Detection jig for vehicle decorative strip

A technology for automotive decorative strips and testing fixtures, applied to measuring devices, instruments, etc., can solve problems such as poor stability, long time consumption, and inconvenient measurement, so as to facilitate measurement and detection, improve detection accuracy, and improve detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

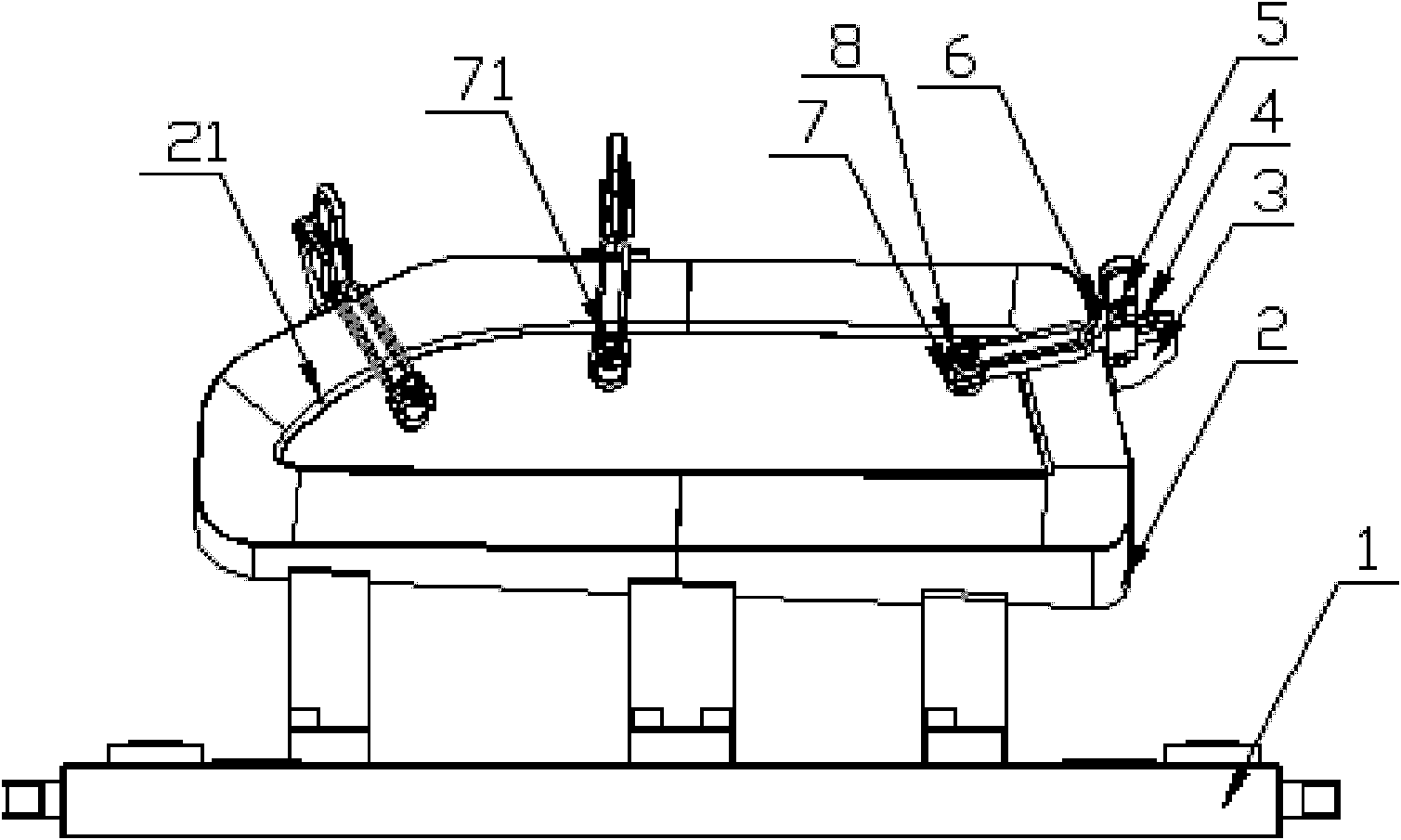

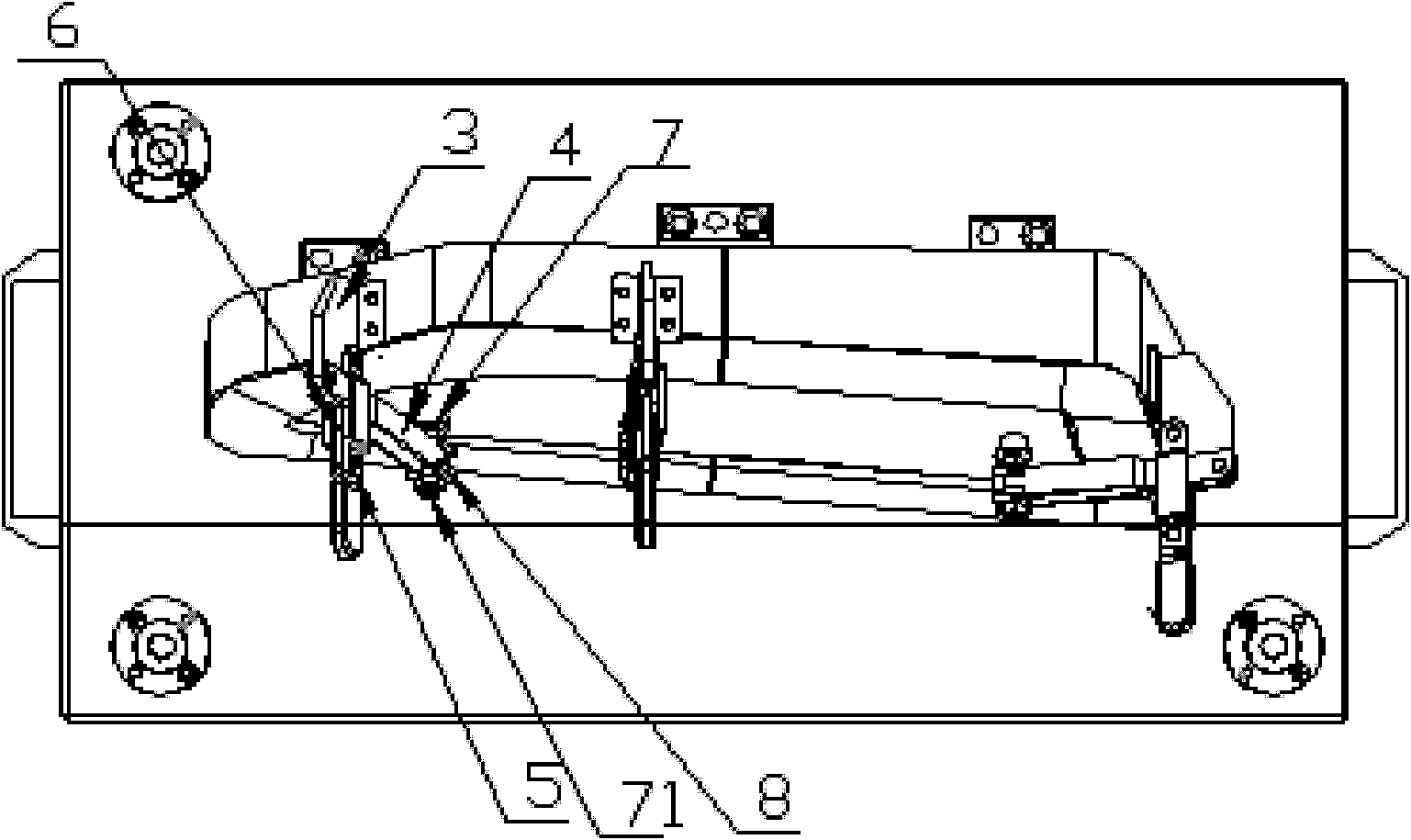

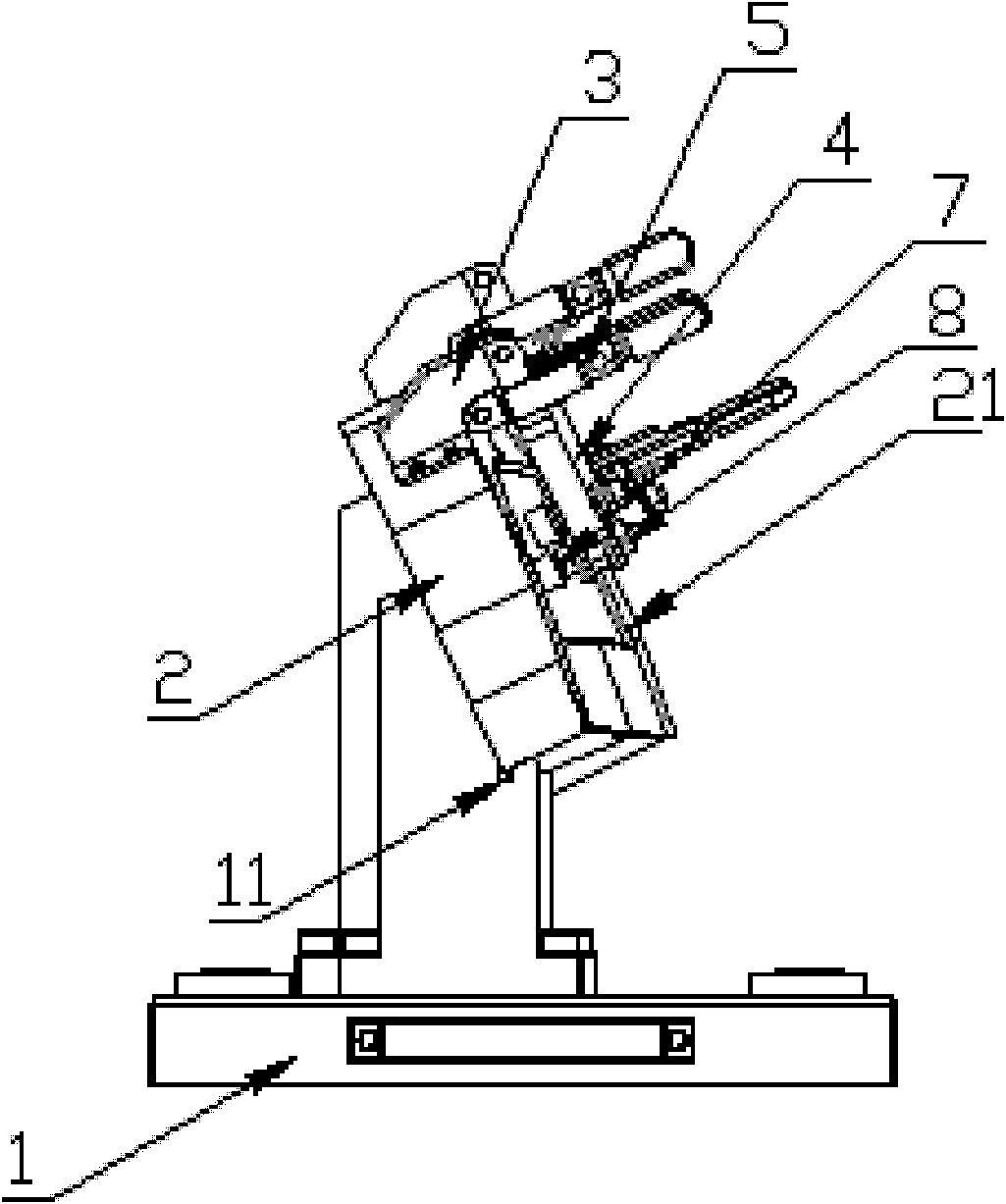

[0014] Embodiment: A car trim detection fixture, including a base 1, a lower mold 2 and a fixing frame, the lower mold 2 can be disassembled and fixed above the base 1, and the upper side of the lower mold 2 is provided with a Positioning slot, several fixing frames can be disassembled and fixed on the lower mold 2, the moving end of the positioning frame can move longitudinally and can maintain a stable braking state and is located directly above the positioning slot of the lower mold 2. When using, first place the car trim Fit and position in the positioning groove of the lower mold 2, then the moving end of the fixed frame descends longitudinally to press and fix the car trim, and the moving end of the fixed frame presses the car trim to maintain a stable braking state, and at this time Car trims can now be measured to exact dimensions using the measuring tool.

[0015] The structure that the lower mold 2 can be disassembled and fixed on the top of the base 1 is as follows:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com