Double-helix feeder

A feeder and double-screw technology, applied in the field of feeding devices, can solve the problem that the conveyor belt cannot feed viscous materials, and achieve the effect of ensuring efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

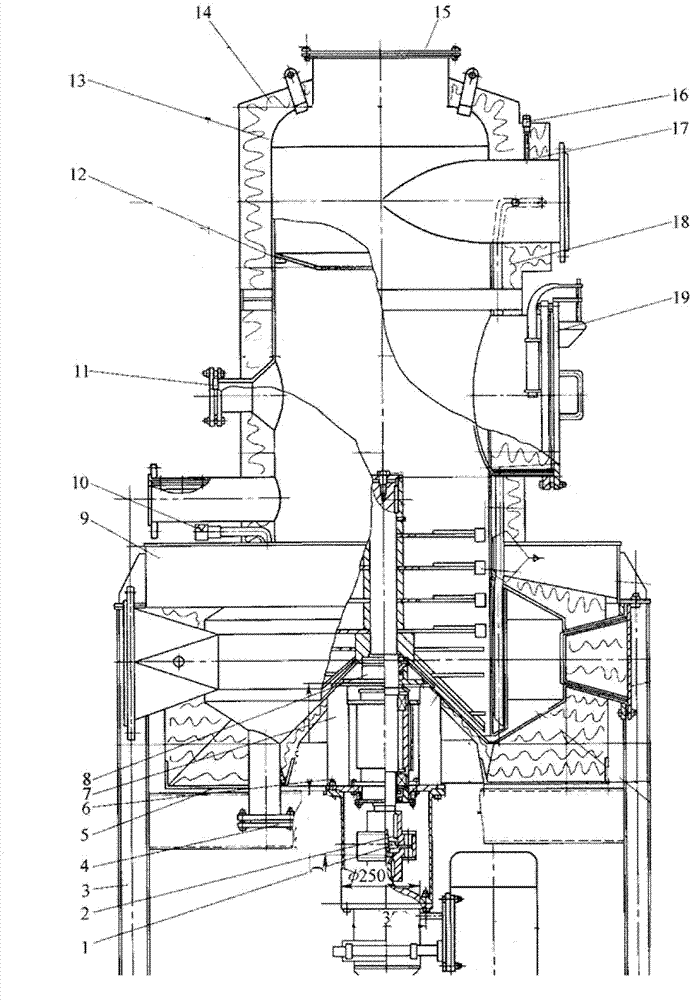

[0010] Such as figure 1 As shown, the double-screw feeder of the present invention includes a support 1, a feed bin 8, a screw propeller 6, a lower drive shaft part 2, an upper drive wheel part 11, a speed reducer 13, and a speed-regulating motor 18, wherein the feed bin 8 The outlet of the outlet corresponds to the screw propeller 6, and the blade at the center of the bin 8 is driven by the spinning shaft component 5, and the cross connection between the spinning shaft component 5 and the screw propeller is provided with a sealing plate 7 and a sealing sleeve 19, and the spinning shaft The component 5 is connected and driven by the bevel gear set 4 and the lower tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com