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the implementations shown in the drawings, but it should be noted that these implementations are not limitations of the present invention, and those of ordinary skill in the art based on the functions, methods, or structural changes made by these implementations Equivalent transformations or substitutions all fall within the protection scope of the present invention.

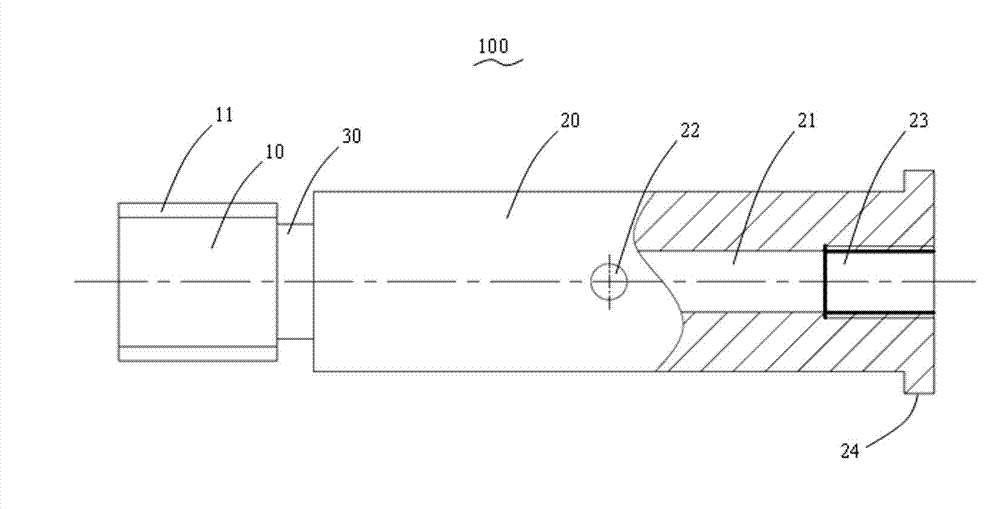

[0020] Please refer to figure 1 as shown, figure 1 It is a partial cross-sectional view of a specific embodiment of a lubricated donkey head pin for a pumping unit of the present invention. In this embodiment, a lubricated donkey head pin 100 for an oil pumping unit includes: a first pin body 10 , a second pin body 20 and a connecting portion connecting the first pin body 10 and the second pin body 20 30.

[0021] In this embodiment, the surface of the first pin body 10 is provided with an external thread 11 for being screwed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com