Torque calibrator for torque wrench

A technology of torque wrench and calibrator, which is applied in the direction of force/torque/power measuring instrument calibration/testing, instrumentation, machine/structural component testing, etc., and can solve the negative effects of fast calibration of unfavorable torque wrench torque and accuracy of measurement data , long invalid working time and other problems, to achieve the effect of shortening the calibration time, avoiding negative effects, and quickly calibrating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

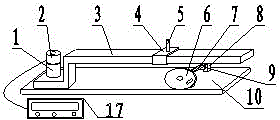

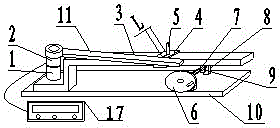

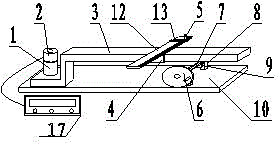

[0020] See Figure 3 ~ Figure 5 , The present invention includes a bottom plate 10, a mechanical auxiliary force adding mechanism, a measurement execution mechanism and a data display mechanism 17. The mechanical auxiliary force-increasing mechanism is composed of an after-increasing hand wheel 6, a screw 7, a screw support 8, a screw slider 9, an afterburner arm 3, an afterburner arm slider 4, and a wrench push rod 5. The afterburner handwheel 6 is connected with the lead screw 7. The lead screw 7 is fixed on the bottom plate 10 through the screw support 8 at both ends. The lead screw slider 9 is sleeved on the outside of the lead screw 7. The two form a threaded transmission mechanism. The afterburner arm 3 is assembled with the screw slider 9, and the afterburner arm slider 4 is assembled with the afterburner arm 3. The measurement actuator includes a torque sensor and a rotating shaft, and the torque sensor is fixedly installed on the rotating shaft; the data display mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com